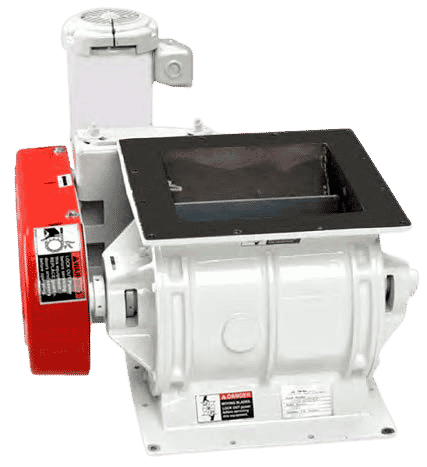

Rotary Valves

Rotary valves are flow control devices commonly used in the conveyance of powders, granules, and other bulk materials in a material handling system. They can be used simply for flow control with standard belt conveyors, for example, but they are critical for pneumatic conveyance systems to prevent the negative pressure caused by airflow to suck product out uncontrollably. Rotary valves are also often used in the food, chemical, and pharmaceutical industries to assist the flow of difficult and bridging material.

Operating Principle

The basic design of a rotary valve consists of a rotor, or rotating shaft, that is fitted with vanes or blades. As the rotor turns, the vanes or blades scoop up the material and guide it through the valve. The speed and direction of the rotor determine the flow rate of the material through the valve. By adjusting the speed and direction of the rotor, the flow rate can be precisely controlled, allowing for accurate metering of the material.

Advantages

One of the main advantages of rotary valves is their ability to handle a wide range of materials, including powders, granules, and pellets. They can also handle materials that are abrasive, hygroscopic, or have a tendency to pack or bridge. Rotary valves are also capable of handling high flow rates and are able to maintain a consistent flow rate even when the inlet pressure or temperature fluctuates.

Another advantage of rotary valves is their ability to be used in a variety of applications. They can be used as a feeder, a metering device, or as a shut-off valve. They can also be used in conjunction with other equipment, such as a conveyor belt or pneumatic transport system, to create a complete process system.

Rotary valves are also relatively easy to maintain and have a long service life. The vanes or blades on the rotor can be easily replaced if they become worn or damaged, and the seals on the valve can be easily replaced if they begin to leak. Additionally, the valve can be disassembled and cleaned if it becomes clogged with material.

Types of Rotary Valves

There are different types of rotary valves available, such as diverter valves, blow-through valves, and sanitary valves. Diverter valves are used to divert the flow of material from one outlet to another, while blow-through valves are used to blow air or other gases through the material to prevent it from bridging or packing. Sanitary valves are designed to meet the stringent sanitation requirements of the food, pharmaceutical and other industries.

To find out which rotary valve we carry is best for your system, or to get service for a malfunctioning unit from another manufacturer, give us a call or fill out the form below. We’d love to help.