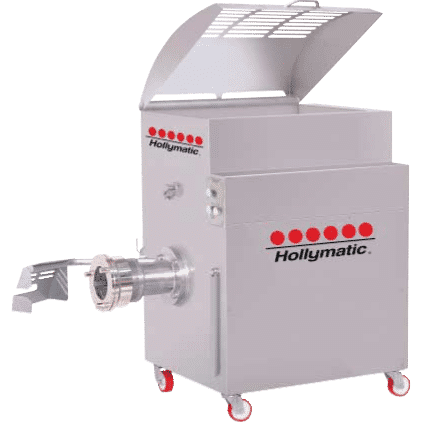

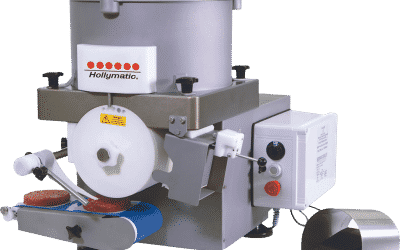

Capable of up to 146 lbs./min. with a 660 lb. hopper, the Commercial Mixer/Grinder efficiently homogenizes meat and plant products. It features thin paddles in the angle of ribbons, allowing it to strike a between the consistency of ribbon mixers with the throughput of paddle mixers, all while preserving the ability to mix forward and reverse. The Commercial Mixer/Grinder’s variable-speed motor and programmable timer also allow fast, slow, and automatic mixes. It is known for its ruggedness and reliability and is highly effective with any kind of meat fat to lean. Among other design considerations, the lid is equipped with a counterweight for ergonomic handling and an open-grid design for seasoning changes during operation.