Single vs. Dual-Stage Dryers

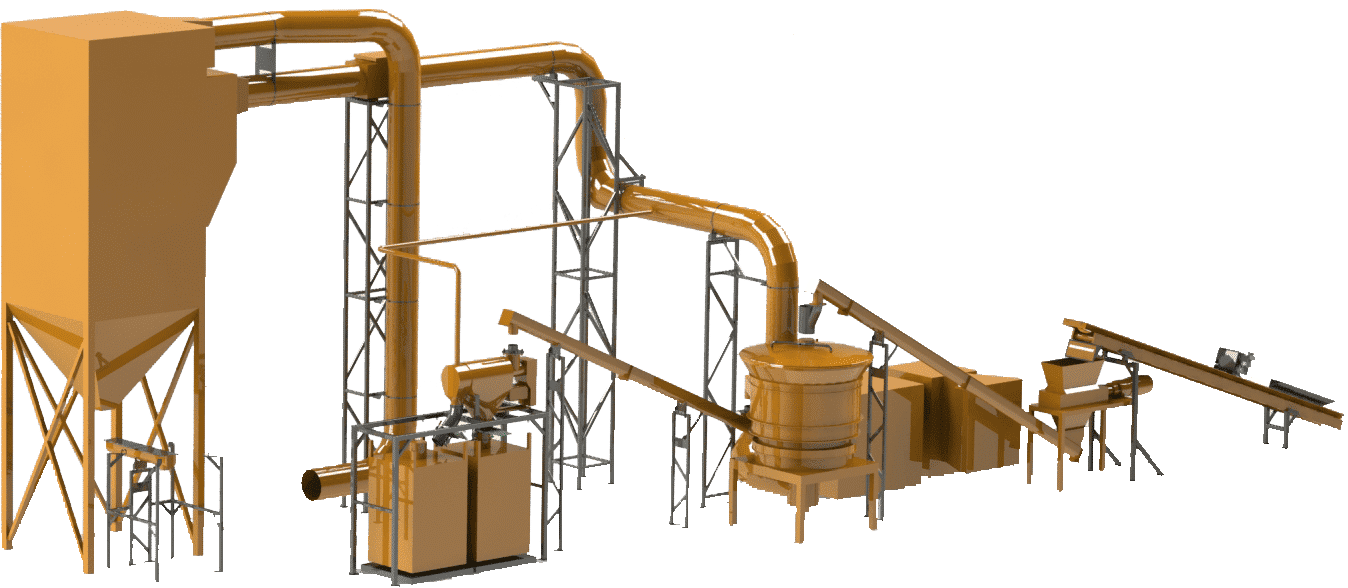

Single stage systems reach capacity at 1,000 lbs. of herbs per hour because all biomass is being dried at once. Dual stage systems can dry 3,500 lbs. per hour because higher temperatures can be applied to wetter product. Single stage systems can be scaled easily by adding the second phase when necessary.

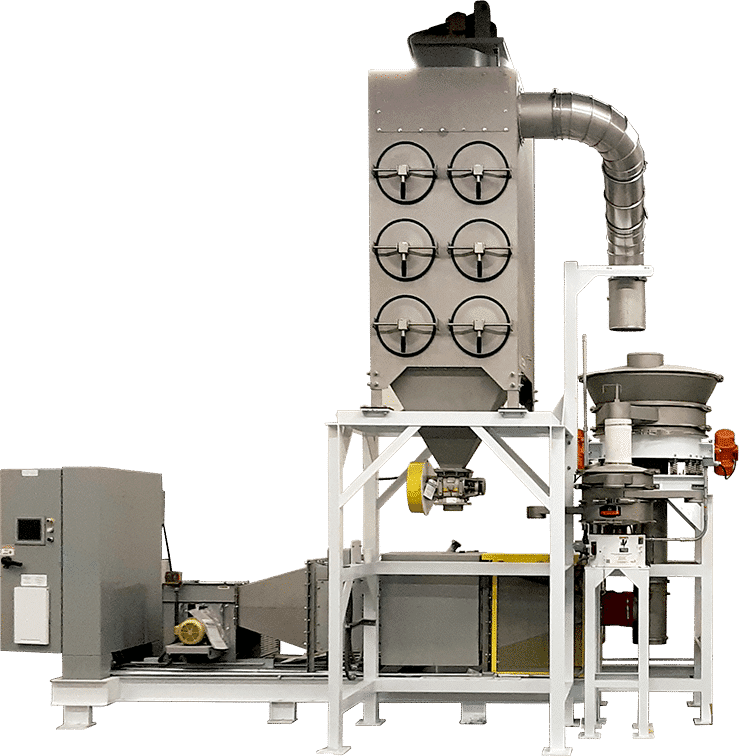

Both systems utilize circular fluid bed dryers. Fluid bed dryers are the best currently known method for drying all types of shredded herbs because they use less energy than belt dryers and protect more oil yields than rotary (drum) dryers. Learn more about the operating principle here. Circular fluid beds in particular are inherently preferable to rectangular designs because of their ability to dry evenly, clean more easily, and back-mix product.

