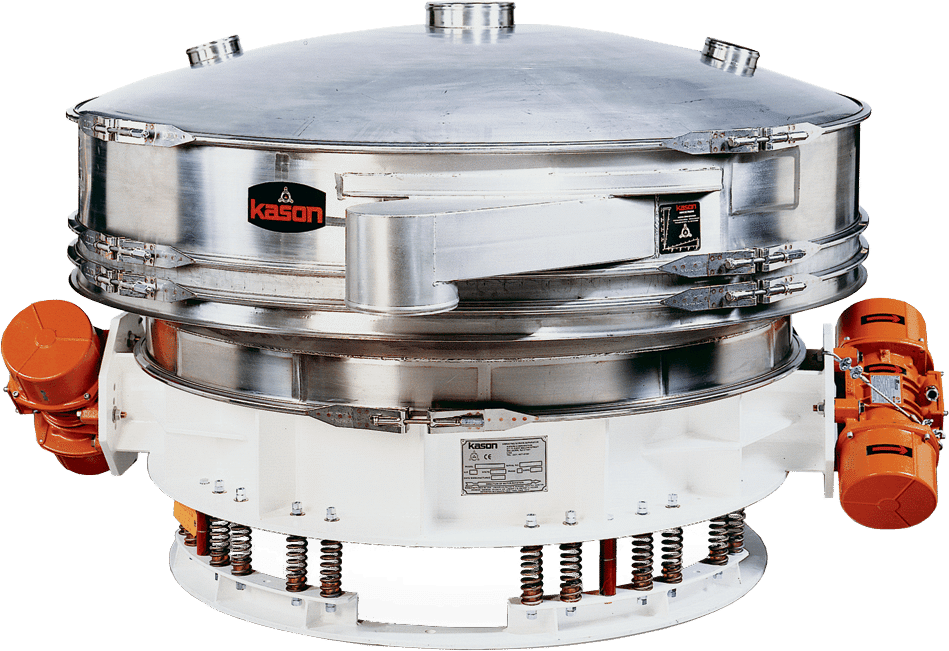

Dairy 3A Screeners

3-A sanitary vibratory screeners are the best option for removing impurities from milk, cream, cheese, and other dairy products because the vibration reduces pooling and allows more flow-through per square inch. Forced screening is not recommended as screen breakages are the second most common source of metal contaminants in dairy products (more on this in the Costco section below). As with most equipment we sell, these gap-free screeners have been optimized for the application and are available in sizes from 24 to 60 inches in diameter.

Designed to scalp oversize particles as small as 38 microns (400 mesh) from dry bulk materials or solids-laden slurries, this unit can be disassembled without any tools for rapid sanitizing. The interlocking flange of the screen frame completely encompasses the support ring of the screen, allowing the wire mesh of the screen to extend entirely to the interior walls of the frame, eliminating the gap found in conventional screeners where materials could accumulate.

The sanitary, gap-free design can eliminate contamination caused by bacterial growth while also improving sanitizing efficiency, making it suitable for food, dairy, and pharmaceutical products. The screens are mounted on support rings using FDA-approved epoxy and sealed with FDA-approved gasket material. They can also be provided with a mesh-tolerance certificate. The wire mesh screening material is available in 304, 316, and “magnetic” 400-series stainless steel that can be captured by a downstream magnet if broken. They can also be equipped with either single or twin imbalanced-weight gyratory motors and can be supplied with a dust-tight cover.

Low Profile Option

The low-profile option, also called a check-screener, uses two unbalanced-weight gyratory motors located on opposing exterior sidewalls instead of a single motor positioned below the screening chamber, which greatly reduces the minimum height requirement. This low-profile configuration allows on-size particles to pass quickly through the screen in a vertical discharge path at higher rates than circular screeners that have centrally mounted gyratory motors and horizontal discharge paths. Check-screeners do not have a discharge for sorting and is only for catching contaminants, so any contaminants/oversize material must be manually removed or eliminated using a vacuum.

A Word About Screeners and Costco’s X-Ray Exception

Although untrue, Costco believes that x-ray cannot find metals in dairy products, so they provided an exception in their universal x-ray requirements for suppliers. On these grounds they said dairy producers could use screeners instead of x-ray. If satisfying Costco’s requirements is your primary goal, these vibratory screeners are the safest to use. But if foreign material contamination is a high priority for you, we recommend using x-ray anyway, because broken screens are the largest cause of metal contaminants in dairy products, after mixers. If the cost of x-ray is prohibitive for your company, a cheaper precaution is to use a centrifugal sifter with a mesh screen. But either way, the mesh gap needs to be smaller than the maximum contaminant size.

If you have any questions or would like a quote, simply fill out the form below or give us a call!

Related Equipment

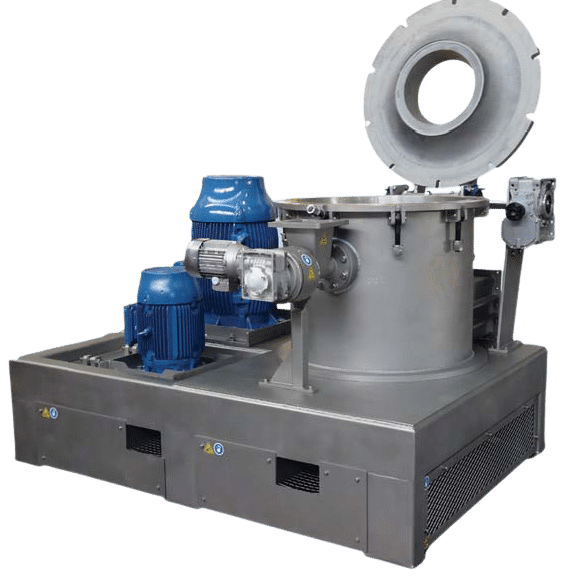

Air Classifiers

Our Air Classifiers mill product as finely as 5 μm and eject it when the desired size is reached. A type of vertical mill, Air Classifiers create the finest grinds possible. They accept product via augers or blowers and rotary valves, and mill it through grinding media and force against the grinding chamber walls. Configuration of the classifier and the grinding media can be easily swapped to get the best results for your product.

