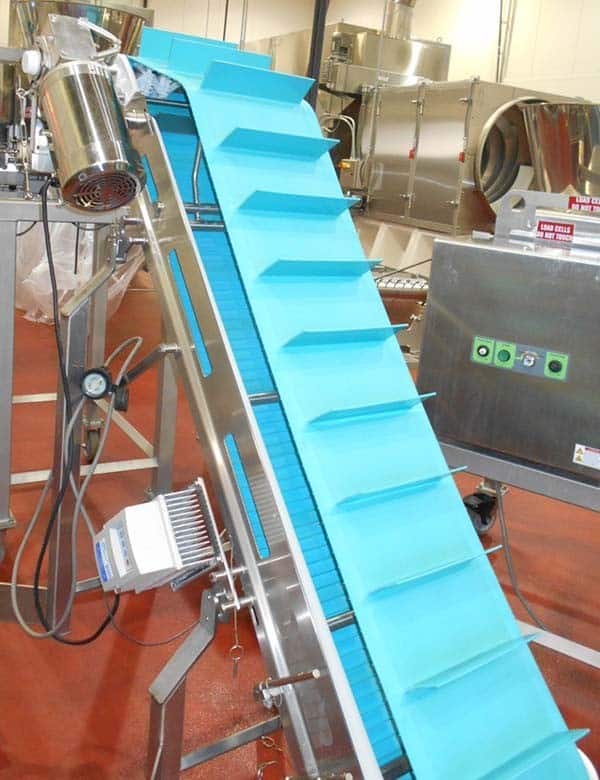

Cleated Belt Conveyors

Cleated belt conveyors are standard conveyors with raised edges (cleats) to keep product in place and prevent it from sliding or falling off the belt as it moves. This allows greater capacity and conveyance up slopes. The cleats can be made of various materials such as plastic, rubber, or metal, and can be arranged in different patterns depending on the type of material being conveyed and the needs of the application.

Cleated belt conveyors are commonly used in a variety of industries, including mining, construction, agriculture, and manufacturing. They are most commonly used in food manufacturing and small parcel handling and sorting. Cleated belts are often known as “crossbelts” because, with set spacing between each package or tem, they can easily be sorted cross-wise.

There are several factors to consider when choosing a cleated belt conveyor, including the type of material being conveyed, the conveyor’s load capacity, the desired speed and capacity of the conveyor, and the overall layout and design of the system. It is important to select a conveyor that is suitable for the specific needs of the application to ensure optimal performance and efficiency. Call us or submit a form today to skip the work find out what the right solution is for your process right away!

Cleated belt designs are typically combined with corrugated belts but are not necessarily the same.