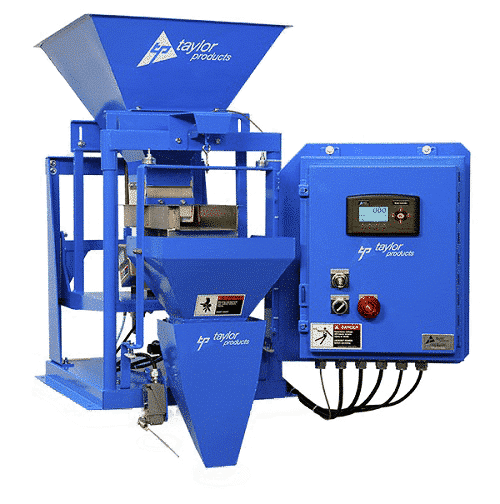

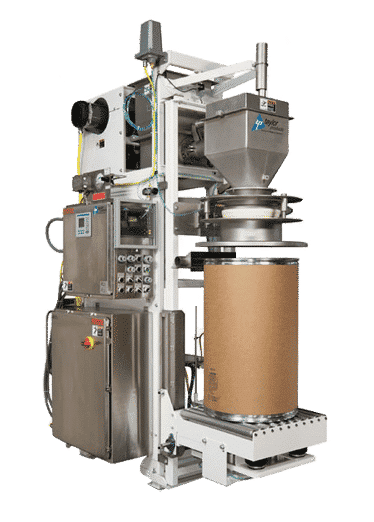

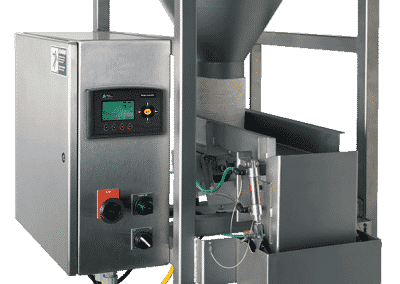

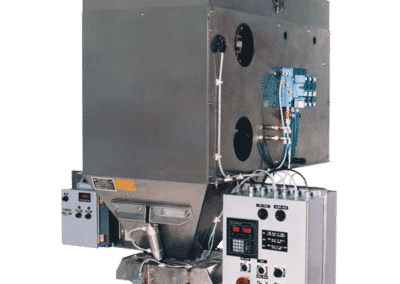

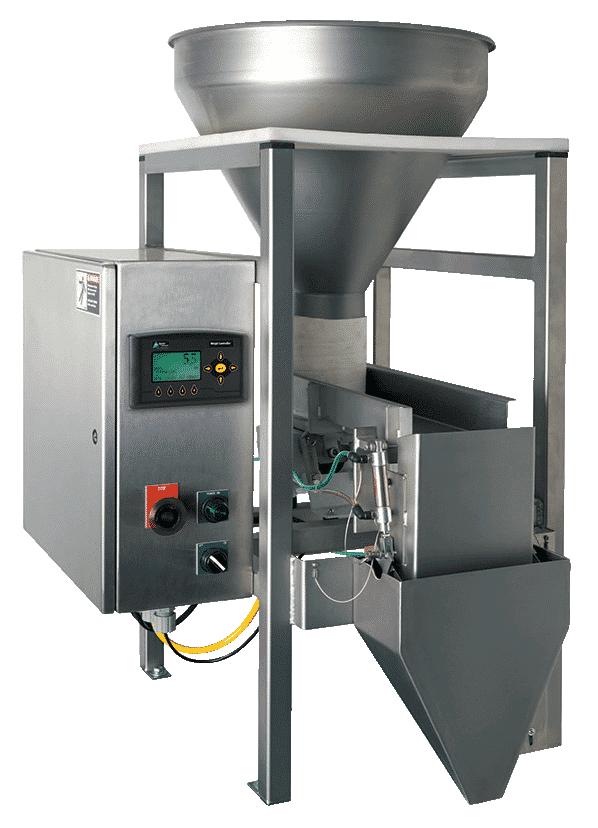

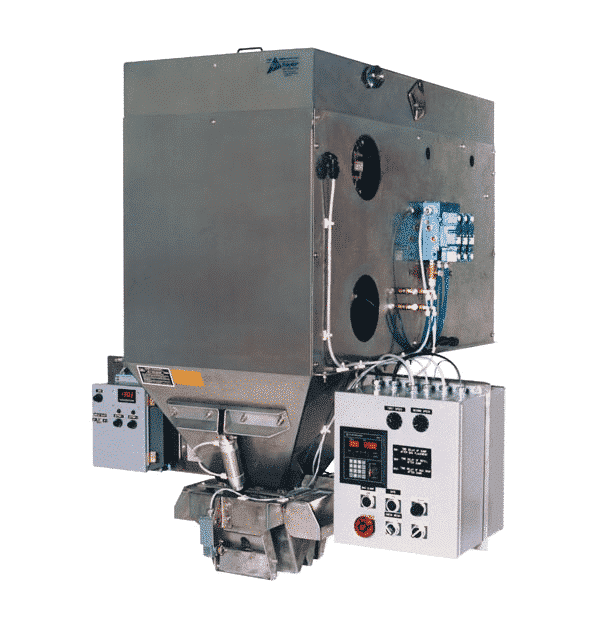

Open Mouth Baggers

Open Mouth Baggers are a type of bagging scale that fills bags, boxes, or totes with loose product. They are used in a variety of industries such as food, agriculture, chemical, and bulk pharmaceutical. These machines provide efficient and accurate filling, and are available in either semi-automatic or fully automated configurations.

