Industrial Scale - High throughput falling film system Efficient - Designed with operating expenses in mind Continuous Flow - Produces lean, solvent-free product Automated - Fully automated suite cGMP - Forward compliant design...

From milling to distillation, ABM helps producers scale their processes with consistent, profitable systems. ABM builds, sources, and sells current best solutions with system design, integration, and 24/7 emergency service.

ABM Equipment builds, customizes, and services a select number of pieces used in extraction. In order to provide processors with the single point of contact our customers expect, we’ve teamed up with experts who focus solely on the design and integration of extraction systems. Together we offer complete systems from whole, wet plants through all sorts of final products including some edibles.

Browse some of the individual pieces you will find in a complete system.

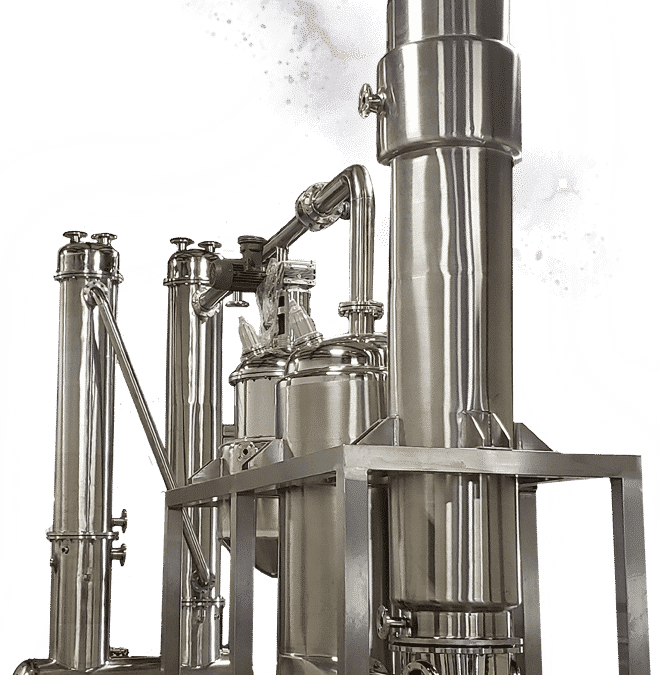

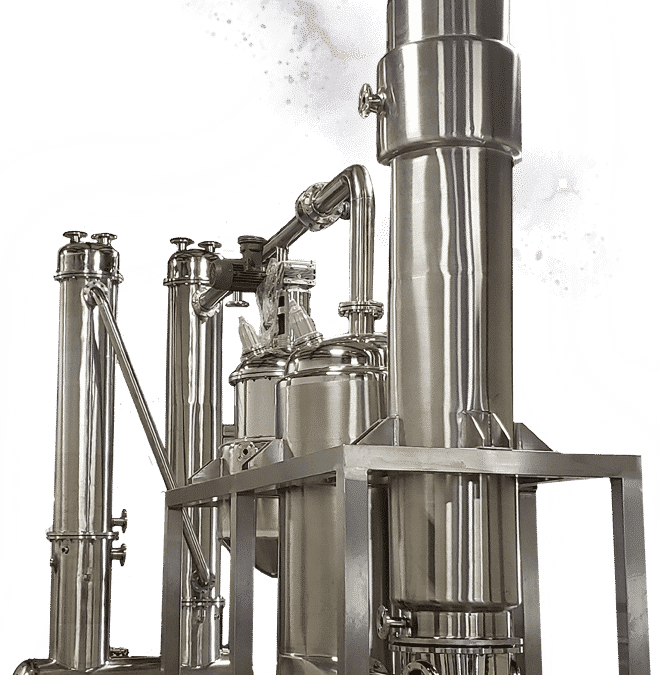

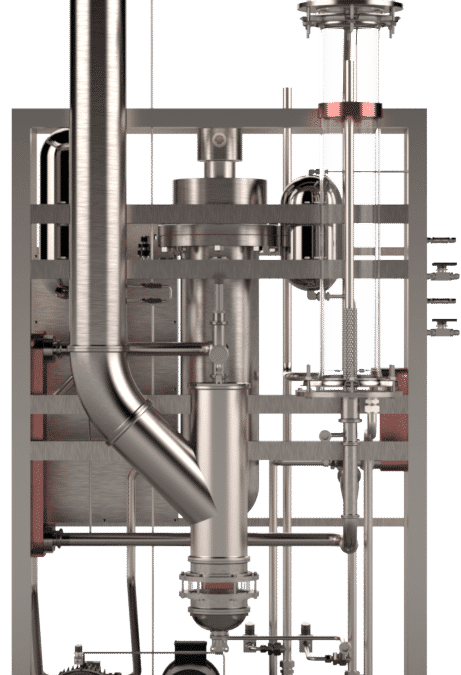

Industrial Scale - High throughput falling film system Efficient - Designed with operating expenses in mind Continuous Flow - Produces lean, solvent-free product Automated - Fully automated suite cGMP - Forward compliant design...

