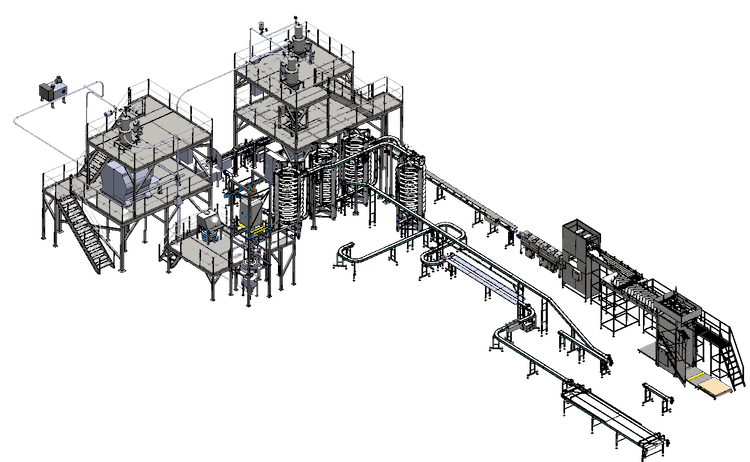

Conveyor System Design

Having all the factors hashed out in your conveyance design the first time saves considerable time and pain. Our engineers have encountered hundreds of products, applications, and dilemmas, and are adept at finding creative solutions to accommodate the unique hurdles in your process. They are well-versed in nearly all conveyance options available on the market and can take uncertainty out of your project.

Determine Application Requirements

The first step in installing conveyors is making sure the intended conveyors are the best for the application. This will be impacted by type of material or product being transported, the speed and volume of the operation, the distance and path of the conveyor, and any special requirements such as inclines or declines, curves, or sorting capabilities.

Select Conveying Equipment and Components

After identifying the application requirements, the next step is to select the appropriate conveying equipment and components. There are several types of conveyors available, including belt, roller, screw, and pneumatic conveyors, and the selection will depend on the characteristics of the material being transported and the specific requirements of the application.

Other components that may be necessary include drives, motors, sensors, and control systems. These components must be selected to ensure compatibility with the selected conveyor type and meet the performance criteria of the application.

Determine Conveyor Layout and Design

Once the best methods are identified, an engineer will draw your system on auto-cad and will go over it with you on screen-share to explain the benefits and drawbacks of your available options, as well as placements of guards, emergency-stops, and interlocks if applicable. They will review easy-to-overlook items like safety, convenience, accessibility for emergencies and maintenance, and proximity to applicable resources.

Calculate System Capacity and Power Requirements

The next step is to calculate the system capacity and power requirements based on the design parameters. This involves determining the required conveyor speed, capacity, and power necessary to operate the system as well as capacity headroom for surges.

If you’re in need of conveyor installation services, fill out the form below or give us a call. Our team is here to answer any questions you may have and to provide you with a customized quote for your project. We also provide conveyor installation and service after-the-fact.

Screw Conveyors

Screw conveyors are one of the oldest conveying methods known to man and still the ideal method for many applications. Though screw conveyors and augers are technically synonymous (any conveyance method driven by rotating threads) the processing...

Magnetic Conveyors

Magnetic conveyors use magnetic fields to transport and manipulate bulk materials either by moving a magnetic belt or gripping ferrous materials through the belt for sorting. These conveyors are commonly used in industries such as mining,...

Vibratory Conveyors

Vibratory conveyors use vibrations to move bulk materials. These conveyors are commonly used in industries such as mining, pharmaceuticals, food processing, and agriculture, where the efficient handling of materials is critical to maintaining...

Spiral Conveyors

Spiral conveyors move units of product vertically where floor space is limited or the product needs to be travelling through multiple floors of a facility. (See bucket elevators for vertical movement of bulk material). Spiral conveyors are...

Tubular Drag Conveying Systems

Tubular Drag ConveyorsTubular drag conveyors are great for most non-abraisive, free-flowing products including powders, pellets, and granules. Capacities can vary depending on the configuration and product, but as a reference, tubular drag...

Tube Belt & U-Belt Conveyors

Tube belt conveyors and u-belt conveyors are most commonly used in industrial settings to transport bulk materials. They are open along the run where product is being loaded, then are closed by devices and rollers. However, there are some key...

Bucket Elevators

Bucket elevators are used to vertically lift bulk materials. They consist of a series of buckets attached to a belt or chain, which runs over a pulley or sprocket at the top and bottom of the unit. The buckets scoop up material at the bottom and...

Chain Conveyors

Chain conveyors, not to be confused with chain-driven belt conveyors, use gear-driven chains to move materials along a conveyor path. Depending on the design these conveyors can move large, heavy objects such as boxes and pallets, or they can move...

Roller Conveyors

Roller conveyors use rollers, bearings, and a little bit of gravity to transport products and materials. They are commonly used in manufacturing, warehousing, and distribution centers to move items efficiently and accurately. Benefits One of the...