Brewery Augers

As with all of our brewery grain handling solutions, our flex and straight augers are supported with turn-key integration & 24/7 service.

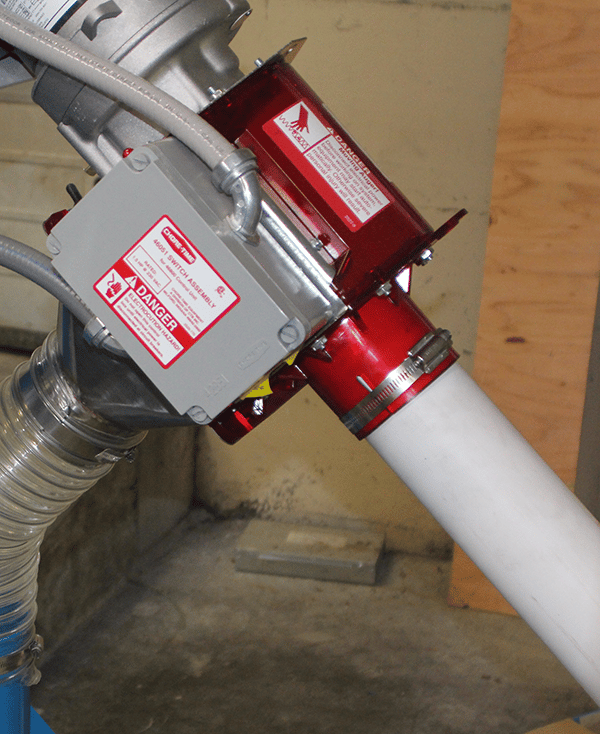

Augers employ screw-shafts to convey malt through PVC tubing and are ideal for small breweries and short runs. The entry-point is lower for augers than for chain-disks, but they’re generally not good long-term solutions. They’re rough on product*, create runoff**, and have a couple other limiting factors.

First, flex augers can only manage 45° inclines. They can be pushed to 60° in a pinch but this sacrifices speed and increases runoff. Second, every 45° slope change requires a 5ft radius and this consumes a lot of space. Third, the sharper the turn, the more the pipe is rubbed by the shaft and the sooner it needs to be replaced. Tubing generally lasts 1-3 years, and motors over 5. Augers can last up to 5 years if never run dry, but this is hard to do.

Conveying Rates (0° – 45° incline)

Rates will decrease as you increase the incline because of the load on the motor, but the change is not drastic until you go past 45 degrees, at which point the grain will begin to fall back, or “run off”.

3″ Diameter

Whole grain – 42.5 lbs /min (at 34 lbs/ft³)

Milled grain – 31.5 lbs /min (at 25 lbs/ft³)

3.5″ Diameter

Whole grain – 85 lbs /min (at 34 lbs/ft³)

Milled grain – 62.5 lbs /min (at 25 lbs/ft³)

4.5″ Diameter

Whole grain – 187 lbs /min (at 34 lbs/ft³)

Milled grain – 137 lbs /min (at 25 lbs/ft³)

*High friction between the shaft and the grain creates a lot of fines that impede lautering and can cause off-flavors.

**Steep slopes allow grain to fall through the hollow shaft. This lowers the conveying rate and sometimes causes product to fall all the way back into the mill and be re-ground.