Dairy 3A Screeners

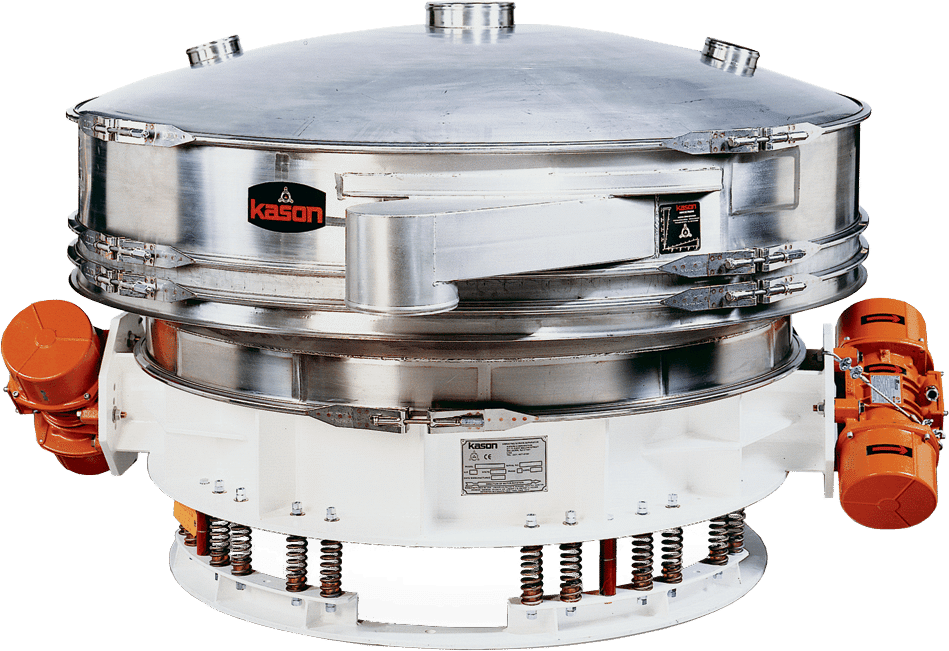

3-A sanitary vibratory screeners are the best option for removing impurities from milk, cream, cheese, and other dairy products because the vibration reduces pooling and allows more flow-through per square inch. Forced screening is not recommended as screen breakages are the second most common source of metal contaminants in dairy products (more on this in the Costco section below). As with most equipment we sell, these gap-free screeners have been optimized for the application and are available in sizes from 24 to 60 inches in diameter.

