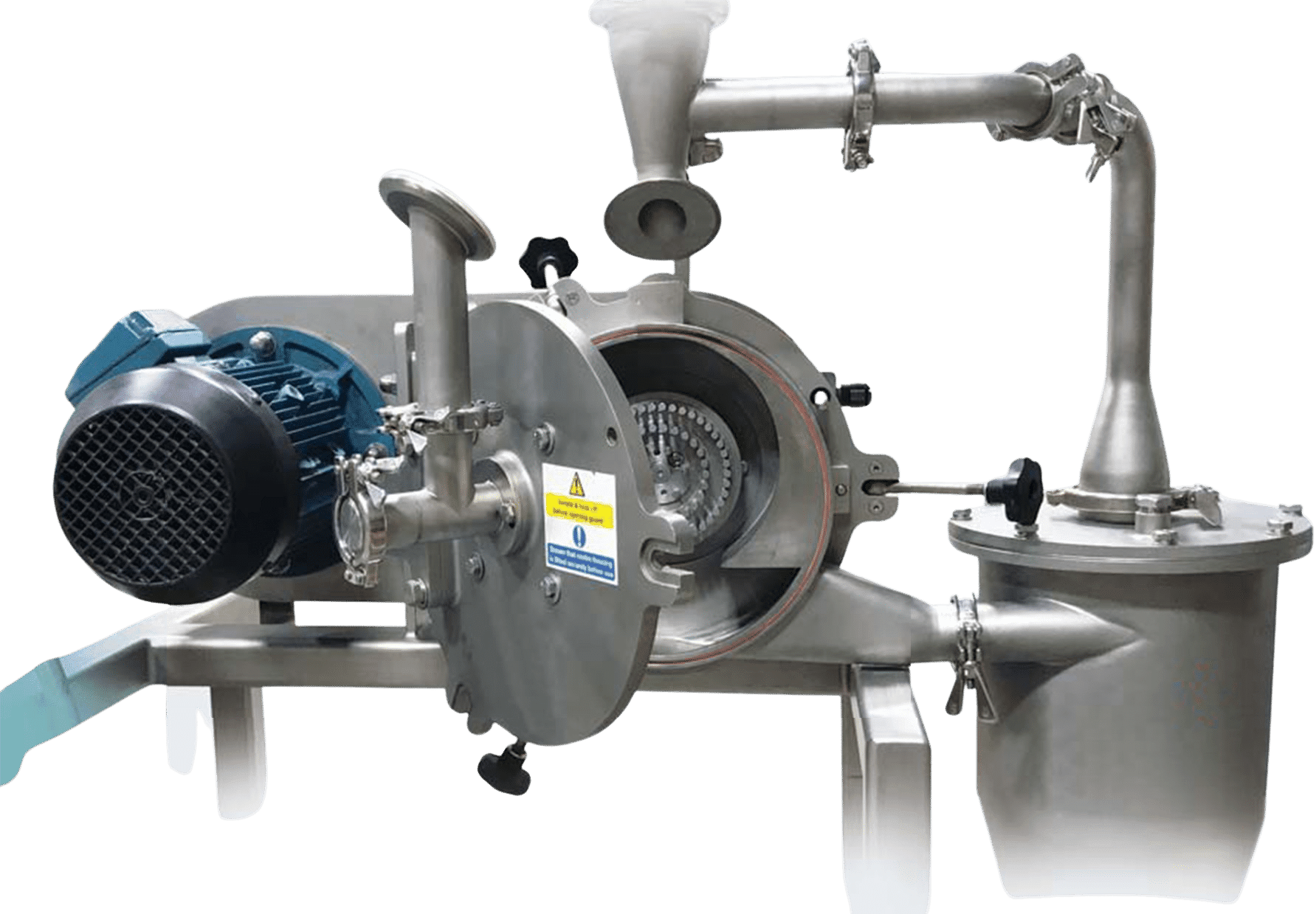

Universal Mills

Options

The Universal Mill can either be located at high elevations or at ground level. It is linked to the milled-powder collector, which can be connected via hopper or external filler-receiver (see below).

- Cryogenic configuration (see below)

- Inert configurations (see below)

- Explosion containment using a 10 bar PSR design

- Inert gas like nitrogen can be used to replace combustible gases or air in the system.

- Explosion protection through bursting panels

- Explosion suppression using a quench system or suppression system

- Compact design changes

Temperature-Controlled Milling (+Cryogenic Milling)

Liquid nitrogen can be used to precisely control the temperature of product, which can protect it from degradation and improve efficiency. These temperatures can be held at cryogenic levels (as low as –150° C) for products that are difficult to mill at higher temperatures, need lower temperatures to reach finer grinds, or need further assurance against explosion.

Inert Milling

To protect against explosions, the Universal Mill can operate under vacuum to remove oxygen or have the oxygen replaced with inert gases like nitrogen or carbon dioxide.

Popular Applications

Food

- Powdered sugar 6X – 10X Grade

- Microfine salt

- Rice flour

- Wheat flour

- Casein and whey protein

- Spices

Pet Food

Pharmaceuticals

Chemicals

- Sodium bicarbonate

- Trona

- Sulphur

- Nitrates

- Grind fine powders

| Motor Sizes | 3 HP – 125 HP |

| Grind Sizes | 100 μm – 20 μm |

| Made In | USA |

Mill guide by particle size

Operating principle