Sizes Small Bud Sorter 24” diameter 2-Deck High Efficiency BudsorterOne 4” high top spacing frame with a 6” diameter oversize discharge spoutOne 4” high middle spacing frame with a 6” diameter product discharge spoutOne 6” high...

Drying technique is often the single greatest determinant of end-product quality. Over-dried product will have low yield and under-dried product will mold. By controlling how varying strains and harvests enter the dryer, how they act within that dryer, and how they exit, we help growers consistently achieve the potency and vibrancy buyers want. We provide industry-best solutions, turn-key integration, and 24/7 service.

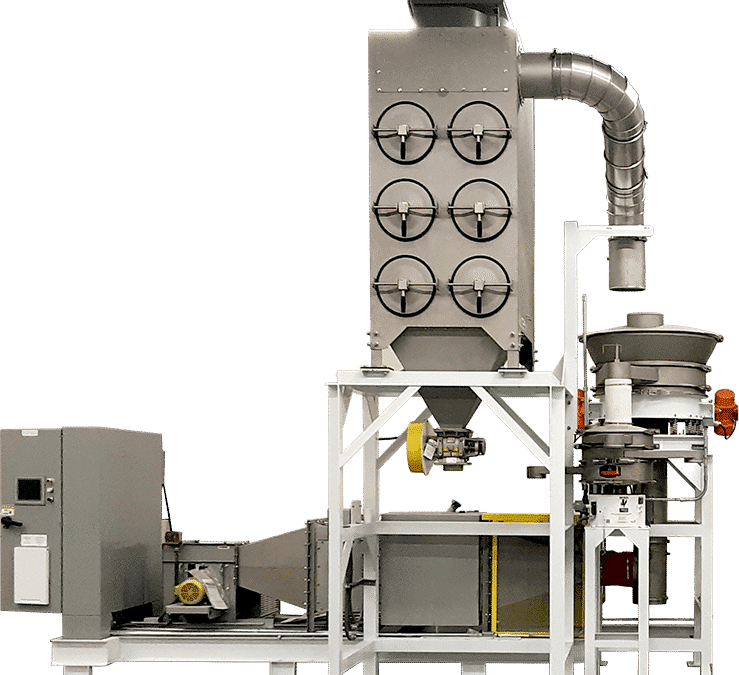

ABM’s circular fluid beds are the best solution for shredded hemp on the market. Using vibration and evenly-distributed airflow to suspend and fluidize hemp like ping-pongs ball over an airstream, heat is used as an aid rather than a primary driver of evaporation. This produces high yields and protects hemp’s natural green color. Single-stage systems dry up to 1,000 lbs/hr and dual stage up to 3,000 lbs/hr.

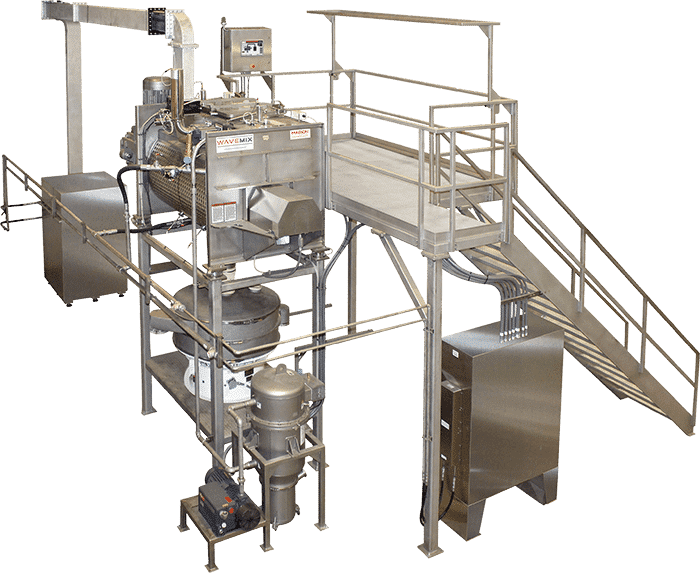

Microwave dryers’ air-tight vessels and temperature control are suitable for all forms of cannabis. They can be used to decarb pellets and gently dry pre-roll material because the specialized mixing paddles cause minimal product damage. System sizes are available from 60 to 400 cubic foot volumes for R&D and full production systems alike.

ABM’s circular fluid beds are the best solution for shredded biomass on the market. Using vibration and evenly-distributed airflow to suspend and fluidize hemp like ping-pongs ball over an airstream, heat is used as an aid rather than a primary driver of evaporation. This produces high yields and protects hemp’s natural green color. Single-stage systems dry up to 1,000 lbs/hr and dual stage up to 3,000 lbs/hr.

Microwave dryers’ air-tight vessels and temperature control are suitable for all forms of cannabis. They can be used to decarb pellets, extract terpenes, and gently dry pre-roll material because the specialized mixing paddles cause minimal product damage. System sizes are available from 60 to 400 cubic foot volumes for R&D and full production systems alike.

