Vibratory Feeders

| Best For |

Non-sticky, free-flowing products (powders, granules, chips, flakes & fibers), abrasive materials, and applications where the destination vessel is not pressurized. |

| Made In | USA |

Models

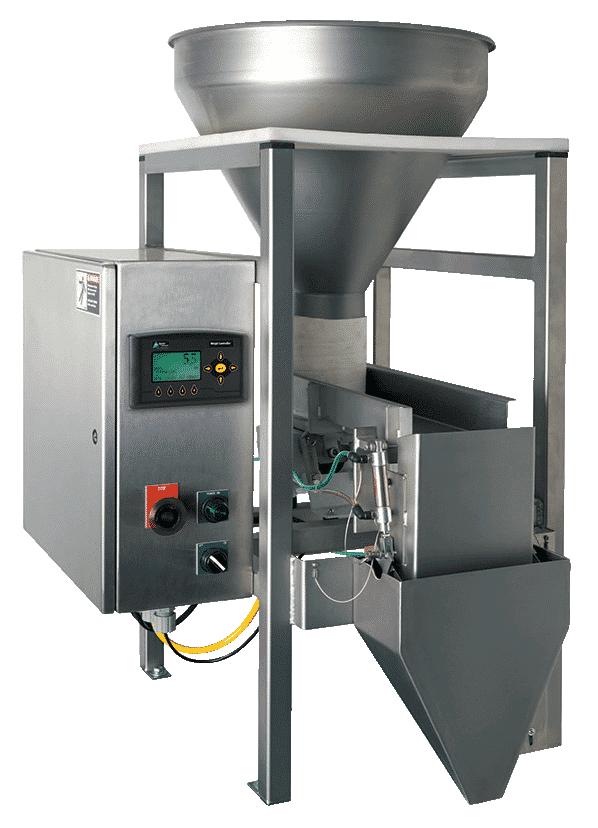

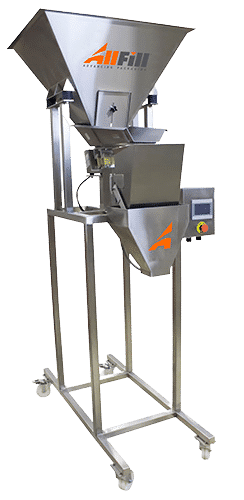

Small Feeders (2 oz. – 5 lb. increments)

Practical for automated or semi-auto processes with operators placing and removing containers, the small vibratory feeders fill a small bucket which sits on load cells and dispenses into the package or process when it reaches the target weight.

Features:

Weigh speed: ≤12/min

Accuracy: ± 0.4 – 1%

Electrical: Standard (120 V, 5 a)

Air: 90 PSI, 1 cfm

Dimensions: 20” W x 46.6” H x 30.6” L

Removable hopper

Toolless disassembly

Timed discharge to mitigate spills

Options:

Variable flow

Bulk accumulation (for 5 lb.)

Auto-tare

Conical hopper (for improved flow)

Sanitary Design

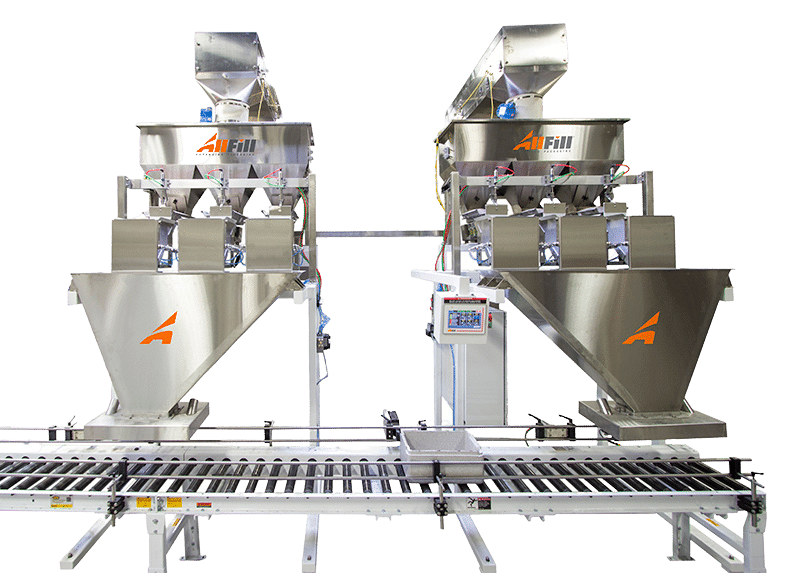

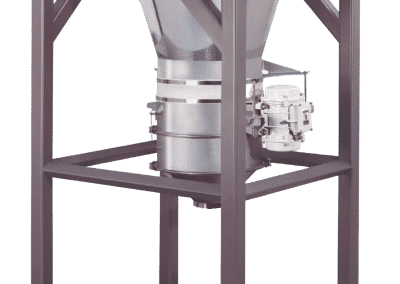

Mid-Range Feeders (2 – 25 lbs.)

