Herb Sifters

Herb Sifters separate stalks and stems from herb flower with far greater speed & precision than human hands, buckers, or other mechanical options. They are low-maintenance, easy to clean, and extremely long-lasting.

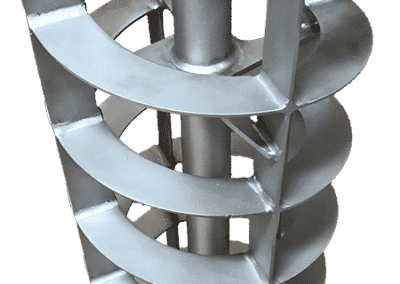

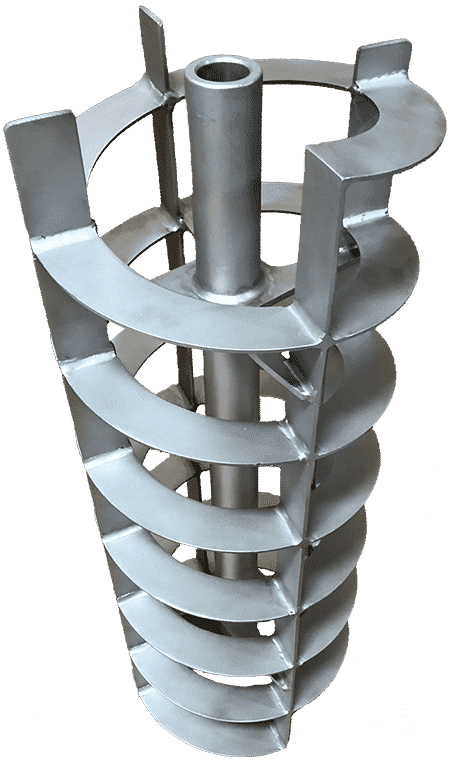

Using flow-assists and screw feeders to control the flow of shredded bud into the separating chamber, it uses specially-shaped paddles to propel it against the surrounding sieve. This pushes the desirable fines out through the apertures while the over-sized stems are rejected.

The two main solutions for de-stemming whole plants entail either hand-feeding small machines stalk-by-stalk, or gleaning buds imprecisely at harvest. But if the biomass is purposed for extraction, our sifters can remove stems from product after shredding with near-perfect precision at up to 3,000 lbs/hr/unit. The effectiveness of this method is demonstrated in the first image of the gallery.

In the ABM Drying Systems, herb sifters are placed after the primary dryer and before bulk bag fillers to remove the fibrous material. Because these finer materials are often too light to be separated using sorters, centrifugal force is used to draw the coarse product toward the walls of the unit while the premium product is pneumatically floated through the center out the other discharge. ABM offers turn-key integration, fine-tuning, and full support for all of our equipment and sometimes others’.

These herb sifters from Kason are extremely tough, reliable, and come with several options for varying product properties. They operate by feeding the bud into porous metal cylinders with rotating helical paddles, which scoop the unwanted product outward and through the pores while the flower is ejected from the end of the cylinder. The discharges which can be fitted with manual or automatic valves into the surge hoppers. These centrifugal sifters boast incredible longevity, are reliable and low-maintenance, and can be fitted with various different screens configurations for use with alternating strains and shredder settings. They are rated for pressures up to 14.7 psig (1 barg) and are capable of handling as much product as our dryers can feed them. The thoroughly-engineered design and components facilitate easy cleaning, but the units can optionally come clean-in-place.