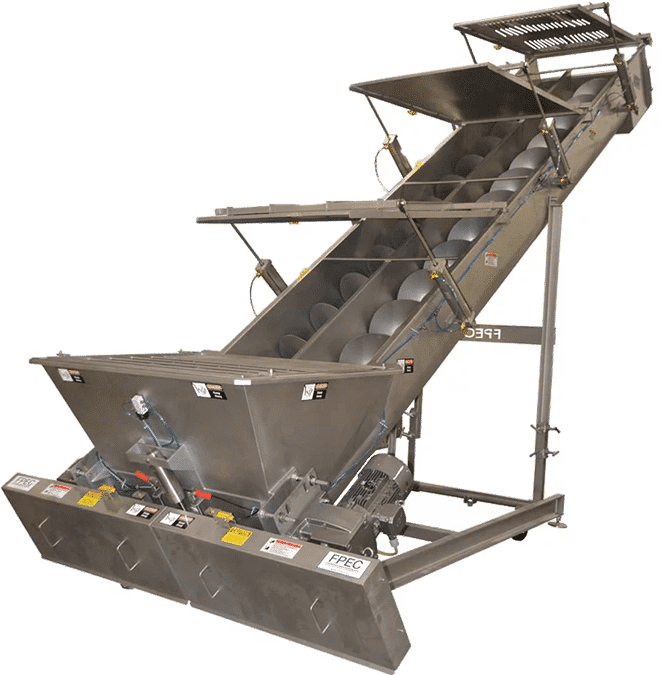

Screw conveyors are one of the oldest conveying methods known to man and still the ideal method for many applications. Though screw conveyors and augers are technically synonymous (any conveyance method driven by rotating...

Whole plant intake and storage to stalk removal and bagging of dried product, we can streamline any bulk material handling process. Browse the equipment or fill out the form below to learn about how we can scale your operations and reduce operating costs.

Screw conveyors are one of the oldest conveying methods known to man and still the ideal method for many applications. Though screw conveyors and augers are technically synonymous (any conveyance method driven by rotating...

Sizes Small Bud Sorter 24” diameter 2-Deck High Efficiency BudsorterOne 4” high top spacing frame with a 6” diameter oversize discharge spoutOne 4” high middle spacing frame with a 6” diameter product discharge spoutOne 6” high...

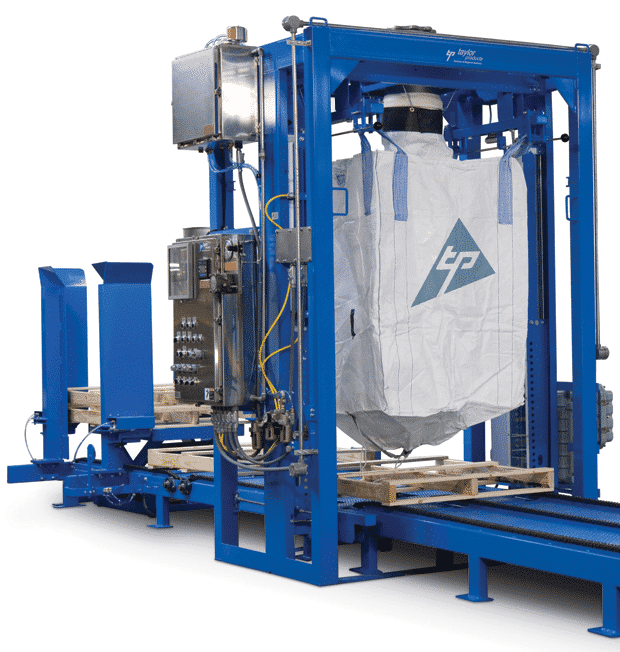

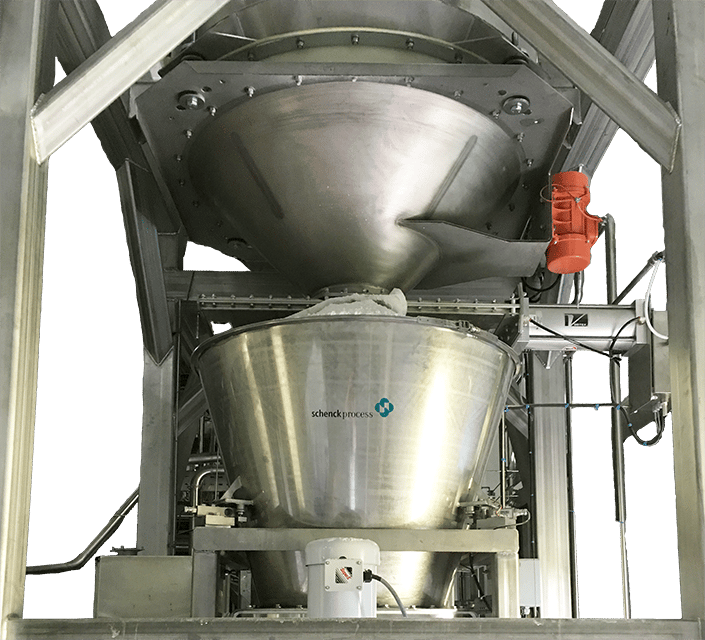

Bulk Bag Fillers, also known as super sack loaders, package product for sale or storage. Our Bulk Bag Fillers have numerous convenient features for longevity and ease-of-use, are backed with 24/7 emergency service, and can...