Great for automated or semi-auto processes with operators placing and removing containers, the intermediary vibratory feeders fill a small bucket which sits on load cells and dispenses into the process or package when it reaches the target weight.

Features:

Weigh speed: ≤12/min

Accuracy: ± 0.5%

Electrical: Standard (120 V, 5 amp)

Air: 90 PSI, 1 cfm

Dimensions: 40.87” W x 58-60” H (adjustable) x 38.63” L

NEMA 12 Enclosure

Options:

Variable flow speed

Dual set-point

Bulk accumulation (for 12 lb increments)

Toolless disassembly

Auto-tare

Wahdown/sanitary configurations

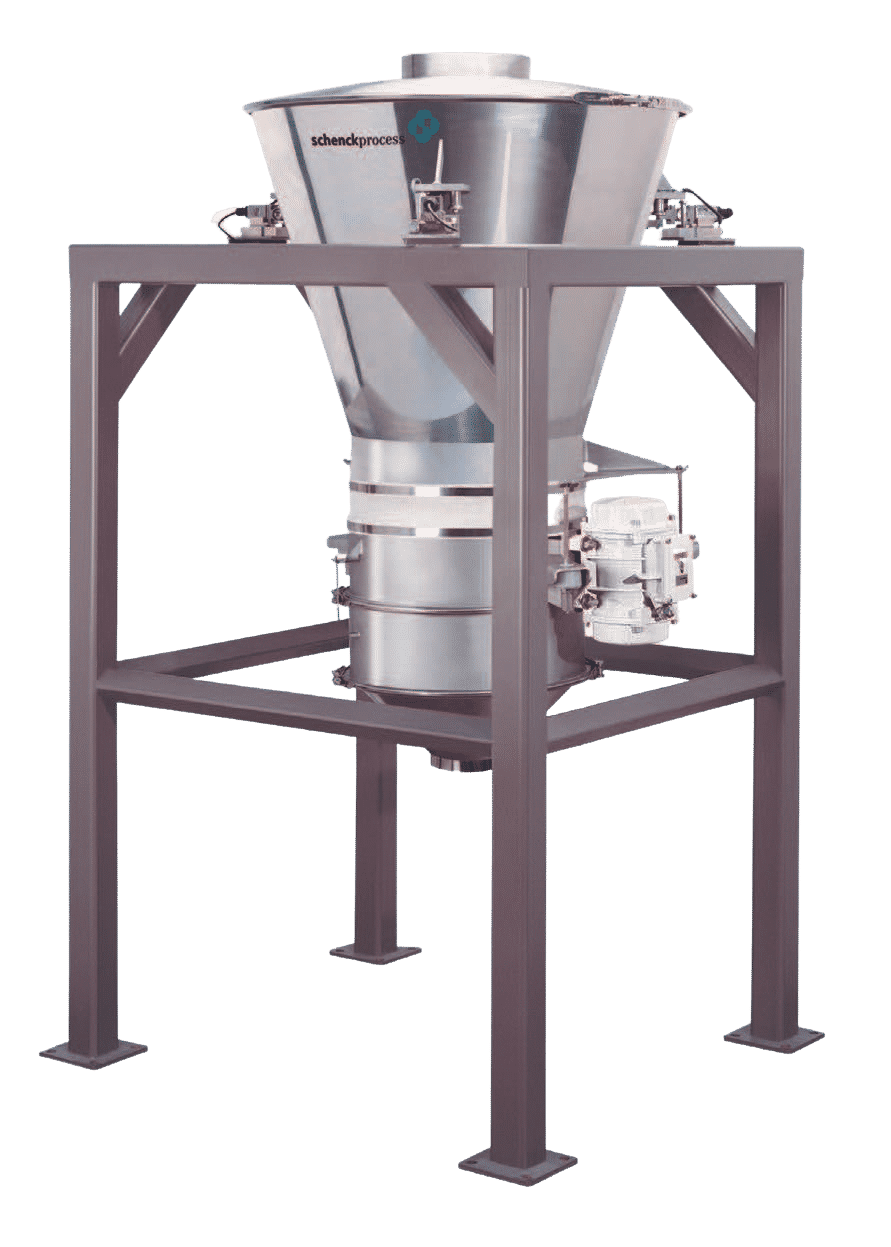

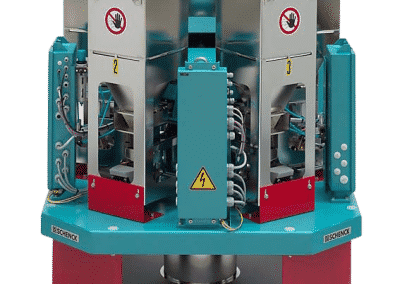

Large Feeders (22 – 341ft³/hr)

