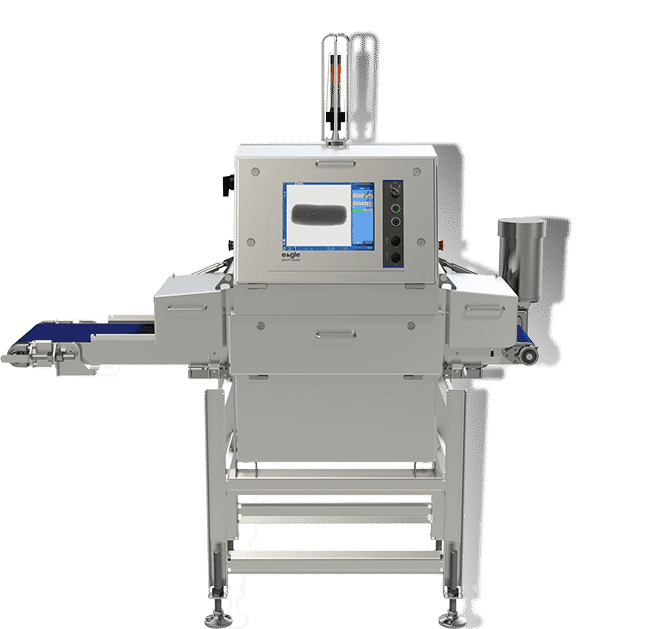

X-RAY INSPECTION SYSTEMS

Systems for all applications, industries and products.

Eagle Product Inspection’s wide portfolio of x-ray inspection systems are robust, reliable and constantly improving to get you the best fitting solution in the industry. ABM Equipment is dedicated to ensuring your system is the best, providing sales support, service and custom-solutions whenever needed.

SMALL PACKAGED PRODUCT X-RAY INSPECTION

Small packaged products range from an inch to several inches wide with heights of a fraction of an inch to several inches. These small sizes and frequently fast lines speeds pose unique inspection challenges. Be sure your x-ray system is designed to fit your product and your production line. From small blister packs, individual cereal bars, single-serve ice cream or small boxes, Eagle Product Inspection’s x-ray systems provide your facility with the most robust solution.

MEDIUM PACKAGED PRODUCT X-RAY INSPECTION

Medium packaged products with sizes from 17” wide to 8.5” tall are suited for x-ray inspection. Balancing machine size, line speeds and detection parameters can be tough. Trust ABM Equipment to assist with selecting the most fitting x-ray system for your food inspection application.

LARGE PACKAGED PRODUCT, CASE & MULTILANE X-RAY INSPECTION

Large bags, boxes, multi-packs and cases can be inspected via x-rays. Inspecting products up to 30” wide, with heights up to 22”, Eagle’s systems can perform all inspection and quality assurance tasks, even with multiple products inside. Large systems can be used for multilane inspection, which expands throughput, increases your production speed while reducing your operation costs.

BULK OR FREE FLOW X-RAY INSPECTION

Incoming raw material is often introduced in bulk, free flowing format. This is an ideal place for x-ray inspection to catch contaminants before they reach your downstream equipment or your final packaged product. Eagle offers curtain-less systems, designed for inspecting goods that rest directly on the belt with no system contact that could degrade the product. Whether your product is wet or dry, Eagle has developed an inspection solution and ABM stands ready to support it.

PIPELINE X-RAY INSPECTION

Inspection of pumped products like slurries, soups, ice cream, purees, baby food, ground meat, among others can be inspected directly in the pipeline. Eagle’s unique manifold inspection area and 3-way automatic reject valve ensures maximum inspection with minimal footprint and product loss. Catching contaminants before they reach a final packaged product, saving production and packaging costs.

TALL & RIGID UPRIGHT CONTAINER X-RAY INSPECTION

Jars, bottles, cans and other tall, rigid upright containers are capable of being inspected via x-rays. Maintaining the upright product orientation in your production line can be critical. One broken jar or smashed container can stop production and cost time and money for cleanup. Shouldn’t your x-ray food inspection equipment match production requirements? Eagle’s line of tall and upright container x-ray inspection machines offer single, dual and quadview technology to increase the probability of detecting contaminants in your product. Finding contaminants such as glass in glass, metal in metal as well as stones, calcified bones, plastics and rubber compounds.

MEAT X-RAY INSPECTION & FAT ANALYSIS

When margins are slim – every kilo counts. Eagle Product Inspection’s range of meat inspection systems is far reaching. Specializing in bulk and carton inspection for contaminants such as buck shot, knife tips and bone, alongside fat analysis for chemical lean. Eagle’s FA and RMI systems were designed and constructed specifically for the meat industry. Built to withstand harsh washdown environments and boasting the most comprehensive contaminant and fat analysis systems, Eagle’s x-ray machines are top of the line.