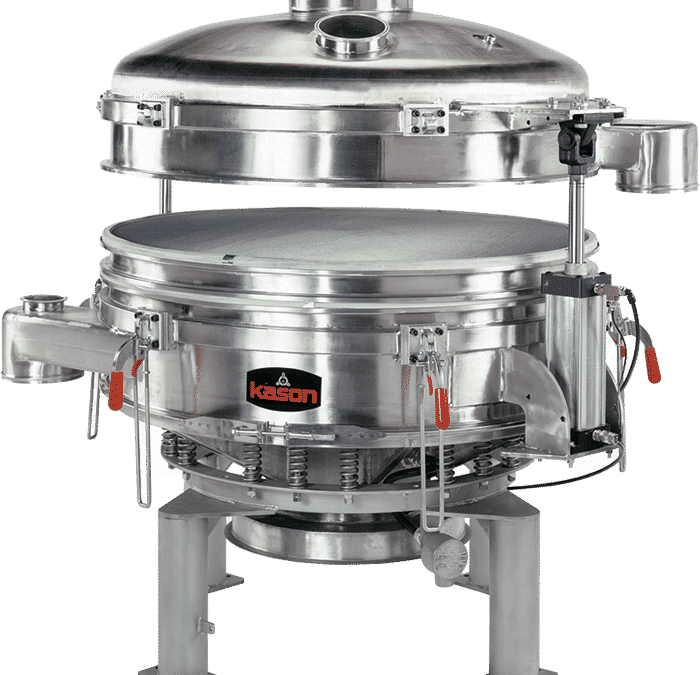

Ice hash machines are vibratory screeners with specialized configurations. First, the bud is mixed with ice-water in an agitated, hopefully jacketed tank, which causes the non-herbanoid organics to swell and the trichomes to...