Available in a wide range of throughputs, the large vibratory feeder can be configured to feed up to 341 cu ft/hr. With numerous design considerations for easy operation and sanitation, it is FDA and USDA approved, and used in both industrial and pharmaceutical applications alike. The non-reactive contact materials, high-grade steel (polished to 32 micro-inches), and crevice-free design protect product and keep out extraneous materials and moisture.

Features:

Accuracy: To spec

Motor: 230/460 VAC, 3 HP, 60 Hz

304 Stainless hopper

2-piece tray allows quick disassembly for cleaning

Sanitary design

– Domed lid

– Crevice-free contact surfaces

Options

Volumetric configuration

3-A Sanitary configuration

316 SS electropolished finish

Hopper Motors (IP66 wash down)

– 0.17 HP (6 & 12”)

– 0.52 HP (18 & 24”)

Vibratory feeders use vibration to fluidize free-flowing product, controlling its flow into either a process or a weigh bucket for portioning and packaging. Whereas screw feeders can move product up inclines and handle liquids and viscous slurries, vibratory feeders are better for irregular product and those that would damage or be damaged by feed screws. If your product fits in neither or both categories, reach out and we’ll identify the best solution.

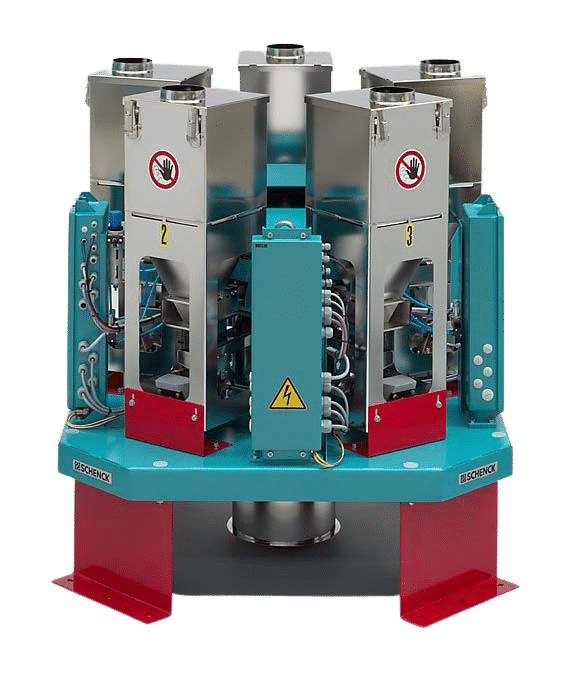

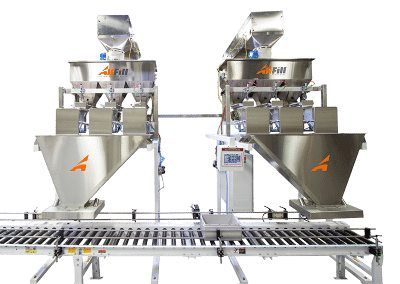

Multi-Head Feeders

Multi-head vibratory feeders can be configured in a number of ways depending on the application. Each bucket can dispense directly into bags in a roundabout, be fed into a common hopper for gentle but rapid filling of in-line containers, or buckets can be placed in a cascading fashion. This allows buckets to double-check weights when dispensing small amounts of product in large increments. For example, if placing 10 gummies in a bag, one gummy too much or too little is 10% off, which is unacceptable.

Weighing increments: 1 – 75 lbs.

Features

Accuracy: ± 0.25 to 1%

Electrical: 102 V, 1 Phase, 60 HZ (options available)

Air: 60 PSI, 10 cfm

Options

Partitioned hopper for ingredient mixing

Nylon coating

Dimpled contact surfaces

Washdown configurations

Electric feed gate

Vibratory vs. Screw Feeders

Vibratory feeders are best for higher volume applications, delicate materials, and those with irregular particle sizes. They are often also easier to maintain because the parts are more accessible.

Screw feeders are able to handle runnier and stickier products, and are also able to dispense into vessels with pressure or high airflow. Sometimes there is no way around it, but they are not ideal for abraisive materials because the feed screws will wear unnecessarily.

Have a feeding application? Tell us about your project in the form below and let us quote your project!