Conveyor Engineering

ABM Equipment provides comprehensive conveyor engineering services for food, pharma, chemical, and aggregate applications. Our experienced process engineers ensure you’re using the optimal conveyance method, that the equipment is built with the optimal materials and features, and that the final system operates as a cohesive unit. When needed, our mechanical engineers then custom-design conveyor models for your application and our fabrication department integrates and supports your system going forward.

For ALL conveyors including tubular, vibratory, screw, and pneumatic.

From initial design to installation and maintenance, we ensure that your conveyors and systems are optimized for efficiency and reliability.

Our conveyor engineering services begin with a thorough analysis of your specific needs and operational requirements. We take into consideration factors such as material and product characteristics, flow rates, and space constraints to design a conveyor system that maximizes productivity and minimizes downtime.

By choosing our conveyor engineering services, you can benefit from our in-depth knowledge of conveyor systems and our commitment to delivering high-quality solutions. We utilize the most recent technology and industry best practices to ensure that your conveyor system moves your product efficiently and safely.

We have a broad range of experience in most types of material handling and logistics applications and understand that equipment is ultimately useless if it’s not supported. We service what we sell by policy, provide 24/7/365 support for customers, and offer preventative maintenance agreements to ensure maintenance schedules aren’t neglected.

Reasons Conveyors and Conveyance Systems Need Customization

Unique Operational Needs

Each application and space has its own unique operational needs whether it’s space constraints, environmental threats, or integrating with existing equipment, and it can be very difficult to find out-of-the-box models with the right mix of features and tolerances. By tailoring the system to your needs, we can optimize efficiency and your bottom line. We can customize location of service panel, upgrade the washdown rating, change how the belts or screws are removed, add dust control integration, change the mounting method of drives and accessory tools, or virtually anything else that needs to be done.

Varying Material Characteristics

Materials being transported can vary greatly in size, shape, and characteristics. Having a custom system allows you to harness or accommodate these traits to prevent product damage and optimize flow. A few days of engineering time can save hundreds of days on the floor.

Process Integration

Conveyor systems need to seamlessly integrate with other processes and equipment in your facility. By customizing your conveyors from the beginning, we can ensure smooth integration, efficient material transfer, and minimized bottlenecks.

Cost Savings

Custom conveyor systems can be more cost-effective up-front by ensuring that you only invest in the features and capabilities that essential to your operation. They can also save money in the long-run by reducing wear on the conveyors and product.

Why Choose Us

Experience

With over 40 years of experience across a number of industries—and most likely with products like yours—we bring an understanding of your materials and how they will behave in different circumstances. This allows us to reach better solutions without reinventing the wheel or bringing in third parties.

Quality and Reliability

ABM Equipment has long been committed to systems that make sense in the long-run. From the selection of materials to the utilization of technology, we prioritize quality and reliability in every aspect of our work. Our systems can be built to endure harsh environments over long periods of time.

Comprehensive Services

Our conveyor engineering services cover the entire project lifecycle, from design to maintenance. Our end-to-end approach offers a headache-free experience for your operations and project managers. Our team is always available to provide support throughout the project.

Fill out the form below or give us a call to find out how we can add value to your project!

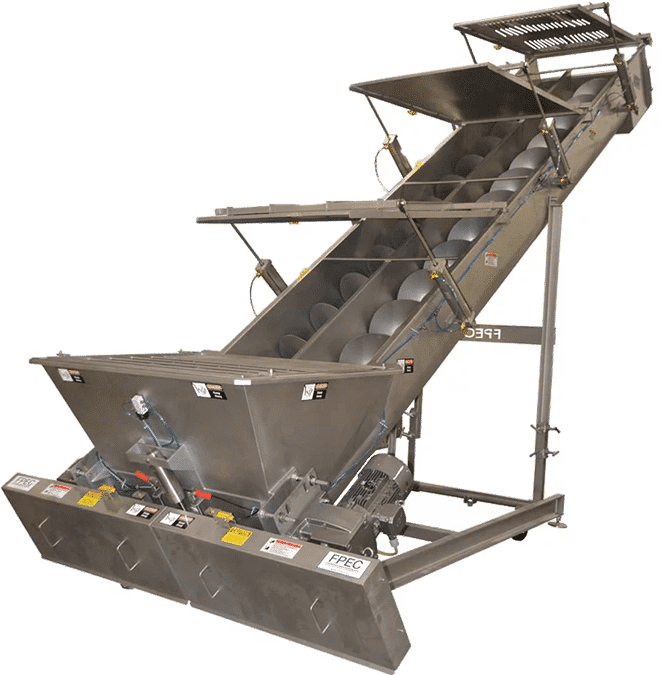

Screw Conveyors

Screw conveyors are one of the oldest conveying methods known to man and still...

Magnetic Conveyors

Magnetic conveyors use magnetic fields to transport and manipulate bulk...

Vibratory Conveyors

Vibratory conveyors use vibrations to move bulk materials. These conveyors are...

Spiral Conveyors

Spiral conveyors move units of product vertically where floor space is limited...

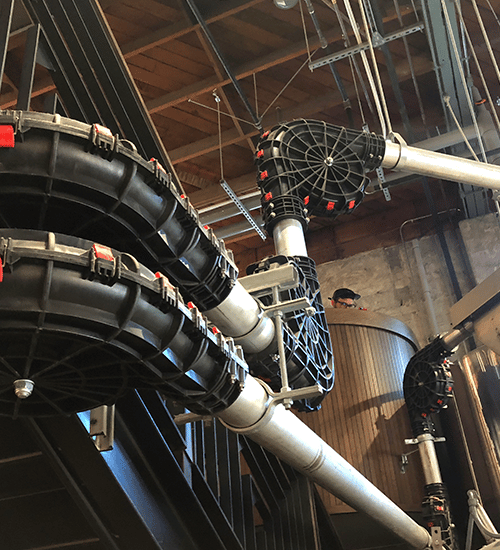

Tubular Drag Conveying Systems

Tubular Drag ConveyorsTubular drag conveyors are great for most non-abraisive,...

Tube Belt & U-Belt Conveyors

Tube belt conveyors and u-belt conveyors are most commonly used in industrial...

Bucket Elevators

Bucket elevators are used to vertically lift bulk materials. They consist of a...

Chain Conveyors

Chain conveyors, not to be confused with chain-driven belt conveyors, use...