There are several key features and benefits of Open Mouth Baggers:

Automation: Open mouth baggers are available in auto and semi-auto configurations depending on the application, but can always fill and close bags at a much faster rate than manual labor. They are usually meant to be paired with bag placers or sealing equipment (can be sewing, heat-sealed, etc.) so processes can be scaled as operations grow.

Accuracy: Open Mouth Baggers are designed to provide accurate filling and weight control, ensuring that each bag contains the correct amount of product. This helps to reduce waste and deviations in quality.

Customization: Open Mouth Baggers can be customized to match your SOP and other equipment, whether up-stream, down-stream, or integrated. They can be fitted with different filling systems, such as gravity, volumetric, or auger-based systems, and we can fabricate any transitions or customizations needed.

Versatility: Open Mouth Baggers are capable of handling a wide range of products, from powders and granules to liquids and pastes. They can also be used with different types of bags, including woven, laminated, and paper bags.

Ease of use: Open Mouth Baggers are designed to be user-friendly and simple for operators to set up and use the machine, reducing man- hours and the risk of errors.

Cost-effectiveness: Open Mouth Baggers can help to reduce costs by increasing productivity and reducing waste. Relatively simple machines, they are also generally low-maintenance and easy to service.

When choosing an Open Mouth Bagger, it is important to consider your product characteristics, and documentation, and technical support that will be available post-sale. To skip the work, give us a call or fill out the form below and they’ll know what’s best for you almost instantly. We provide 24/7 support for existing customers.

Pros

- Flexibility: Open Bag Fillers can accommodate a wide range of bag sizes and materials, making them suitable for a variety of products and applications.

- Ease of Use: Open Bag Fillers are simple to operate and maintain, reducing the risk of operator error and increasing efficiency.

- Speed: Open Bag Fillers are capable of filling bags at a faster rate than manual labor, reducing the time and resources required to complete the packaging process.

- Accuracy: Open Bag Fillers are designed to provide accurate filling and weight control, ensuring that each bag contains the correct amount of product and reducing waste.

- Cost-effectiveness: Open Bag Fillers are often less expensive than valve bag fillers.

- Tighter Closure: Open-mouth bags will close tighter than valve bags, so if the product is sensitive to moisture or is extremely dense and prone to leaking, you will want to use open-mouth bags for more security.

Cons

- Dust Control: Open Bag Fillers can generate dust during the filling process, which can be a problem in certain applications. We have special models for this issue as well as a variety of dust collection systems, so this is application-dependent. See valve bag fillers if the product is particularly light.

- Product Exposure: Open Bag Fillers can expose the product to the environment, increasing the risk of contamination. See valve bag fillers if the product is hazardous.

- Bag Closure: Open Bag Fillers don’t typically provide a means of sealing the bags, which must be done separately. Open-mouth bags will usually be sewn or come with adhesive to be sealed by hand after filling.

Things to consider when choosing between valve and open-bags

- Filling Method: Open mouth bags are ideal for products that are filled using gravity or volumetric filling systems, as these methods require the bag to be open during filling. Valve Bags, on the other hand, are typically filled using pressure or vacuum systems and the valve is used to discharge the product into the bag.

- Product Characteristics: If your product is mildly hazardous, extremely dense, or hygroscopic—readily absorbing moisture from the environment—this will effect which method you use. An open-mouth bagger will create more dust and expose the product to more moisture during filling, but a valve-bag will seal the product tighter during transit and storage.

- Packaging Line Layout: If you simply don’t have the space for a bag closer and the adhesive open-mouths won’t work for your application, you will have to use a valve-bag filler.

- Initial Cost: Open Mouth Baggers generally cost less up-front, but may require a sewing machine.

- Operating Cost: Open mouth bags themselves are less expensive than their valved counterparts, as they do not require a valve to be added, which is an extra manufacturing step.

Why ABM?

ABM is more than just a connection to OEMs. With over 20 years of experience in the industry, we have built a reputation for providing high-quality, reliable, and cost-effective packaging solutions to a wide range of industries.

With a team of experienced engineers and technicians, we provide customized solutions to meet the specific needs of our customers. We work closely with you to understand your requirements and recommend the most suitable bulk packaging solution for your use-case.

We offer preventative maintenance programs for all our equipment to ensure they continue to operate at optimal performance. Our technicians are knowledgeable and experienced, and are available to provide on-site maintenance, repair and support services.

Whether you are looking for a single piece or a cohesive system, ABM Equipment can help scale and automate your process. Contact us below to learn more about our services and how we can help you achieve your production goals.