Distillery & Brewery Dust Collection Systems

Low-maintenance, Long-Lasting, set-and-forget

The rapid rise in local regulations concerning dust collection in breweries has made it necessary for more brewers and distillers to implement effective dust collection systems. ABM ensures your system meets your production and city standards with system design, integration, and service.

Reliable

Systems made of US & European components you can count on for decades to come

Custom-Configured

Designed for the local climate, seismic area, and municipal codes to keep everyone happy

Low-Maintenance

Self-cleaning systems you can forget about for months or years at a time depending on size

Effective

Expertly-integrated systems that prevent pests, reduce cleanup, protect lungs, and avoid slips.

Why The Push For Dust Collection in Breweries & Distilleries?

When something mildly combustible—like grain—is milled, the surface area of the material is increased exponentially, making it explosive at a certain point. The risk is greater for distillers than brewers because they use hammer mills rather than roller mills, but there have been incidents in breweries as well. Naturally this has caused some legislators to overreact both in cities and nationally, as reflected in the updated National Fire Prevention Act (NFPA 68). But it’s not all bad, because dust collection provides a number of benefits to health, operational efficiency, and pest prevention.

Dust Collector Options

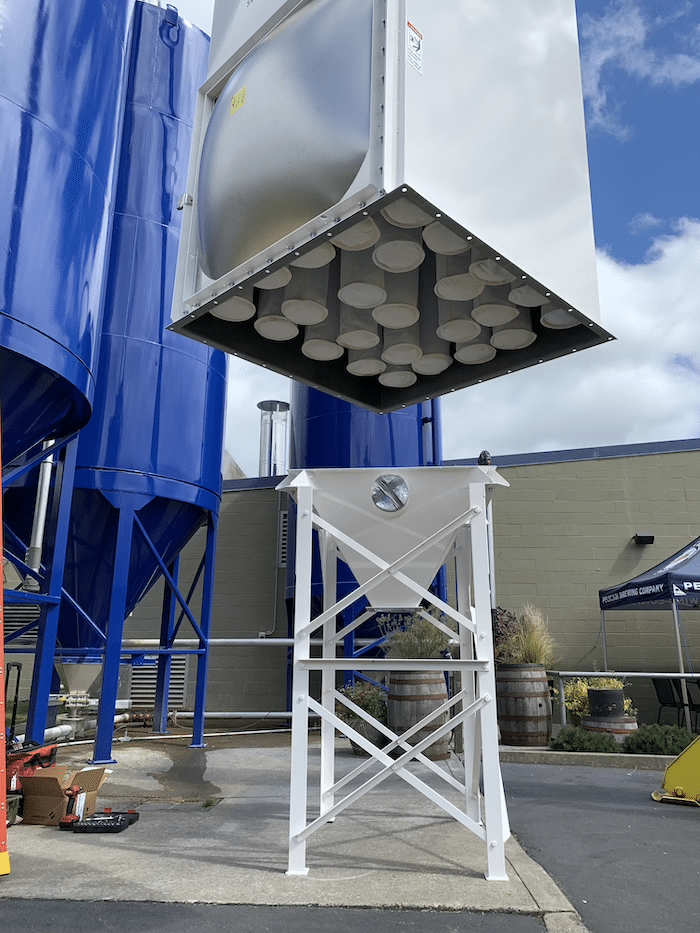

Though we offer every type of system, baghouses are the preferred method for breweries because of their lower cost and maintenance requirements for the application. A cartridge would be easier to change, but would clog frequently enough that it would be annoying. The kinds we install for breweries are self-cleaning and can go for years without a bag change so you can truly set it and forget it. Among the dust collectors appropriate for breweries, the options are:

-

Bucket-style discharge

-

Pulse jet timer for bag cleaning

-

Differential pressure magnehelic gauge kit

-

Painted carbon steel or stainless steel

-

Hinged door with T-handle (toolless) entry

-

High or low-entry inlet

-

Explosion mitigation panels

Dust Collection Implementation

There are two primary methods for dust collection in breweries:

Whole-Room Negative Pressure

Suitable for breweries with contained mill rooms. This method involves installing vents in the ceiling to draw air off the entire room, maintaining a controlled and safe atmosphere. This method is slightly cheaper and more effective, but the difference isn’t so great that it should have a great impact on choice of space.

Dust Ports on Equipment

For breweries preferring not to alter the room’s air, or whose grain equipment is scattered through the space, our equipment is designed with dust ports that connect to an external dust collector. We can then run ducting to each port, pulling vacuum on each piece of equipment.

Hybrid

If you have a room big enough for most of your grain equipment but not all, it’s easy to draw most of the air from the mill room and run small ducting to the equipment outside of it. And whether all your equipment is outside or inside of a mill room, drawing air from both the equipment and the room will improve your experience.

Benefits of Dust Collection In Breweries & Distilleries

Implementing a dust collection system in your brewery or distillery can offer numerous advantages:

Explosion Prevention: Significantly reduces the risk of grain dust explosions.

Health and Safety: Protects employees from respiratory issues and allergic reactions to grain dust.

Pest Prevention: Lowers the chances of pest infestations by removing dust that can serve as a food source.

Operational Efficiency: Dramatically reduces the need for cleanup.

Compliance: Ensures your brewery meets local and national safety standards, avoiding potential fines and shutdowns.

Why ABM?

Efficiency

A “one-stop-shop”, ABM designs, supplies, integrates, and maintains your system when necessary. By keeping the whole project under one roof, we can provide the best value for the money with as little mental work on your part as possible.

Experience

With over 40 years of experience in dust collection for various industries including food processing plants, ABM Equipment is able to to deliver the best solution from day one. Our history with flour plants and other facilities has given us insight into the best practices for managing dust without reinventing the wheel.

ABM Equipment offers customizable brewery dust collection systems tailored to your specific needs, whether you’re in the planning stages or looking to upgrade your current dust management system. Our solutions range from low-cost baghouses, ideal for most brewery applications, to high-hygiene cartridge units for specialized needs.