Process Design

Though technically a different discipline, process design is often fast enough to be considered part of engineering as a whole. At this step our Sales and Mechanical Engineers identify how to best achieve the end-goal in the most efficient and practical way possible. This includes:

Technology selection: Before they start looking at equipment, our engineers will use their existing understanding of the product, or that understood from testing unique products, to determine what available technologies are best fitting.

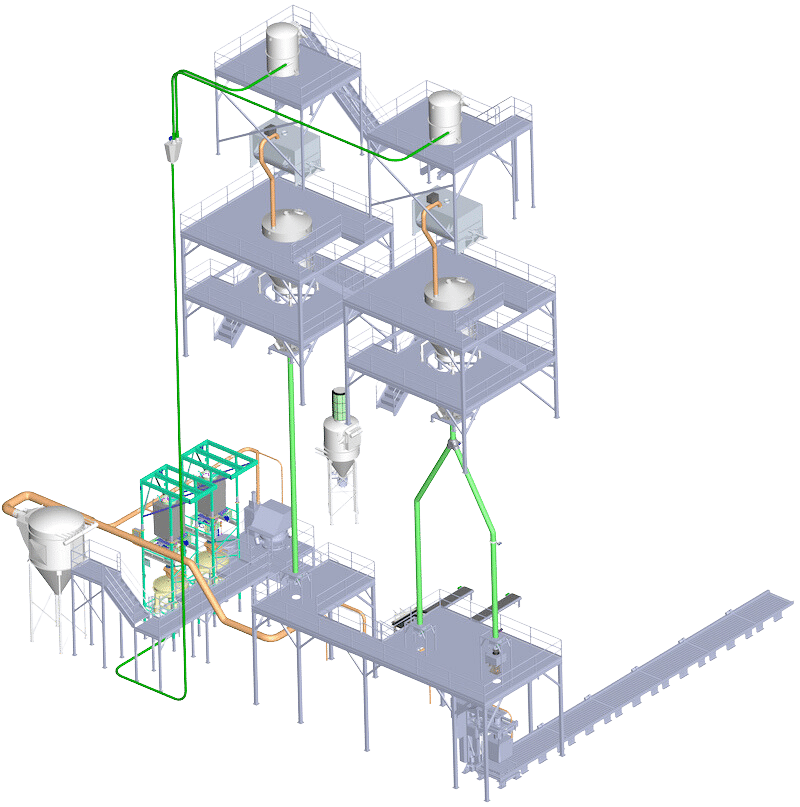

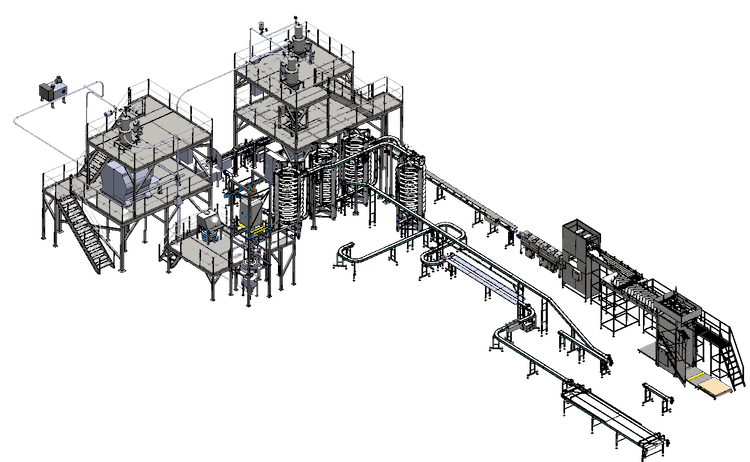

Process flow diagram: The next step is to create a process flow diagram that outlines the steps involved in the production process. This diagram helps identify potential bottlenecks and inefficiencies in the process and serves as a guide for designing the equipment layout.

Testing: Any outstanding questions at this step will be resolved with small-scale test-runs.

Equipment selection: Next, the make, model, and size of equipment must be determined, as well as the materials and resources needed to operate the equipment.

Process parameters: Temperature, pressure, and flow rates must be defined to ensure that the process operates efficiently and within the power threshold. These parameters may need to be adjusted as the process is scaled up or down.

Safety and environmental considerations: This includes identifying potential hazards and designing systems to prevent accidents and minimize environmental impact.

Structural design: After all the pieces have been selected and configurations decided on, we have to figure out how they are all going to fit together. This involves the industrial structures that will support and connect equipment such as custom transitions, mezzanines, and walkways for operators and maintenance.

Process Control

The next step is to simplify controls. Many individual pieces or sub groups of equipment will come with their own controls or ways to interface with complimentary equipment, and we look for opportunities to simplify them. We do this by removing those that will not be beneficial to the process and by combining others. For example, the heat increase in a fluid bed dryer may need to accompany an increase in blower power, so one could be made to trigger the other. We provide control system design and implementation to ensure your processes operate efficiently and safely.

To learn about what we can do for your project specifically, simply fill out the form below or give us a call!