Herb Dryers

Herb Dryers use fluid beds to evenly distribute airflow to suspend and fluidize product, like ping-pongs ball over airstreams. Heat is used to improve performance, but because it is not the primary driver of evaporation, does not burn the oils like other popular methods. Because fluid beds perform best with shredded material, they are ideal for pre-rolls and extraction biomass. Trichomes lost to abrasion are captured and returned to product in real time.

| Throughputs |

500 – 3,500 lbs/hr |

| Herb Extract Retention | ~90.5% |

| Made In | USA |

Operating Principle

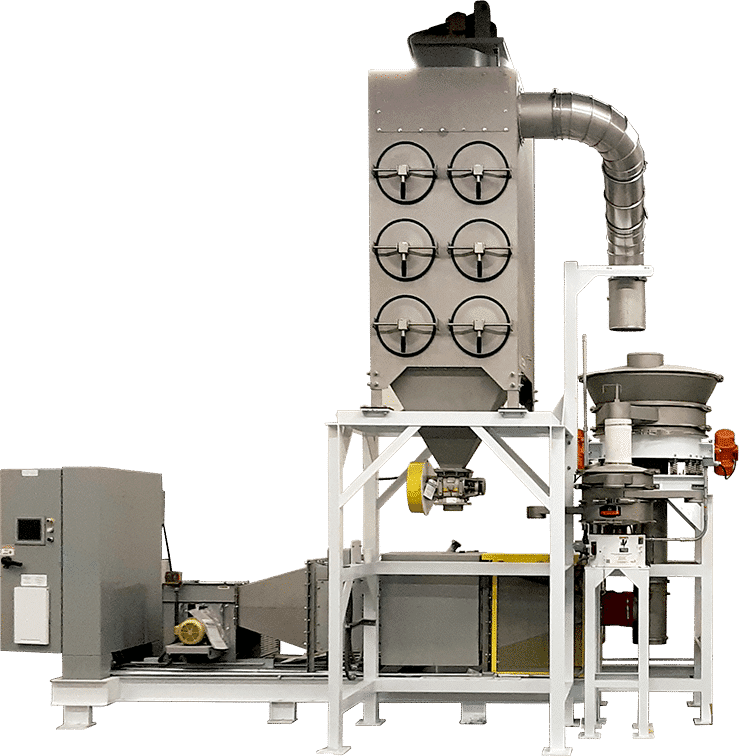

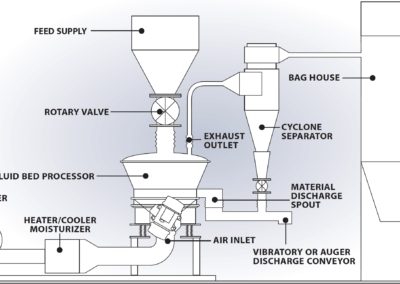

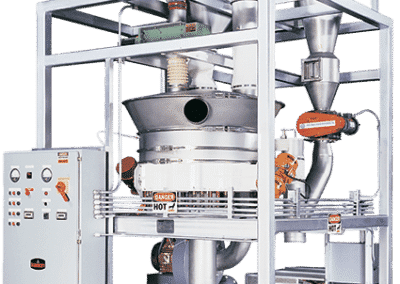

Fluid bed dryers use air traveling at a rate just higher than the product’s terminal velocity, suspending the product above the grate. The large amount of dry air passing through the product achieves the same dry-rate as rotary (tumble) dryers without the use of high temperatures. Fluid beds are available in 48” to 7’ diameters, achieving a throughput of up to 3,500 lbs/hr. The circular design of these fluid beds maximizes space and energy consumptions and is significantly easier to clean than rectangular makes. The system’s closed-loop, thoroughly engineered layout and components allows for recapture of VOCs and easy dis-mantle and reassembly of key components. Because they require homogenized product and can degrade product by up to 2 points, they’re most popular for extraction biomass and pre-rolls.

Standard Inclusions

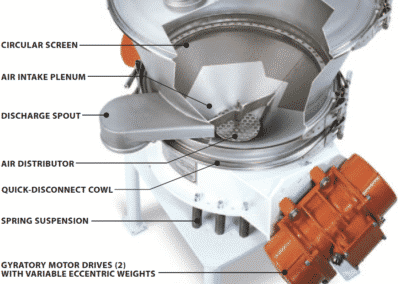

- Adjustable Weir (with plough) will be provided to vary bed depth and control retention time

- 304 Stainless Steel Material Contact Parts with glass bead finish

- Each equipped with a Perforated plate Fluidizing Media, 304SS

- 304 Stainless Steel Dust Cover

- Externally Mounted 230/460 Volts, 3 Phase, 60 Hz TENV Vibrator Motors with adjustable amplitude of vibration Installed

- All necessary Clamp Rings, High Temperature gaskets, etc., mounted on stainless steel vibration isolating springs and a carbon steel base and motor support table assembly

- Thermal couplers – Located at inlet and exhaust

- Spray nozzles plumbed to exterior with 1½”Ø TC Ferrule

- Insulated ducting between burner and dryer

- High-temperature flex hoses for connections

- 700K BTU Natural Gas Burner.

- Fan

-

Performance: 2,500 SCFM, 70°F, +10”WC

-

AMCA Arrangement 4 – Direct Drive

-

AMCA Rated for sound and air performance

-

10 Ga. Carbon Steel Construction with bolted access door & housing drain

-

Backward Inclined non-overloading wheel

-

Speed to be controlled by VFD

-

Fluid Bed Dryers vs. Belt Dryers

Fluid bed dryers force air upward from beneath the product, while belt dryers draw air from above the product by vacuum. When using vacuum, most of the air passes by the product in concentrated streams without contacting the product. This results in wet-spots, longer dry times, and less energy efficiency.

Fluid Bed Dryers vs. Rotary (Tumble) Dryers

Fluid bed dryers expose product to as much dry air as possible while using heat to accelerate the process. Rotary dryers, like clothes dryers, use a heat-centric method to evaporate the water and change the air to keep the moisture content from reaching saturation. Generally speaking, fluid bed dryers’ drawbacks are that they use more energy and greater homogeneity because they rely on airflow to provide lift to the product. But because herb is so light and because tumble dryers need the same homogeneity in this case (to prevent burning extract) these drawbacks do not apply.