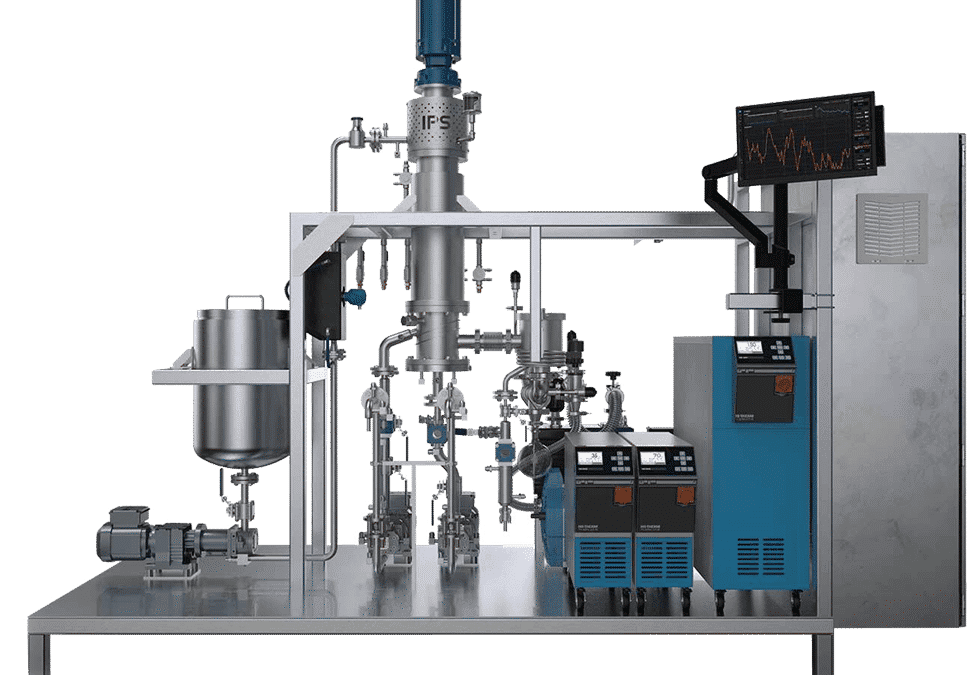

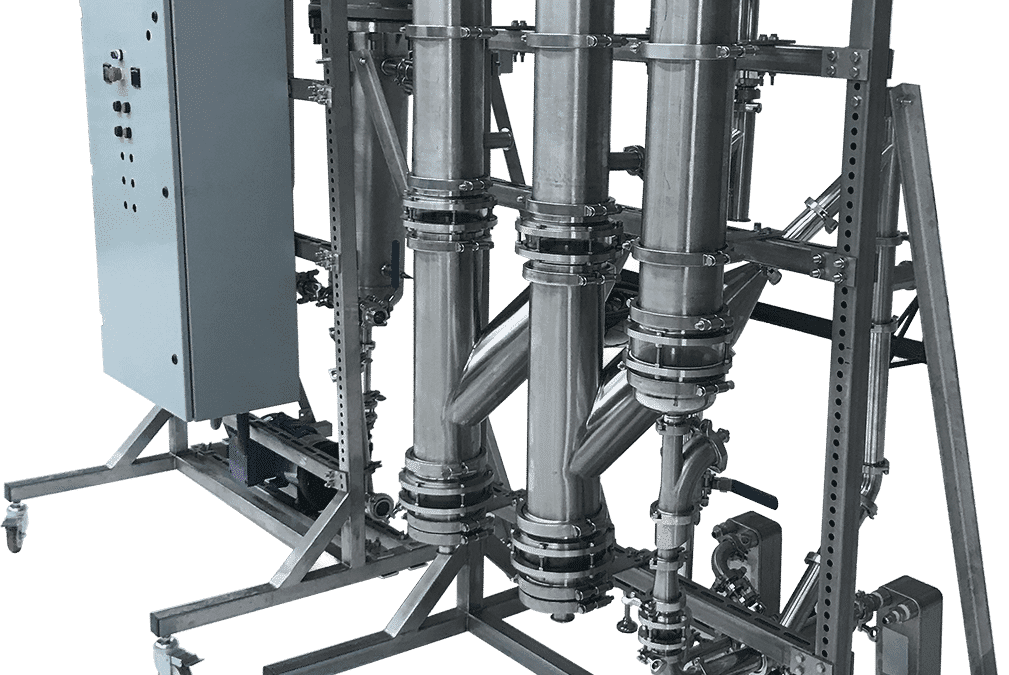

1–3 Column Skids 5–60 LPH Made In The USA Full-Auto Available GMP-Forward Install, Training, & Support InCon’s rolled film evaporators are the industry standard for distillation; they are shipped and serviced directly from...

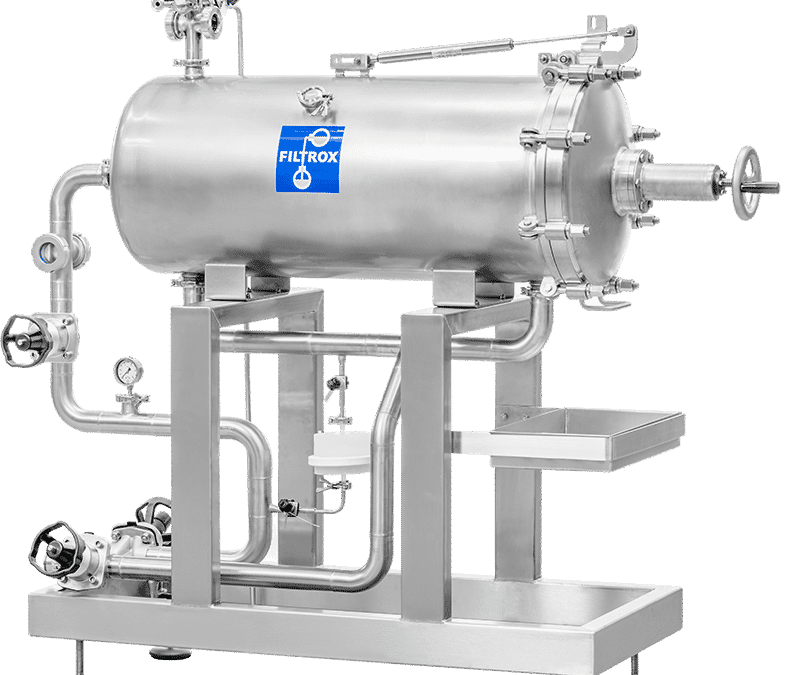

Go straight from winterization to clear oil with high-grade lenticular filters. Washable depth sheets remove all oversized particles and activated carbon sheets remove organic compounds including chlorophyll and all other odor...

Details No Chiller Through the use of patent-pending diffusion condenser technology, the Yellowstone falling film evaporators have eliminated the need for expensive chiller systems, which are the most common restrictions of FFE...

The Yellowstone falling film evaporators are the most efficient on the market and are sold and serviced from our facility with real 24/7 service. The Yellowstone unit provides numerous efficiency-boosting features including...

ABM Equipment has been optimizing & integrating bulk biomass processing systems for over 40 years. ABM has implemented and researched bulk drying & handling solutions for producers and co-ops in the herb space since 1979.