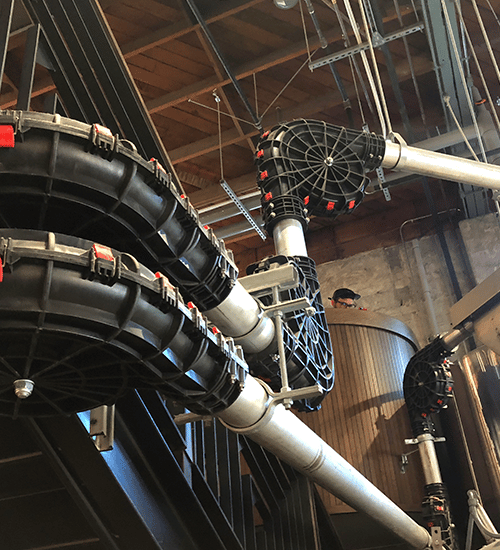

Brewery Chain Disks

Chain disks (also known as chain-and-puck conveying or tubular drag) are the best method for grain handling in breweries. As with all of our handling systems, they come made-to-order with turn-key integration and 24/7 service available.

Scalable

Chain links can be easily separated and joined, allowing flexibility for future changes in the process or facility.

Versatile

Chain disks retain effectiveness about numerous tight corners and vertical runs. This means more options and less hazards.

Gentle

Fewer particulates means less dust in the air, ground, and mash. This leads to less cleanup and higher yield.

Durable

Cable-based systems wind up over time and the metal in augers wears through tubing. Chain disks involve minimal friction.

Fast

4-inch systems can move up to 300 lbs. of whole grain and 200 lbs. of milled grain per minute.

Chain disks are functionally superior to augers in every way. They last longer, look better, and are quieter. But most importantly, they’re faster and gentler on milled grain. The official rate for 4″ systems is 200 lbs/min, but in practice the rates are higher. And if you’d like to step it up even further, some of our customers run two chain disks side-by-side to mash in almost instantly, as shown here.

Chain disks are our go-to method for grain and malt conveying because of their versatility. Because they can tolerate long runs and vertical climbs, we can connect silos, bulk bag unloaders, and specialty hoppers with one drive. The same chain disk system can then carry the in-feeds to the mill, loop back around, and take it from mill to mash.

Operating Principle

Chain disks use pucks connected by chain to drag grain or malt through tubing, which can be either metal or plastic. Their gentleness stems from the low amount of friction inherent between grain and these materials, as well as the low-friction components. Wheels at each corner suspend pucks away from the tubing at turns, reducing wear within the system—which augers are notorious for. This allows a single drive to convey product up to 2,000 ft with up to 24 turns and as many outlets as needed. The distance between the pucks and the piping make it seem like there would slippage/rollback up vertical climbs, but even milled grain creates a bridge larger than this gap.

Details

Manufacturers and types of material used (such as PVC, aluminum, or steel) will affect rates and effective runs listed below, so give us a call or fill out the form to go over your application. We’ll answer your questions or get you a quote.

Diameters

2-3/8″ (up to 55 lbs/min whole grain, 39 lbs/min milled grain)

4″ (up to 300 lbs/min whole grain, 200 lbs/min milled grain)

Tubing Options

Galvanized steel

PVC (clear or colored)

Dust Egress

The gaps in chain disk elbows are larger than the minimum particulate size of grain dust, so they are not technically dust free. However, components free of vibration rarely leak in practice, so dust can be cut significantly by placing metal tape around the mill connection. This is how many brewers and distillers achieve “dust-free” conveyance. For a “dust-free” system, however, keep in mind you need a dust-tight mills, which is available officially.