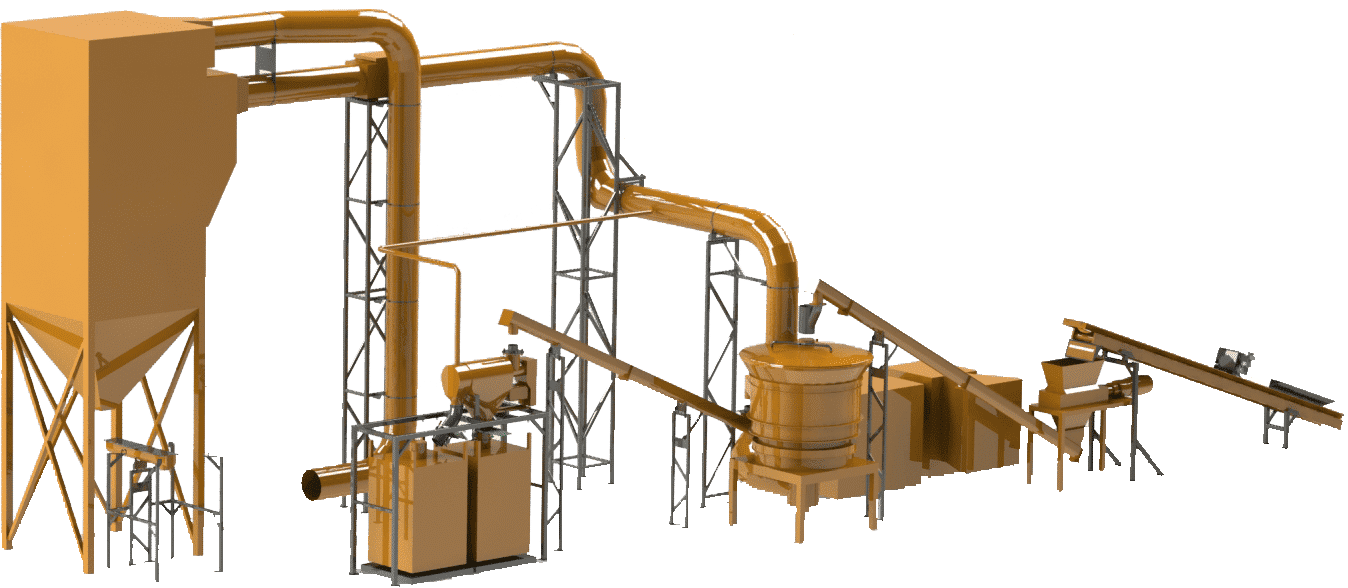

ABM delivers high-performing, turn-key systems that maximize spacial, budgetary, and legislative allowances. From stocky bushes to 8-ft trees, from cold and wet seasons to hot and dry, we deliver systems meant to perform under the variances you encounter season-to-season. We work with your team to create a system that maximizes your capabilites and support it throughout its lifetime.

Sizes Small Bud Sorter 24” diameter 2-Deck High Efficiency BudsorterOne 4” high top spacing frame with a 6” diameter oversize discharge spoutOne 4” high middle spacing frame with a 6” diameter product discharge spoutOne 6” high...

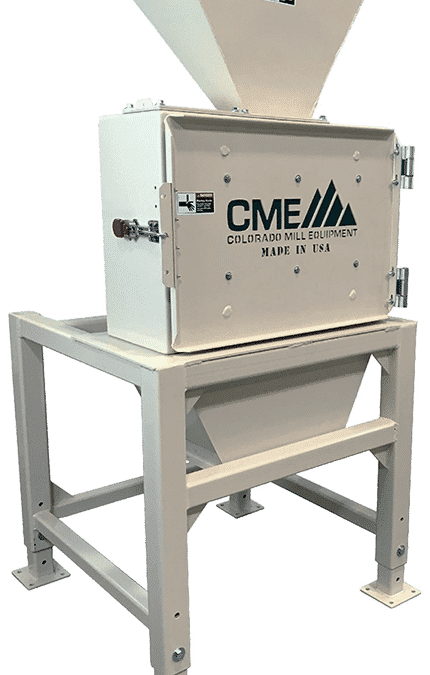

If bud isn't shredded finely enough for drying, mills are needed to reduce the particle size for primary extraction in order to achieve the best yields. (For particle size reduction before drying, see shredders instead). Because...