Back-mixing is the process of continually mixing wet product back with the dry within a closed system. This allows the dry product to pull moisture from the wet, protecting it from burning and accelerating the process.

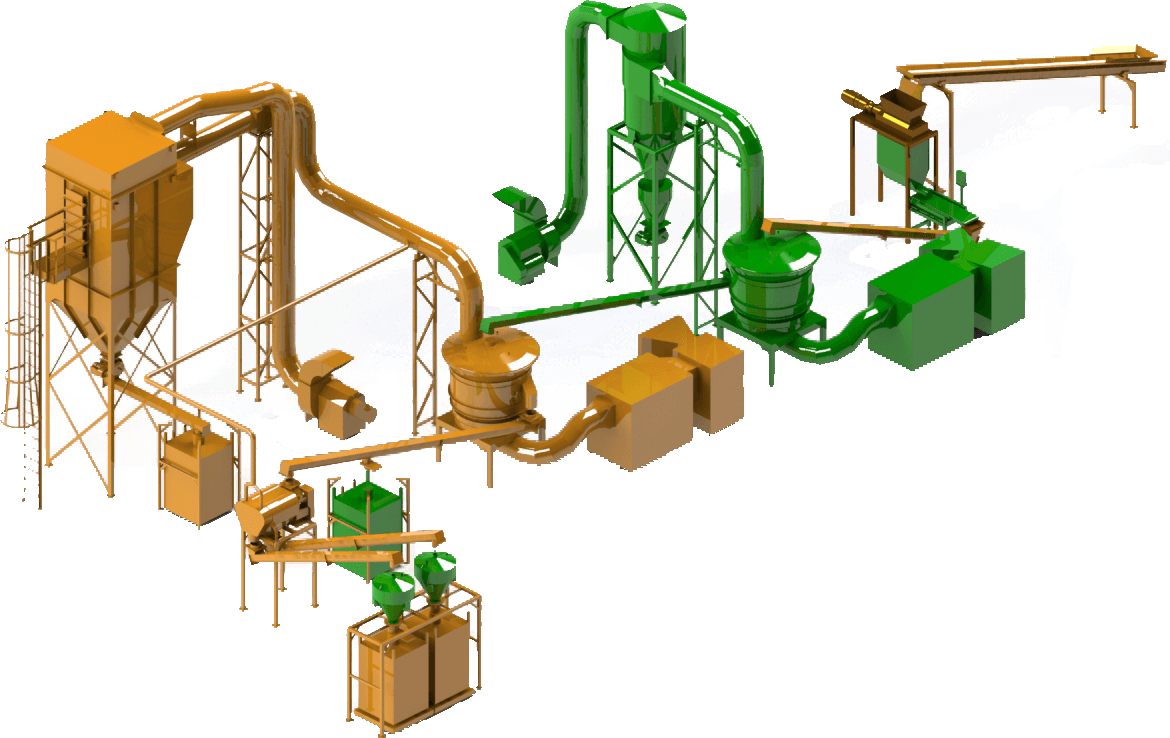

Dual Stage Dryers

Dual stage systems “flash” dry biomass in the first stage, separate stalks and stems from the leaves and bud, then dry only the premium product in the second stage. Drying in two stages does two things. First, it dramatically increases throughput because it can apply much higher temperatures to wet herbs and lower temperatures to dry.

Second, it reduces the overall amount of product that must be dried. Because it removes stalks and stems after the first stage, the overall burden on the dryers is reduced, and less energy is needed. This is especially helpful because the fibrous material is not just excess, it’s problematic. As a wood-like material, it releases moisture more slowly and disproportionately increases dry-time. In fact, the fibrous materials’ tendency to hold moisture is what allows us to remove it after the primary dryer because its difference in density causes it to behave differently in the separators.

Single Stage Dryers

Single stage dryers operate using the same base principles, but reach capacity at 1000 lbs/hr because all product must be dried together. Because the equipment being used is the same, this makes single-stage systems ideal for producers who don’t need high capacity drying at the moment, but would like the ability to scale up later without buying a new system. Second, because the system is more compact, it can be fit in tighter spaces, such as a trailer for mobile applications.

“Which system do I need?”

Choice comes down to throughput. A single stage dryer’s maximum capacity is 1000 lbs/hr, while a dual stage can do 8,000. And because the systems are identical except for the extra dryer and conveyor in the dual stage system, it’s not punishing to start with the small system and scale up as your process grows.

Contact Us

Reach out for a quote, more information, or just to talk about your process. We love discussing new ideas and want to hear about your application.