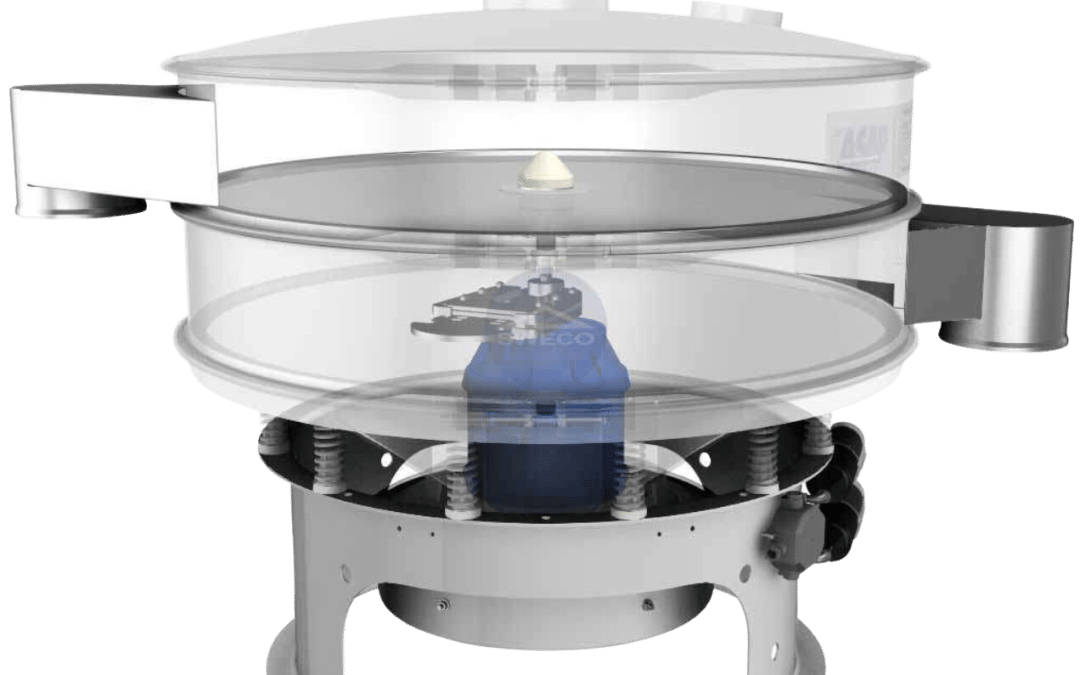

Designed to scalp oversize particles as small as 38 microns (400 mesh) from dry bulk materials or solids-laden slurries, this unit can be disassembled without any tools for rapid sanitizing. The interlocking flange of the screen frame completely encompasses the support ring of the screen, allowing the wire mesh of the screen to extend entirely to the interior walls of the frame, eliminating the gap found in conventional screeners where materials could accumulate.

The sanitary, gap-free design can eliminate contamination caused by bacterial growth while also improving sanitizing efficiency, making it suitable for food, dairy, and pharmaceutical products, as well as other contamination-sensitive products. The screens are mounted on support rings using FDA-approved epoxy and sealed with FDA-approved gasket material. They can also be provided with a mesh-tolerance certificate. The wire mesh screening material is available in 304, 316, and “magnetic” 400-series stainless steel that can be captured by a downstream magnet if broken. They can also be equipped with either single or twin imbalanced-weight gyratory motors and can be supplied with a dust-tight cover.

Low Profile Option

The low-profile option uses two unbalanced-weight gyratory motors located on opposing exterior sidewalls, instead of a single motor positioned below the screening chamber, which greatly reduces the minimum height requirement. This low-profile configuration allows on-size particles to pass quickly through the screen in a vertical discharge path at higher rates than circular screeners that have centrally mounted gyratory motors and horizontal discharge paths. Any oversize material can be manually removed or eliminated using a vacuum.

A Word About Screeners and Costco’s X-Ray Exception

Although untrue, Costco believes that x-ray cannot find metals in dairy products, so they provided an exception in their universal x-ray requirements for suppliers. On these grounds they said dairy producers could use screeners instead of x-ray. If satisfying Costco’s requirements is your primary goal, these vibratory screeners are the safest to use. But if foreign material contamination is a high priority for you, we recommend using x-ray anyway, because broken screens are the largest cause of metal contaminants in dairy products, after mixers. If the cost of x-ray is prohibitive for your company, a cheaper precaution is to use a centrifugal sifter with a mesh screen.

If you have any questions or would like a quote, simply fill out the form below or give us a call!

Related Equipment

Vibratory Screeners

Vibratory screeners are versatile and efficient devices used for separating and sorting particles of different sizes and shapes. They are commonly used in a variety of industries including food, dairy, chemical, pharmaceutical, and mining, to name a few.

Our vibratory screeners are available from 18-100″ diameters with up to 5 decks and any combination of optional configurations to fit any project. These optional configurations include sanitary, gap-free, lift-assist lids, CIP, various solutions for difficult products, ultrasonic, and more. To skip the thinking give us a call to get the best solution for your job quoted.

Static Sieves

Static sieves use large mesh grates or ridges spaced so they remove predetermined impurities from raw materials. Scalping sieves are typically smaller, enclosed static sieves which are placed in-line in processing systems to remove large granules...

Tube Belt & U-Belt Conveyors

Tube belt conveyors and u-belt conveyors are most commonly used in industrial settings to transport bulk materials. They are open along the run where product is being loaded, then are closed by devices and rollers. However, there are some key...

Bucket Elevators

Bucket elevators are used to vertically lift bulk materials. They consist of a series of buckets attached to a belt or chain, which runs over a pulley or sprocket at the top and bottom of the unit. The buckets scoop up material at the bottom and...