Bud Sorters

Sizes

Small Bud Sorter

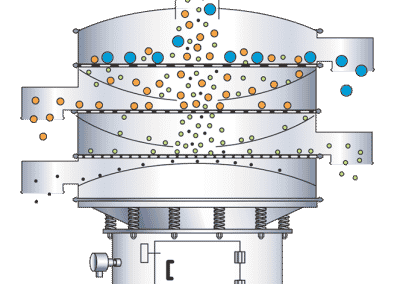

24” diameter 2-Deck High Efficiency Budsorter

One 4” high top spacing frame with a 6” diameter oversize discharge spout

One 4” high middle spacing frame with a 6” diameter product discharge spout

One 6” high discharge frame with a 6” diameter side discharge spout

Open Top (No Cover)

Four special metal screens and two wire mesh screens for installation of two at a time depending upon product being screened (mounted on standard tension rings with food grade gaskets).

Two (2) Quick Acting Clamp Ring Assemblies at screen sections

304 stainless steel product contact parts

Food Grade Glass bead Finish on frames

Epoxy coated carbon steel caster base and motor support table

½ HP, 230 volt, 3 phase, 1800 RPM, 60 HZ TENV motor

Motor Inverter will be included

Large Bud Sorter

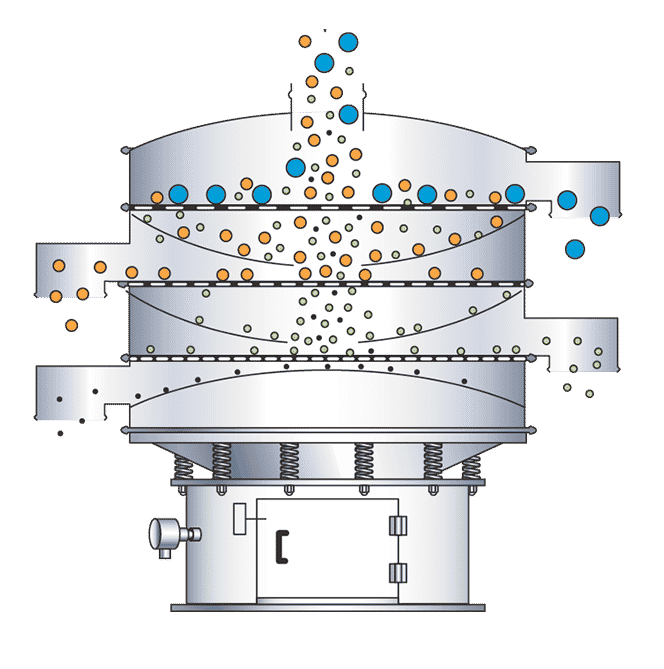

K40-2-SS, 2-deck Vibroscreen, 40” diameter 2-Deck Kason, High Efficiency Large Budsorter

One (1) 6” high top spacing frame with an 8” diameter oversize discharge spout

One (1) 6” high middle spacing frame with an 8” diameter product discharge spout

One (1) 6” high discharge frame with an 8” diameter side discharge spout

Open Top (No Cover)

Four (4) special metal screens and two (2) wire mesh screens for installation of (2) at a time depending upon product being screened (mounted on standard tension rings with food grade gaskets).

Two (2) Quick Acting Clamp Ring Assemblies at screen sections

304 stainless steel product contact parts

Food Grade Glass bead Finish on frames

Epoxy coated carbon steel caster base and motor support table

½ HP, 230 volt, 3 phase, 1800 RPM, 60 HZ TENV motor

Motor Inverter will be included

Options

Units are available in sizes up to 100″ inches in diameter and can accommodate most high-throughput applications

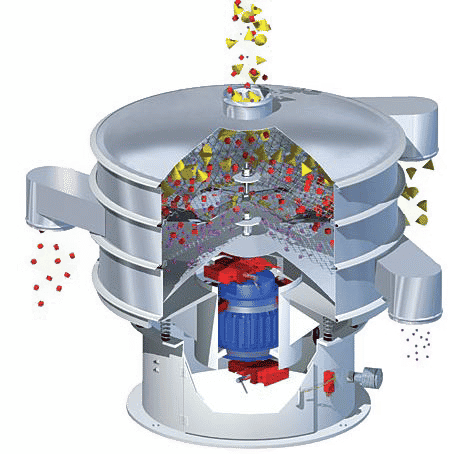

CIP (Clean-In-Place)

Our bud sorters feature leak-free nozzles positioned at all screen surfaces which blast typical sticking-points with solution and/or steam. Interlocking flanges bridge the gap between screen meshes and walls which exist in the other bud sorters. This minimizes ingress and streamlines cleaning.

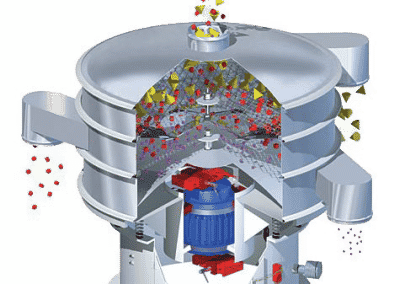

Variable Vibration Patterns

The unevenly-weighted gyro-motor is adjustable and capable of various oscillation patterns. This prevents milled buds from clumping or getting stuck and keeps them moving smoothly and efficiently.

Simple Screen Swapping

Various options are available for easy screen changes including fast-action band clamps connecting bed and lid, and air-lift devices which are helpful in larger models. Lids are not generally needed for sorting whole flower, however.

Batch-Sorting Operation

Optional hoppers allow product to be staged for batch operation, much like surge hoppers before Bulk Bag Loaders. Being attached to the screener, they vibrate upon operation, preventing product from bridging and aiding flow.

Quick-Change Lids

For the occasional process that requires a lid, there are a few clamshell lid options available. For smaller units, hinged lids can be fitted with quick-release band clamps with or without center-tensioning. Larger units can come equipped with air-lift devices for easy, single-person operation.