Lump Breakers

Lump breakers reduce particle size of large lumps or aggregates. Often used in the processing of bulk materials, such as chemicals, pharmaceuticals, food products, and minerals, they are often used to improve a material’s flow properties, make it more compactable, or prepare it for further processing.

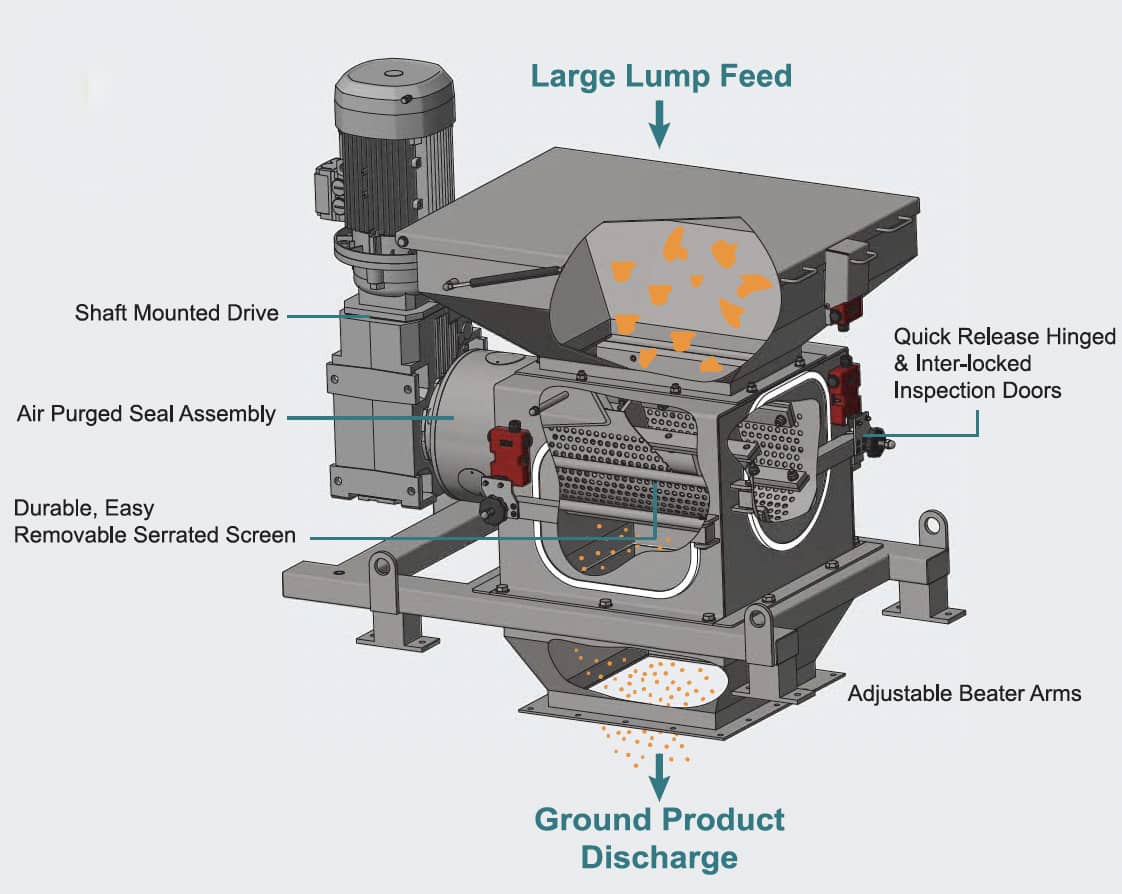

Lump breakers typically consist of a rotating shaft with a series of interlocking blades or hammers mounted on it. The material is fed into the lump breaker, and as it rotates, the blades or hammers break the lumps into smaller pieces. The size of the final product can be controlled by adjusting the speed of the rotation, the size and shape of the blades or hammers, and the gap between the blades or hammers and the housing of the lump breaker.

Our Lump Breakers can also be used to classify materials based on particle size by use of a built-in screen. All Lump Breakers can be customized on project-by-project bases to optimize their respective application. For example, they can also be equipped with cantilever grinder beaters for fine chemical, pharmaceutical, and food applications. They employ a number of thoughtful design elements such as non-drive-end access doors, which allow for easy-access to the screen for cleaning and exchanges.

Functions

- Breaking soft to medium-hard aggregates

- Pre-Grinding large lumps into smaller pieces for further milling

- Milling product to as low as 2mm diameter

Options:

- Cantilever shafts without seals or end bearings for improved hygiene

- Easy-access doors

- Pressure-rated design for inline applications

- Diverse feed and collection ancillary parts

- Multiple Drive Configurations

Features

- Interchangeable beaters

- Interchangeable screens

- Low-speed, high torque operation

- Easy-access screen doors

- Minimal generation of fines

- Minimal heat generation

- Wide range of screen options and equipment configurations depending on application

- Low-noise

Popular uses

- Placement after bulk bag unloader or de-bagging to prime materials for processing

- Creating biscuit sprinkles for ice cream and dessert toppings

- De-lumping chocolate for rework

- Reducing pop-corn size for cereal bars

| Sizes Available |

Lab to large-scale industrial

|

| Grind Sizes | 150 mm – 2 mm |

| Screen Sizes | 30 mm – 3 mm |

| Made In | USA |

Mill guide by particle size

Operating principle