Comparing Mill Types

There are several types of mills that are used for size reduction of materials, including roller mills, hammer mills, pin mills, disc mills, and cone mills. Each type of mill has its own specific features and characteristics, and is more suitable for certain types of materials and applications.

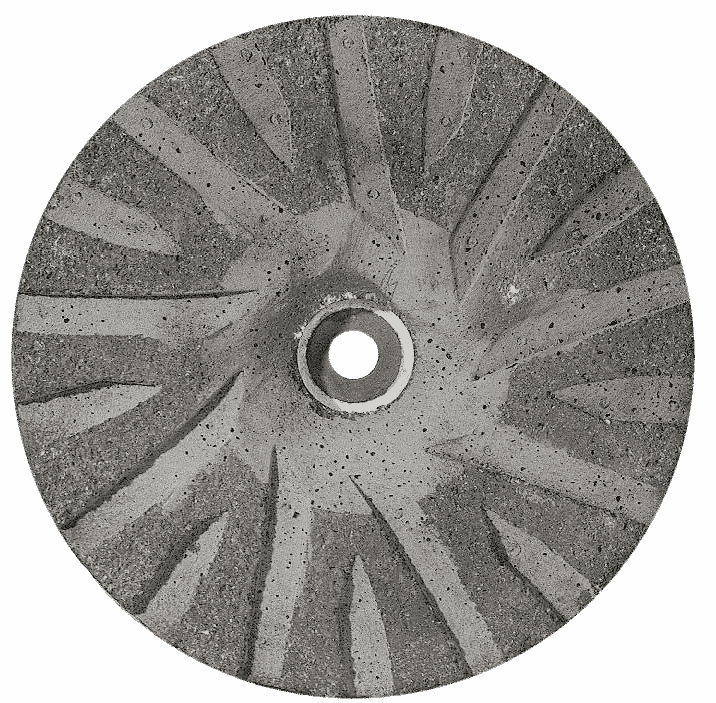

Disc Mills

Disc mills use flat, disc-shaped plates to crush or grind material. They are typically used for medium to fine grinding, and are capable of producing a wide range of particle sizes. Disc mills are suitable for grinding materials that are relatively soft and not too abrasive, such as grains, seeds, and certain types of food products.

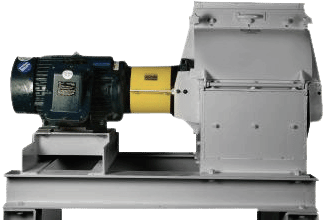

Hammer Mills

Hammer mills use rotating hammers to crush or grind material against a screen. They are typically used for medium to coarse grinding, and are capable of producing a wide range of particle sizes. Hammer mills are suitable for grinding materials that are more abrasive or hard, such as animal feed, grains, and minerals.

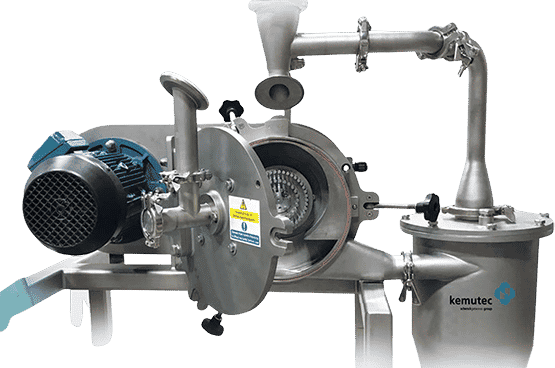

Universal Mills

Universal mills use interchangeable turbine and pin configurations to provide optimal grinds for the most flexible range of inputs and finished products possible use a rotating pin or rod to grind or crush materials into smaller particles. They are often used to reduce the size of hard or abrasive materials, and can grind a wide variety of materials, including minerals, chemicals, and food products.

Pin Mills

Pin mills use interleaving pins, also called needles, to crush or grind material between them. They are typically used for fine grinding, and are capable of producing very small particle sizes. Pin mills are suitable for grinding materials that are relatively soft and not too abrasive, such as some types of food products and chemicals.

Turbine Mills

Turbine mills use a fluid such as water, steam, or air to rotate blades or vanes.

Roller Mills

Roller mills use cylindrical, opposing rollers to crush or grind material. They are typically used for medium to fine grinding, and are capable of producing a wide range of particle sizes. Roller mills are suitable for grinding materials that are relatively soft and not too abrasive, such as grains, seeds, and certain types of food products. They are also useful for gentle, consistent applications like cracking grain.

Cone Mills

Cone mills use conical apparatuses to crush or grind material against a screen. They are typically used for fine grinding, and are capable of producing very small particle sizes. Cone mills are suitable for grinding materials that are relatively soft and not too abrasive, such as some types of food products and chemicals.

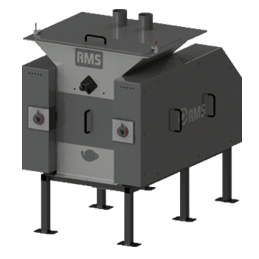

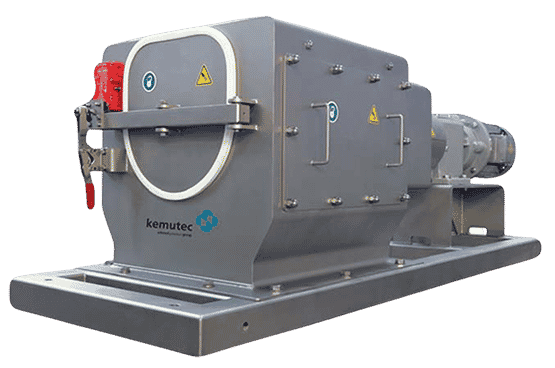

Lump Breakers

Lump breakers break down large lumps or aggregates of material into smaller pieces to improve flow, storability, or prepare it for further processing. Lump breakers typically consist of a rotating shaft with a series of interlocking blades or hammers mounted on it. The material is fed into the lump breaker, and as it rotates, the blades or hammers break the lumps into smaller pieces.

Air Classifiers

Air classifiers are mechanical devices that use airflow to separate particles based on size, shape, and density. Air classifiers work by drawing air through a chamber, which creates a current that lifts the lighter particles up and away from the heavier ones. The lighter particles are then collected and the heavier ones are discarded.

For more information on any of these mills than is supplied on their respective pages, feel free to reach out via the phone or form below.