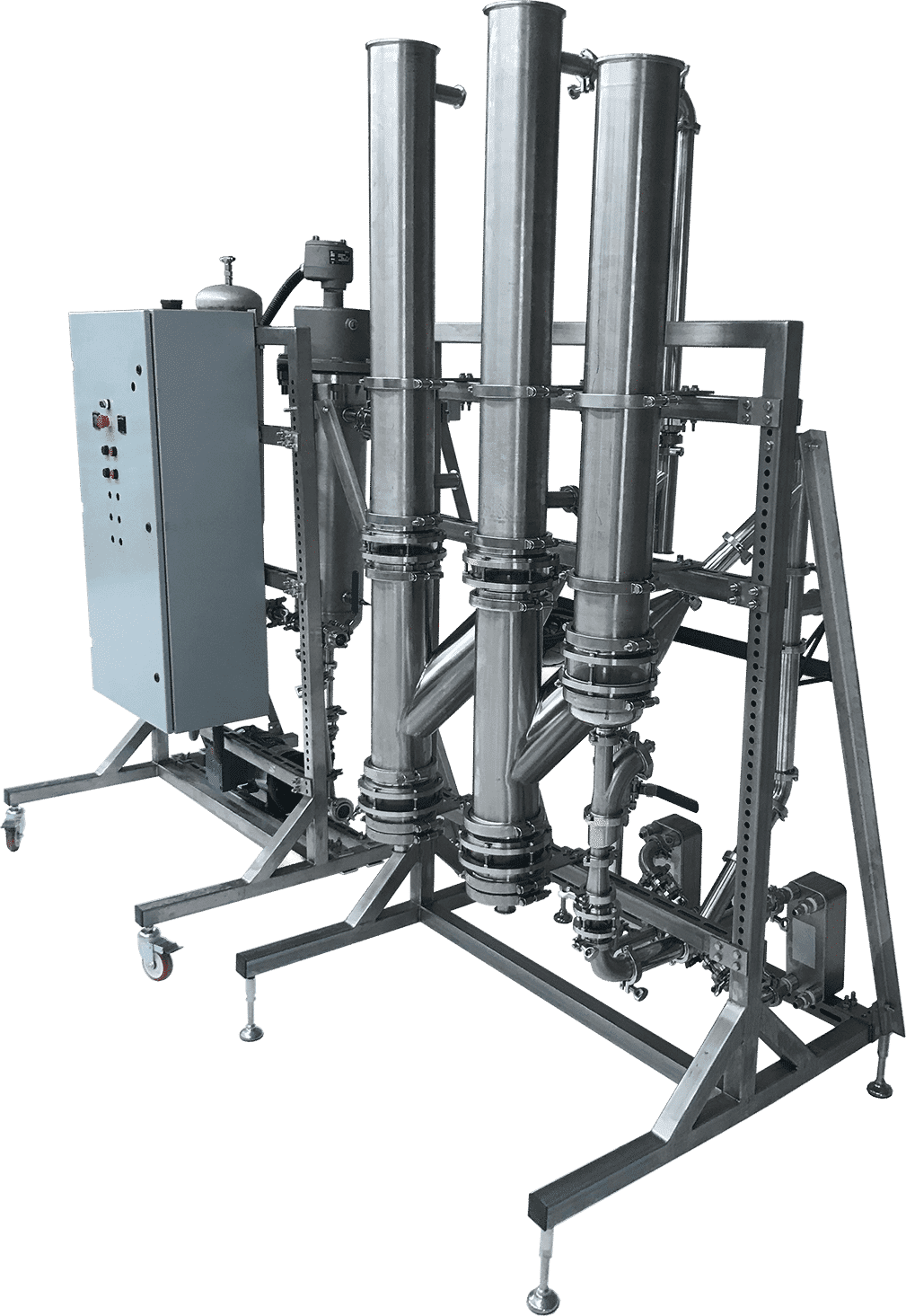

Dual Stage Falling Film Evaporators

Details

No Chiller

Through the use of patent-pending diffusion condenser technology, the Yellowstone falling film evaporators have eliminated the need for expensive chiller systems, which are the most common restrictions of FFE operability. This drastically decreases the energy and consumable requirements for processing facilities.

Simple, Continuous Operation

Our Falling Film Evaporator integrates automatic control systems for ease of use and to decrease processing times. The dosing pump and automated draining systems allow for continuous operation with minimal operator input. Our proven evaporation and condensation rates ensure that you are left with high purity concentrates and solvents, achieved at rapid speeds.

Low Footprint

At just 4’ x 4’ and 8’ tall, the Yellowstone Extraction Falling Film Evaporator can easily fit in your facility, no matter the scale and size. Factoring in the additional space saved by eliminating chiller requirements, the Yellowstone system frees up valuable square footage.

Minimal Degradation

Operating at atmospheric pressure, the Yellowstone falling film does not allow crude to exceed the boiling point of the solvent because the gas is never super-heated. Vacuum can be introduced to the columns via the collection vessel, but this is unnecessary because there is no chiller-induced throughput cap and residence time is less than 5 seconds at low temperatures.

| Heating |

Steam or Electric |

| Solute Max. Temp. | 194˚F (90˚C) |

| Dwell Time | 7 Seconds |

| Additional Equipment | Radiator (Included) |

| Made In | USA & CAN |

Easy-To-Clean

The internal workings of the Yellowstone Extraction Falling Film Evaporator are designed to be easily cleaned in-place using an integrated cleaning cycle function. A clean process will optimize efficiency as well as eliminate contamination between batches.

1 & 2-Stage Configurations

With various configurations available, virtually any preferences can be accommodated. Two-stage falling films are recommended for higher throughputs because they allow higher temperatures to be applied to incoming solution when more solvent is present, and lower temperatures to drier crude. This increases throughput, reduces energy use, and protects oil from being overheated when little solvent is present.