Inspection Equipment

Choosing the right inspection equipment and using it properly is critical to the success of any process. Equipment can shear, employees can drop items, and suppliers can send contaminated inputs. We help protect your brand and customers by removing physically contaminated products from your line. Below you’ll find a far-from exhaustive list of popular equipment. If we seem like a fit but you don’t see the exact piece you’re looking for, fill out the form below; we can improve nearly any system.

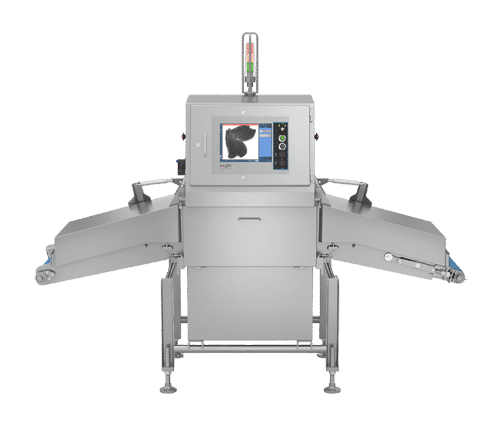

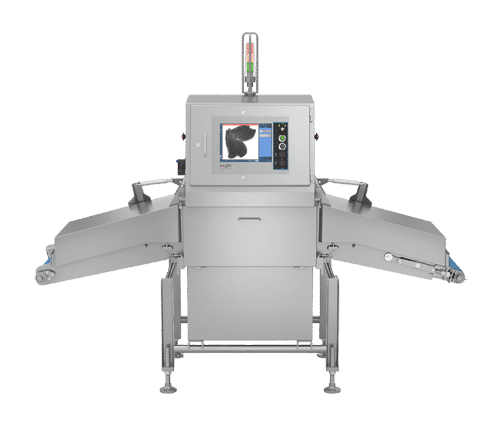

X-Ray Inspection

With continual advancements in the sector, x-ray is quickly becoming standard practice. Because data gathered from the images can be used to perform multiple quality analyses simultaneously, sometimes at over 1000 units/min. And with so much data being created in a single instance, numerous production insights can be gathered without having to interface several machines. The chief benefits are:

- Diverse detection capabilities (stones, glass, bone, dense plastic & metal)

- Customizable detection capabilities (because x-ray looks for varying densities, it can be set to look for situational abnormalities, such as air pockets in bread)

- Lower cost (when performing multiple functions)

- Additional quality checks (item count, fill level, fat analysis, package integrity, etc.)

- Packaging flexibility (metallic packaging, glass, cans, etc. do not interfere with detectability)

- Simple data collection

- Reduced bottlenecks

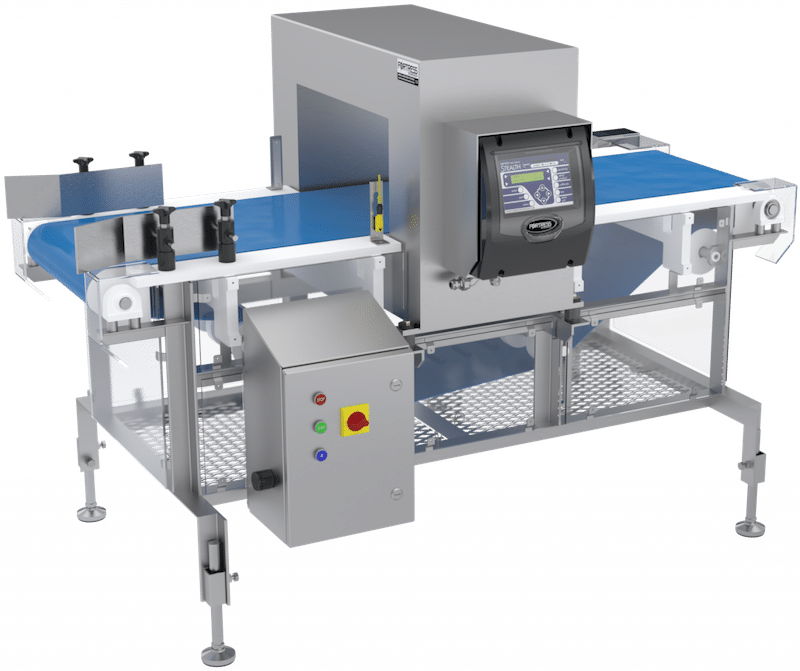

Metal Detection

Metal detection and x-ray are often seen as competing technologies because common contaminants are caught by both. Breadth-wise, however, this window is small and the ideal product line includes both. Metal detectors meet many buyers’ minimum requirements and are low-cost, but their detection range is narrow.

We carry multiple manufacturers and will help determine which models are best fits.

Metal detectors excel when:

Screening for very small, low-density metals or film (mylar)

The product is a powder

Metal detectors falter when:

Screening for stainless or non-metal contaminants

The product is a liquid

Product is frozen/thawing (will cause false positives)

Check-Weighing

Often combined with metal detectors to save space, checkweighers are single-function machines that ensure products aren’t over or under the acceptable weight range. They operate by taking actual weight of product as it passes over a moving belt, a method which comes with distinct pros and cons.

We carry multiple manufacturers and will help determine which models are best fits.

Advantages

Highly accurate readings for heavy items

Low-cost

Disadvantages

Less accurate readings for small items like food bars

Restricts line speed to ≈ 400-500 fpm (load cells must be cleared between each reading)