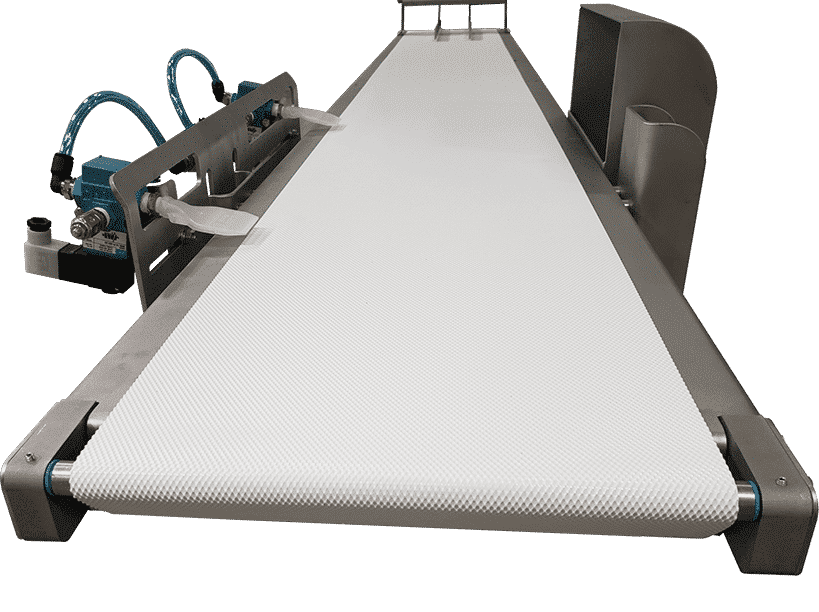

Flat Belt Conveyors

Flat belt conveyors are the simplest and most common of conveying methods but are used for relatively lower capacity and speed applications compared to other methods. They can be used on slopes up to a maximum of 20° but use on slopes is rarely advisable. Flat belt conveyors are available in endless configurations, which we source or construct, usually depending on where it’s cheaper to ship from. We provide all services required for the installation and maintenance of virtually any flat belt conveyors.

Drive Methods

Traditional Belt Conveyors (ie. friction/negative drive)

When most people think of belt conveyors they think of belt tensioned around drives and being moved by the friction between the belt and drive. This is the most common method but requires more maintenance and drive adjustment in heavy applications. This is because more weight means not only more strain on the belt, but more slippage and wear. Additionally, they take more work to clean in sanitary applications because tension has to be removed in order to clean under the belt. But for most applications the negative drive belt remains the most practical and cost-effective option.

Positive Drive Conveyors

Positive drive conveyors use direct force instead of friction to move belt; this is achieved with recessed notches in the belt and geared drives with cogs (or visa-versa). These cogs fit into the notched belt (or visa-versa) which is moved directly, without any slippage. Because this method does not require tension to operate, it doesn’t need to be adjusted as much and is easier to clean. An example is shown here, courtesy of Intralox.

Drive placement

Drives are placed at the head (discharge) whenever possible because that’s where they perform best. When driven at the tail, there is no direct force on the load-bearing side of the belt (you can’t convey boxes by pushing a rope they’re sitting on). The belt must be pulled, which means pulling the belt around the opposite side, inflicting double the wear because it’s being tensioned around two points.

There are, however, special applications where placing the drive at the tail will provide more value than it consumes. For example, if the belt is discharging into a sanitary environment, close proximity of gearboxes and non-sanitary components is not acceptable. It could also simply make more sense service-wise if the drive is inaccessible at the head.

Drives can also be placed in the middle of the belt in special circumstances, such as when you’re loading the belt in the center and swapping the conveyance direction to discharge at alternating sides.

Materials

Conveyor belts can be made of various materials depending on the product, including inter-linked plastic which can shift and convey about corners. Material type largely depends on product temperature, mass, abrasiveness, and sanitation requirements.

Most Common Material and Application Pairings

Metal – Filter, heat, bakery, de-oiling, de-watering

Rubber – (Most common type of belt), aggregate, packaging, most non-food applications

Plastic – Food

Fabric – Specialty applications (mostly obsolete)

Neoprene – Packaging (because of its oil-resistant nature)

Poly Belt – Packaging (because of its oil-resistant nature)

Linked plastic (modular) – When practical because of its affordability, (does not bode well in high-impact applications

Pulley types

Drive pulleys can be crowned (wider in the center) to help keep the belt from walking, and standard pulleys can be placed in a number of configurations to handle slack. Crowned pulleys are most common for receiving raw product like beets & potatoes and are not necessary in positive drive applications.

Frame configurations

Conveyor belts may have a number of different frame configurations depending on what the application yields itself to. But whether you can use hollow support points depends on regulations. (FDA allows hollow support points, USDA does not.)

Beds

The beds for conveyors are usually flat and only meant to support the belt, but they can also be fitted with sidewalls to help contain and protect product. But because of the contact between side-walls and product, trough belt conveyors are used for particularly abraisive or delicate materials or foods. Trough belt conveyors are also preferred over walled flat conveyors in sanitary applications because they’re much easier to clean.

Reject Systems

Flat-belts can be fitted with a huge variety of rejects, all of which we build for the application. The techniques used could include diverters, push-arms (pneumatic or electric), drop-panels, air blast, magnets, and others. In bulk applications where rejection of good product with the bad cannot be avoided, accuracy must be maximized to reduce the effect.

From conveyor repairs to complete system design and integration, we help move bulk dry goods efficiently. Whether it’s food, pharma, or industrial, there is a best method for moving every product and we deliver the appropriate level of speed and gentleness, all backed by 24/7 service.

Get In Touch

Tell us about your project and we’ll provide a quote, go over your options, or simply point you in the right direction.

"*" indicates required fields

Industries

Warehousing & Distribution

Manufacturing

Aerospace

Automotive

Parcel Handling

Cabinetry & Furniture

Aggregate

Agriculture

Baby food

Bakery

Beverage

Building materials

Cannabis

Cereal & Grains

Chemicals

Chemicals & Fertilizer

Confectionery

Dairy

Distillery

Electronics

Energy

Food

Fruit & Vegetables

Grocery / Point of Sale

Hemp

Laboratory

Livestock

Manufacturing

Meat

Medical / Veterinary

Nutraceuticals / Supplements

Nuts

Packaging

Personal Care

Pet Food

Pharmaceutical

Plastics

Poultry

Ready Meals

Recycling

Red Meat

Seafood

Shipping

Snackfood

Spices, Syrups & Sauces

Tobacco

Warehousing, Transport, & Logistics

Waste

More Conveyors

Screw Conveyors

Screw conveyors are one of the oldest conveying methods known to man and still the ideal method for many applications. Though screw conveyors and augers are technically synonymous (any conveyance method driven by rotating threads) the processing...

Magnetic Conveyors

Magnetic conveyors use magnetic fields to transport and manipulate bulk materials either by moving a magnetic belt or gripping ferrous materials through the belt for sorting. These conveyors are commonly used in industries such as mining,...

Vibratory Conveyors

Vibratory conveyors use vibrations to move bulk materials. These conveyors are commonly used in industries such as mining, pharmaceuticals, food processing, and agriculture, where the efficient handling of materials is critical to maintaining...

Spiral Conveyors

Spiral conveyors move units of product vertically where floor space is limited or the product needs to be travelling through multiple floors of a facility. (See bucket elevators for vertical movement of bulk material). Spiral conveyors are...