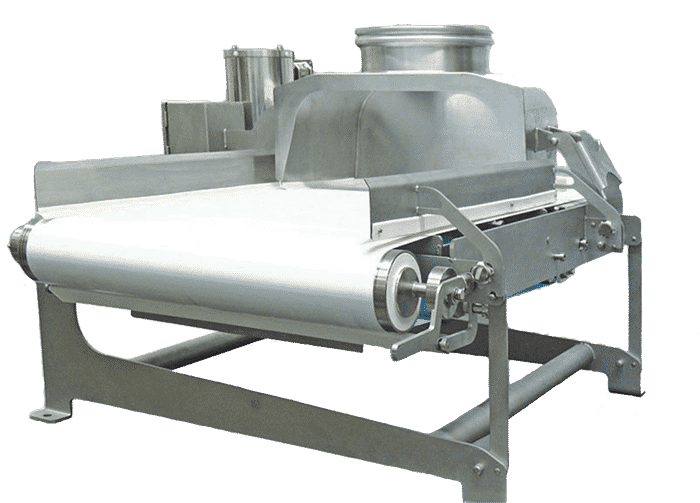

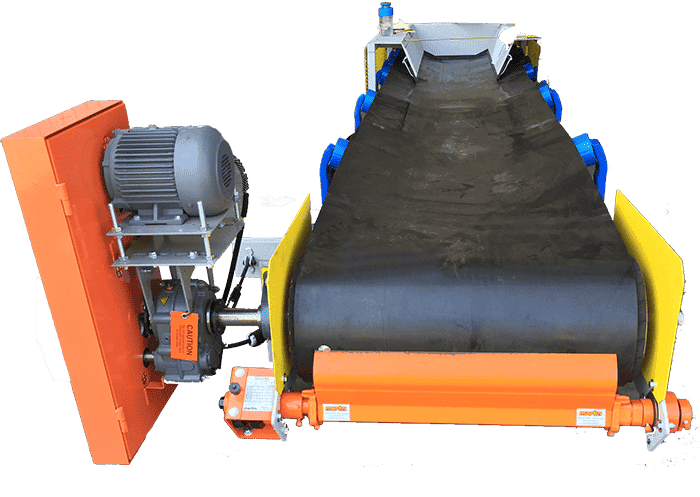

Weighbelts are flat belt conveyors with weighbars beneath the belt to measure product flow. Knowing product weight and convey-rate, weigh-belts precisely meter product into the dryer by communicating with up-stream equipment and...

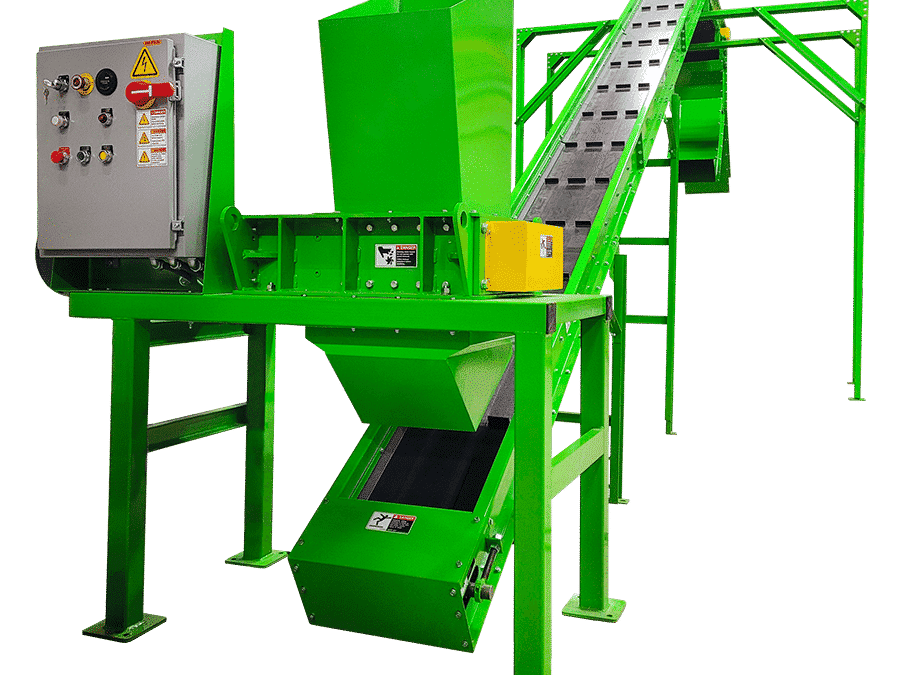

Shredders slice herb it into small, homogenized particle sizes in preparation for drying. Shredders are preferable over mills for wet product because mills crush instead of cut; crushing inflicts unnecessary damage, makes...

Herb Sifters separate stalks and stems from herb flower with far greater speed & precision than human hands, buckers, or other mechanical options. They are low-maintenance, easy to clean, and extremely long-lasting. Using...

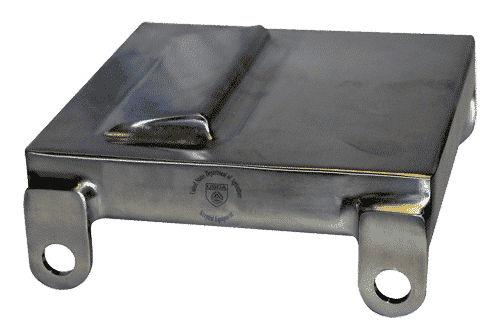

Magnets are a cheap and effective way to catch metals that may have been introduced to the field or the harvested bud. By passing herb across extremely strong magnets, metals that would otherwise damage the shredder and cause...

As with all equipment that touches herbs, even shredders, herb conveyors must be as gentle as practicality allows. A certain level of destruction is necessary for any competitive process, but reducing this effect whenever...

ABM Equipment has been optimizing & integrating bulk biomass processing systems for over 40 years. ABM has implemented and researched bulk drying & handling solutions for producers and co-ops in the hemp space since legalization.