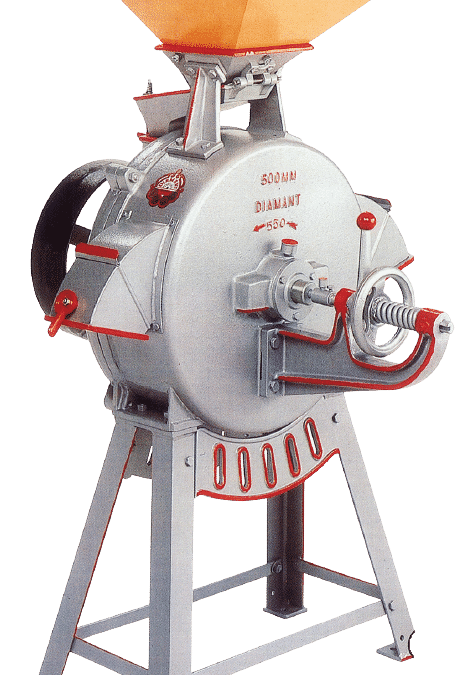

Tabletop Flour Mill

Most popular among grocery stores, bakeries, and farms, the Tabletop Flour Mill comes stock with a 9 lb. hopper. It can mill any product under 12% moisture and 6% oil, most commonly coffee, spices, and grains at up to 175 lbs. per hour depending on the desired fineness.

The tabletop mill is also available with a sifter which can be configured for flour, bran, and fine bran. It’s equipped with three separate outlets optimized for their respective flour types.

Spice Mill

First produced in 1910 and improved upon ever since, the Spice Mill is also ideal for small batches of grains, peas, and sugar. Mustard, coffee, and other oily products can also be ground efficiently with stones designed to handle the oils.

Get in touch to learn more about this mill and how we can automate or streamline your process.

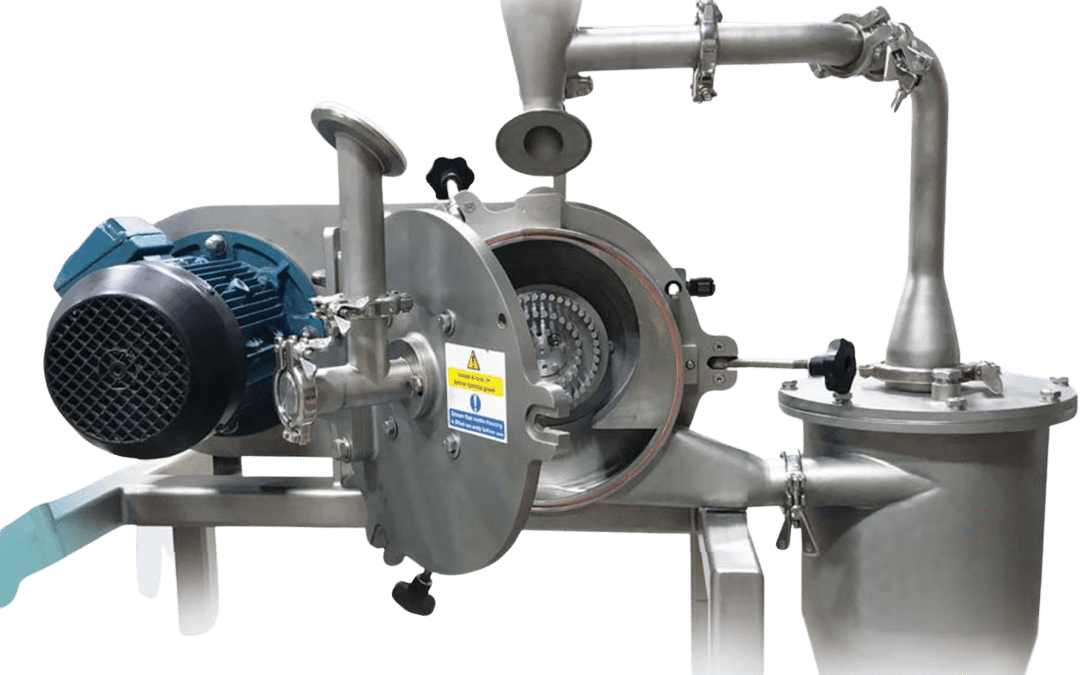

Universal Mills

Universal Mills, also known as combination mills, use multiple methods and configurations of those methods to deliver the broadest range of capabilities possible. They use turbine blades for a course grinds, a pin-mill configuration for fine grinds, and are compatible with various grinding media to fine-tune results. Both turbine and pin configurations can be utilized when incoming product is very course and outgoing needs to be very fine. It also protects product by using a closed-loop design (to prevent exchange of inside and outside air) and can optionally use low temperatures or inert gases for special cases, detailed under options. It’s compatible with most processing lines via flexible inlet and outlet configurations. The hinged doors allow for easy maintenance and inspection and it can reduce particle size to 100 μm – 20μm.