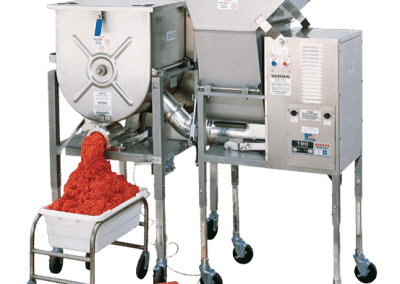

Coarse Grinder

The Course Grinder from Hollymatic is a first-pass solution for course and whole-muscle inputs. It can be attached to a pattymaker directly for course-grind end products or be coupled with a mixer-grinder for finer grinds or blended products.

| Motor |

7.5 HP |

| Power Options | 200 V, 3 Ph., 60 Hz., 25 A 230/460 V, 3 Ph., 60 Hz., 22/11A 575 V, 3 Ph., 60 Hz., 8.8A 220/380 V, 3 Ph., 50 Hz., 24/14A |

| Dimensions | 26.25″ W x 34″ L x 57–74″ H (adjustable) |

| Weight | 640 lbs. |

| Made In | USA |

High Throughput

Capable of up to 6,500 lbs./hr. throughput, the Course Grinder comes stock with a 100-lb. hopper which can be used to feed product manually or account for overflow from a continuously-feeding conveyor. The motor can optionally be reduced to roughly half-speed and the hopper size can be doubled to facilitate integration with other equipment.

Self-Feeding

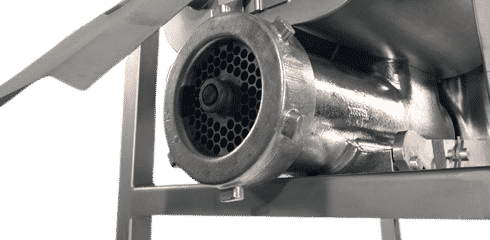

The dual augers are self-feeding, meaning they completely clear the hopper at the end of each batch. This simplifies the transition between different products and cleaning procedures. The grinder comes with a #52 head that can be swapped at request for specialty applications.

High Torque

The 7.5 horsepower motor delivers high torque to the augers for consistent speeds and even grinds. The enclosed drive & seal lubrication minimize maintenance.

Safety Interlocks

Whether there is a raised optional extension or opened lid, the safety interlocks shut down the unit when opened.

Tilting Hopper

A tilting hopper allows easier access for sanitization.

Mobile & Adjustable

Adjustable legs allow 23” of flexibility in unit height, from 57–74” to the top of the hopper. Each leg has a swivel heavy-duty caster for better mobility.

Standard Features

- Stainless steel material

- Adjustable height

- Swing open tub

- Adjustable high-elevation legs

- Self-cleaning dual augers

- Heavy-duty and large casters

- Compatible with Gemini system

- No need to get a specialized or custom tool for disassembly

- Screw feed speed of 120 RPM or 180 RPM

- Inspection holes in lid

- Straightforward and easy-to-use push-button controls