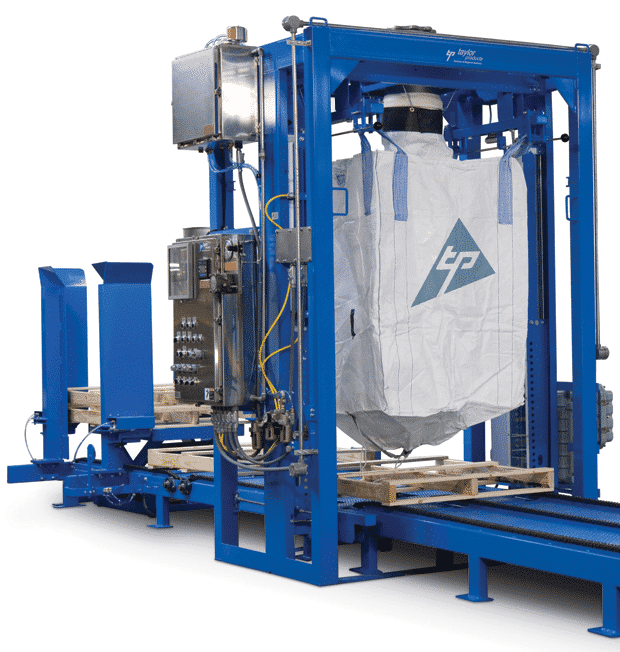

Bulk Bag Fillers, also known as super sack loaders, package product for sale or storage. Our Bulk Bag Fillers have numerous convenient features for longevity and ease-of-use, are backed with 24/7 emergency service, and can...

Herb Dryers use fluid beds to evenly distribute airflow to suspend and fluidize product, like ping-pongs ball over airstreams. Heat is used to improve performance, but because it is not the primary driver of evaporation, does...

When most people think of microwaves they think of indiscriminate radiation blasting, uneven heating, and hot bowls with cold food. But comparing consumer to commercial microwaves is like comparing a nuke to a nuclear reactor....

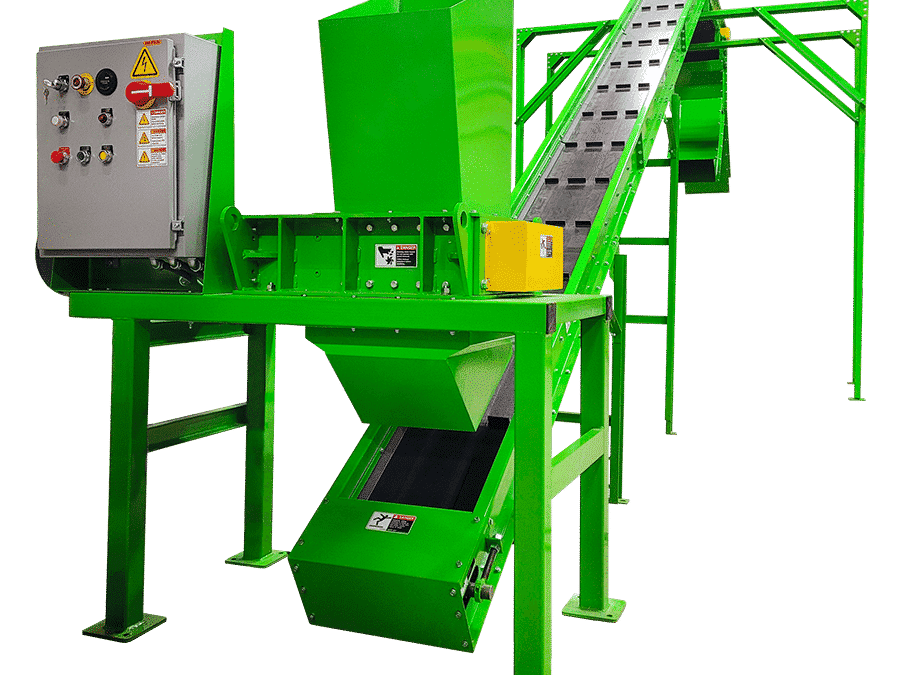

Shredders slice herb it into small, homogenized particle sizes in preparation for drying. Shredders are preferable over mills for wet product because mills crush instead of cut; crushing inflicts unnecessary damage, makes...

Herb Sifters separate stalks and stems from herb flower with far greater speed & precision than human hands, buckers, or other mechanical options. They are low-maintenance, easy to clean, and extremely long-lasting. Using...

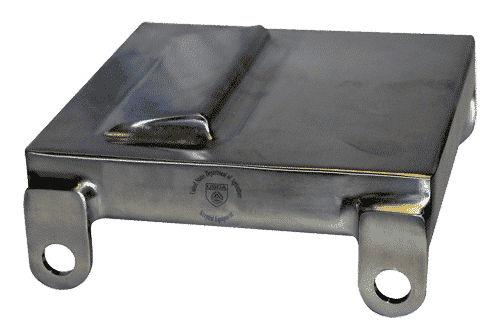

Magnets are a cheap and effective way to catch metals that may have been introduced to the field or the harvested bud. By passing herb across extremely strong magnets, metals that would otherwise damage the shredder and cause...

ABM Equipment has been optimizing & integrating bulk biomass processing systems for over 40 years. ABM has implemented and researched bulk drying & handling solutions for producers and co-ops in the herb space since 1978.