Circular Fluid Bed Dryers

Circular fluid bed systems are widely used in the chemical, pharmaceutical, and food industries for any application where the surface area of a product needs to be maximized for airflow. These applications include drying, cooling, moisturizing, and sometimes granulation. These systems provide several advantages over traditional (rectangular) fluid bed systems, including tightened control over the process, reduced operational costs, increased productivity, and easier cleaning processes.

Operating Principle

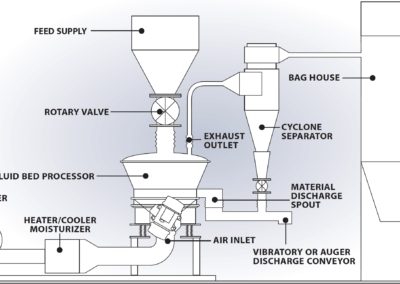

Circular fluid bed systems work on the principle of fluidization, where air is passed through a bed of particles on a vibrating surface to create a fluid-like state. This allows the particles to move freely and allows for even heating, cooling, and mixing of the material. In a circular fluid bed system, the air and product are moved in a continuous, circular motion. This keeps product from getting stuck on the edges and applies desired effects more uniformly.

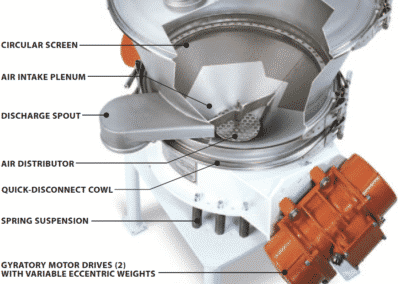

Design Features

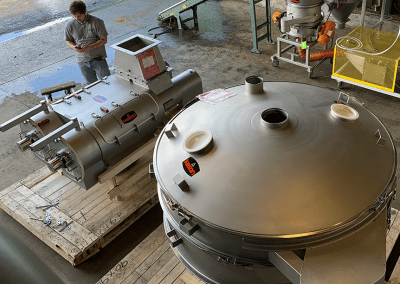

Circular fluid bed systems are typically composed of several key components, including a circular fluidizing chamber, a gas inlet, a gas outlet, and a control system. The circular chamber is typically constructed of stainless steel or other high-grade materials and is designed to provide even fluidization of the material. The gas inlet and outlet provide a means for controlling the flow of air through the system, and the control system allows for precise control of the process parameters. These fluid beds are available in carbon or stainless as well as an optional gap-free design for fluid-laden material. And because there are no edges for product to accumulate in, it can be cleaned extremely easily.

Applications

Circular fluid bed systems are widely used in various industrial processes, including drying, cooling, and granulation. These systems are particularly useful in applications where the material being processed is sensitive to heat or where uniform heating and cooling are important. Additionally, circular fluid bed systems are commonly used in processes where the final product size and shape must be controlled, such as in the manufacture of pharmaceuticals and food products.

Energy Efficient

Fluid beds are among the most efficient drying methods because they rely on an air-first, heat-second strategy, as opposed to tumbler dryers, for example. And among fluid beds, circular models are, depending on the application, inherently more efficient than rectangular. Generally they require less airflow and less energy spent on agitation.

Why Choose ABM?

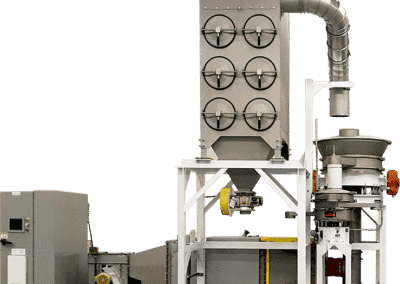

With hundreds of unique applications under our belt, we are intimately familiar with different materials and how they like to be handled and dried. By purchasing from a firm with legitimate fabrication capabilities and experience, you can bridge the gap between sales of existing equipment and what will perform highly in your line.

- Customizations: Our team of experts will work with you to understand your specific process requirements and modify an existing model of fluid bed dryer or design an entirely new one that meets those needs. Any machine alterations needed will ensure that the dryer is optimized for your particular process.

- Integration: We can install the fluid bed dryer into your existing process line, ensuring seamless integration and minimizing downtime. Our team will work with you to understand the specific requirements of your process line and design the dryer to meet those needs.

- Expert Service: Our technicians and engineers who designed your solution are available to provide ongoing service and support for your fluid bed dryer. This includes regular maintenance, troubleshooting, and repairs, ensuring that the dryer operates at optimal efficiency and reducing the risk of downtime.

- Proven Results: With years of experience in the industry, we have a proven track record of delivering high-quality solutions that meet the needs of our customers. Our fluid bed dryers are designed and manufactured to the highest standards, ensuring reliability and longevity.

- Cost-Effective: Processing equipment is expensive, and so are mistakes. By allowing us to customize, integrate, and service your fluid bed dryer, you can save money and reduce operational costs. Our team will work with you to understand your budget and design a cost-effective solution that meets your needs.

- Ongoing Support: Our commitment to customer satisfaction doesn’t end when your fluid bed dryer is installed. We are always available to provide ongoing support and service, ensuring that your dryer operates at peak performance for years to come. We hope you’ll never need it, but our lines are open 24/7.

To learn more about FBDs or get a quote for your process, give us a call or fill out the form below!