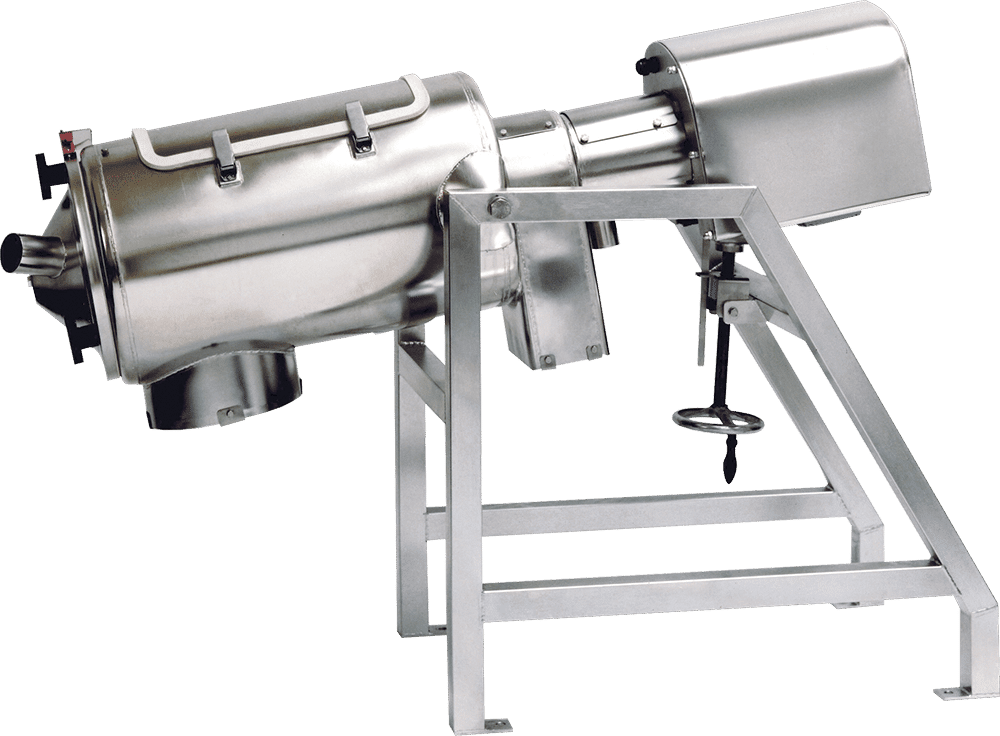

Spent Grain Dewatering Centrifuges

Cost-Effective & Efficient

The most effective spent grain dewatering centrifuges on the market for off-the-grain distilling and wastewater removal

Effective

Reduces up to 90% of moisture at up to 100 GPM

Efficient

Cleans up/reduces waste stream, improves dryer efficiency, preserves grain

Convenient

Motor above the centrifuge, fully-englosed design, infinite turn-down ratio

Simple

Easy setup, one-man and toolless operation and breakdown

Efficiently dewatering spent grain has long been a problem for distillers (especially those in Kentucky who produce roughly 95% of the world’s bourbon). Through years of trial and error, however, centrifugal sifters have emerged as the best modern solution, with a specific configuration—dubbed the dewatering centrifuge—leading the pack. Whether dewatering spent grain for distillation, drying, disposing, or giving to farmers, we’re proud to offer the best combination of painless, efficient, and cost-effective on the market.

Details

• Flow rates up to 100 gal/min

• Reduces moisture content to as low as 65%

Features

• Convenient Design

• Small footprint

• Quick, simple setup

• 1-man operation, assembly, and breakdown

• Completely enclosed

• Motor above the chamber

• Very low turn-down ratio

• Spray bars to avoid oversized particles in the mesh

• Combustion proof motors for utmost safety

• Variety of finishes for all applications

• Adjustable speed for fine tuning separation needs

Benefits

REDUCED COSTS

• Reduce disposal costs (positive ROI within 3 months for larger distilleries)

• Reduced operation costs

IMPROVED EFFICIENTY

• Reduces cycle time with fast operation

• Minimizes maintenance with self-cleaning design

SIMPLE OPERATION

• Completely enclosed and easy to operate

• First setup within hours

• Toolless breakdown and cleaning

• Clean up waste streams

Operation

• Liquid is either gravity fed or pumped into the inlet at the lower end of the machine. From there it passes into a cylindrical mesh basket where a rotating paddle assembly separates liquids from solids by way of centrifugal force.

• The retained solids agglomerate inside the mesh basket and are moved to the oversize outlet by a helical scroll on the paddle blade assembly.

• Throughput and the degree of dryness of the solids can be controlled with the optional variable speed gearbox and the tilt angle adjustment of the separator body.

The dewatering centrifuge is a unique, proven technology utilized in many industries across the world.

When Do I need one?

Depending on your labor cost, spent grain dewatering centrifuges will start paying for themselves when you’re emptying 800-1000 gallon tanks 3-5 times per week.

Reasons distillers need to dewater their spent grain

The #1 reason brewers and distillers dewater their spent grain is because they’re required to by their city. This is because large volumes of organic solids can 1, disrupt the biological methods used to treat wastewater and 2, become an oxygen-sink that kills marine life.

But even if you’re not required to dewater, it’s an overall beneficial process whether you upcycle or throw it away. If spent grain is treated as waste, dewatering reduces most of the weight, and thus disposal cost. If it’s upcycled, dewatering vastly improves dryer efficiency. If you’re dewatering for distillation, using a dewatering centrifuge will yield the most fluid without crushing bitters into the wort. (Dewatering centrifuges are sometimes called de-sludgers because they can be used for corn with varying levels of efficiency depending on how homogenous the slurry is.)

Why this solution is the best on the market

Our Dewatering Centrifuge

• Easy cleaning with a tool-less single unit disassembly

• Controlled noise (85 decibels)

• Optimal design that prevents water from leaking into the motor

Next-Best Solution

• Less convenient disassembly

• Louder operation

• Design that results in water leaking into the motor

Whether dewatering for yourself, the city, or the environment, tell us about your project so we can get you the best-available solution!