Work Bins

Work bins can be as simple as a tote on wheels which allows personnel to work with product, or they can be larger pieces of equipment used to stage product in a continuous process, as shown in the gallery. They are typically made of durable materials like stainless steel, polyethylene, or aluminum, which are able to withstand the harsh conditions of food processing facilities. There are several different types of work bins, each designed for specific applications in food processing. Some of the most common work bins used in this industry include:

Ingredient Bins

Ingredient bins hold raw ingredients and are often used in the preparation stage. They are usually equipped with an airtight lid to prevent contamination and spillage, and some models even come with built-in scales for precise measurement.

Intermediate Bulk Containers (IBCs)

IBCs are large containers used to store and transport intermediate volumes of ingredients, finished products, or waste materials. They are commonly used in food processing plants to store bulk quantities of raw ingredients, as well as finished products that are waiting to be packaged.

Waste Bins

Waste bins are used to collect and store food waste, including scraps and trimmings generated during food processing. They are typically made of heavy-duty materials and come with locking lids to prevent contamination and discourage scavenging by animals.

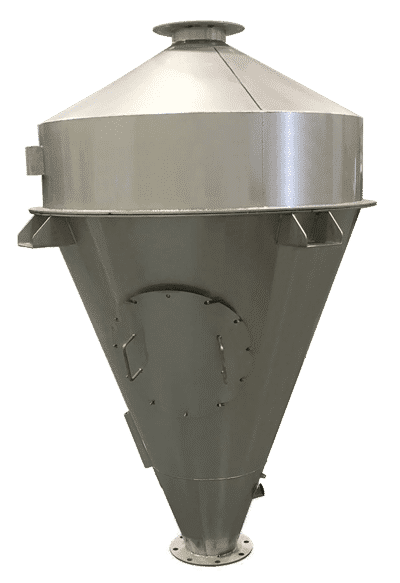

Bulk Storage Bins

These bins are used to store large quantities of raw materials, ingredients, or finished products. They are often used in conjunction with IBCs to maximize storage capacity and minimize waste.

Product Transport Bins

Product transport bins are used to transport finished food products from one area of the processing facility to another. They are typically made of lightweight materials, like plastic, and are equipped with casters for easy mobility.

Considerations

Regardless of the type of work bin you need, it is important to select one that is appropriate for the specific needs of your food processing facility. Some key factors to consider when selecting a work bin include:

- Material: The material used to make the bin should be appropriate for the type of food you are processing, as well as the conditions of your facility. For example, stainless steel is often preferred for use in meat processing facilities, while polyethylene is a popular choice for facilities that process fruits and vegetables.

- Capacity: The capacity of the bin should be appropriate for the volume of food you are processing. It is important to select a bin that is large enough to hold the necessary quantity of raw materials, ingredients, or finished products, but not so large that it becomes difficult to maneuver or store.

- Cleanability: Food processing facilities are required to maintain strict hygiene standards, so it is important to select a bin that is easy to clean and sanitize. This is particularly important for bins that will be used to store raw ingredients, as these materials are more susceptible to contamination.

- Durability: Work bins are subjected to a lot of wear and tear in food processing facilities, so it is important to select a bin that is durable and able to withstand harsh conditions. This includes factors like impact resistance, corrosion resistance, and weather resistance.

- Mobility: Work bins are often moved from one area of the processing facility to another, so it is important to select a bin that is easy to maneuver. This includes factors like weight, casters, and handle design.

Options

Most work bins can come with different options depending on your needs. This may include:

- Lids (with or without lift-assist)

- Dust collection ports/integration

- Flow control

- Dump lift

- Mix-assist

- Enclosed design

- Custom shapes

- Stainless construction

- Sanitary/Hygienic

To get the ideal work bin for your application built and integrated with your system, just give us a call or fill out the form below!