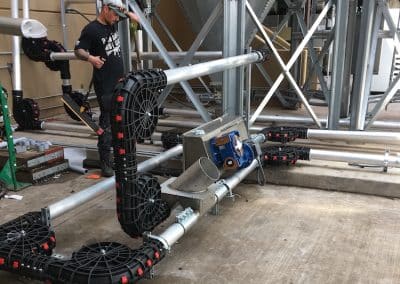

Tubular Drag Conveyors

Tubular drag conveyors are great for most non-abraisive, free-flowing products including powders, pellets, and granules. Capacities can vary depending on the configuration and product, but as a reference, tubular drag conveyors reach capacity with milled grain at 2,000 ft. through 24 elbows and conveying at a rate of about 300 pounds per hour.

Operating Principle

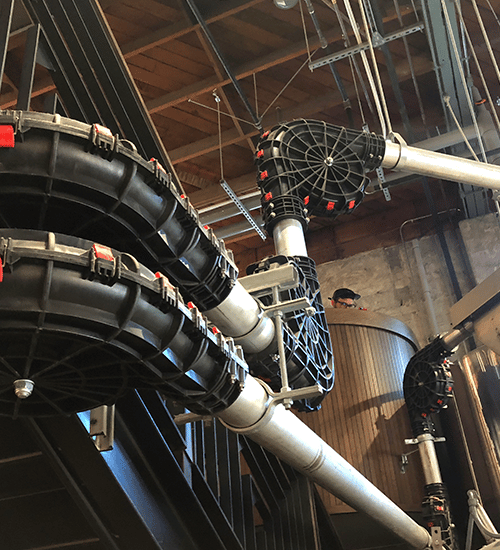

The conveyor chain, which is made up of a series of flights of poly discs, is positioned inside the tube or pipe and is driven by a motor at one end of the conveyor. As the chain moves along the length of the tube, the flights on the chain catch the material and move it along the conveyor. The material is conveyed gently and efficiently through the tube or pipe, without any spills or material breakage. Tubular drag relies on a degree of bridging in the product to prevent rollback and usually there is almost none.

Tubular drag conveyors are great for most non-abraisive, free-flowing products including powders, pellets, and granules. Capacities can vary depending on the configuration and product, but as a reference, tubular drag conveyors reach capacity with milled grain at 2,000 ft. through 24 elbows and conveying at a rate of about 300 pounds per hour.

Benefits

Tubular drag conveyors are much more versatile than augers, able to accommodate multiple inputs and outlets and navigate restrictive requirements. The enclosed design of the tube or pipe prevents contamination of the material by dust, dirt, or other external elements, and prevents spills and waste.

Another key advantage of our tubular drag conveyance systems is their low-maintenance requirements. With very little friction between the pucks and the tube, they last much longer than the augers they typically replace.

Tubular drag is also highly efficient, able to loop back through inputs and outputs with a single drive.

Though it us most commonly deployed as carbon, tubular drag is available in stainless and CIP configurations for sanitary applications.

Tubular drag conveyors’ weakness is that they are not suitable for many soft or delicate products, and although the tubing is available in metal, they should not be used with high-temp products.

Chain vs Cable Systems

Tubular drag can come in either chain or cable configurations. The pros and cons are similar but may make the choice easier for your application.

Cable Systems

Pros

A faulty cable strand will not cause system to fail

Higher degree of cleanliness at outset

Cons

Likely to wind up over time

Critical strand failure on new cable can go unnoticed

Cable coating wears down over time and impacts cleanliness

Aged cables can fray and pieces can splinter into product

Chain Systems

Pros

Very strong

Longer-lasting

Maintain their lower level of cleanliness longer

Faulty links will be noticed immediately

Cons

Lower degree of cleanliness at outset

Chain friction can produce nanoparticles

Fautly links, though extremely rare, will cause the system to stop

Why ABM?

ABM is more than just a connection to OEMs. With over 20 years of experience in the industry, we have built a reputation for providing high-quality, reliable, and effective conveying solutions to a wide range of industries.

With a team of experienced engineers and technicians, we provide customized solutions to meet the specific needs of our customers. We work closely with you to understand your requirements and recommend the most suitable conveyance configuration for your application.

We offer ongoing service and maintenance for our packaging systems to ensure they continue to operate at optimal performance. Our technicians are knowledgeable and experienced, and are available to provide on-site maintenance, repair and support services.

Whether you are looking for a single piece or a cohesive system, ABM Equipment can help scale and automate your process. Contact us below to learn more about our services and how we can help you achieve your production goals.