Equipment & Systems

For handling, processing, packaging, & inspection

A full-service sales, engineering, and integration group with 40+ years’ experience across hundreds of applications and industries.

Equipment & Systems

For Bulk Dry handling, processing, packaging, & inspection

Food, pharma, nutra, chemical, aggregate

Individual components to complete, integrated systems, ABM Equipment scales processes from concept to completion. From product testing to maintenance 10 years down the road, we are a single point of responsibility with in-house engineering, fabrication, & service.

Equipment Sales

OEM SALES

- Manufacturer Model Selection

- Cost

- Quality

- Features

- Support & Resources

CUSTOM-BUILT EQUIPMENT

- Vessels, Transitions, & Structures

- OEM Alterations

Process Engineering

- Block Flow

- P&ID

- Functional Description

- Equipment Sizing

- Process Control

- Site Plans/Final Drawings

Product Testing

- On-Site/In-House

- Raw Materials Testing

- Performance Testing

- Process Control

- Compliance Verification

- Product Development

Mechanical Engineering

NEW EQUIPMENT DESIGN

- New models for OEMs

- Vessels

- Structures

- Transitions

- Custom Pieces As Required

EXISTING EQUIPMENT OPTIMIZATION

- Vessels

- Transitions

- Structures

- Retrofits and upgrades

Fabrication

CUSTOM EQUIPMENT

- Vessels

- Structures

- Retrofits and upgrades

EQUIPMENT MODIFICATION

- Functional Optimization

- Inlet/Outlet Configuration

SYSTEM INTEGRATION

- Equipment Installs & Configuration

- Transitions

- Walkways & Industrial Structures

General Contracting

CODES & ORDINANCES

- Review

- Consultation

- Compliance & Workarounds

CONSTRUCTION MANAGEMENT

- Subcontractor Selection

- Subcontractor Management

- Supervision

- Inspection

- Site Management

- Scheduling

- Resource Tracking

- Cleanup

- Safety

- Demolition

Service

COMMISSIONING

- Functional Testing

- Integration Testing

- Calibration

TRAINING

- System Flow

- Operation

- Documentation & SOPs

- Maintenance

Maintenance & Repair

- Service Contracts

- 24/7 Phone Support

Software

Our flagship suite, DSO Sentinel, reports on your entire processing line (with the ability to control it) and automates many steps of the buyer audit process. DSO Sentinel fulfills Costco requirements for product traceability, machine validation records, and others.

- Automated reports

- Remote alerts (SMS and email)

- Settings change tracking

- Rework-assist functions

- X-ray image recall

- System control (custom configuration)

- Product tracing

- Much more

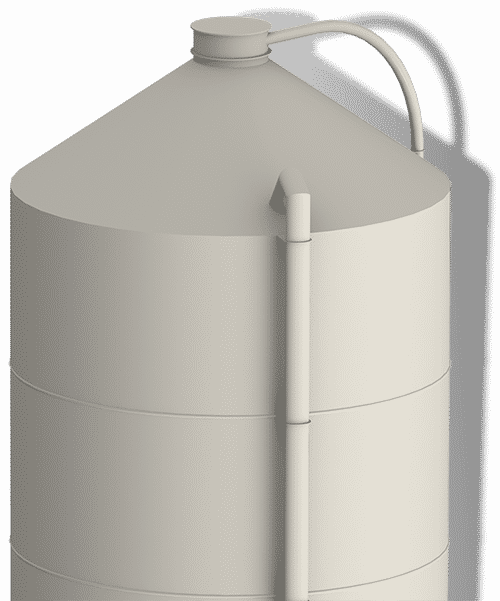

Handling Equipment

Conveyors, Feeders, and Product Intake & Storage

Homogeneous slurry or caking blend, every product has a way it likes to be moved and stored. Whether your best solution exists out-of-the-box or in a unique blend of equipment built from scratch, we’ll deliver a system that optimizes your project’s ROI.

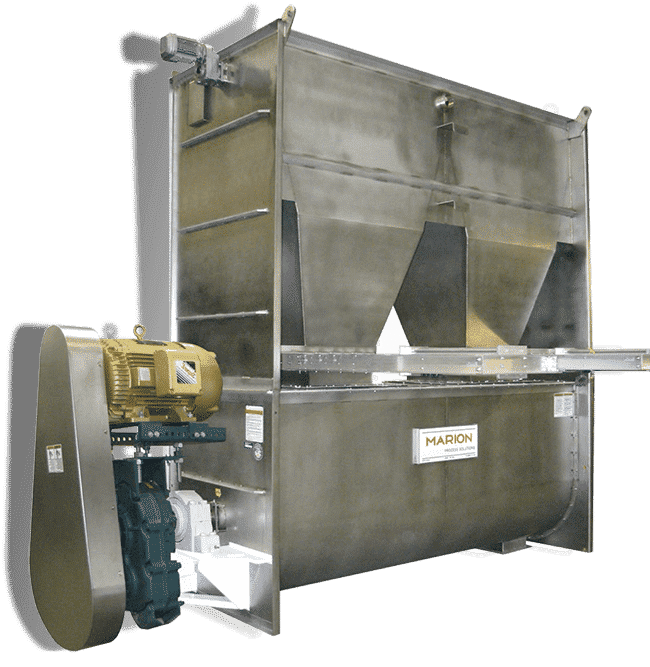

Processing Equipment

Blenders & Mixers, Mills, Classifiers, Feeders, etc.

Our oldest area of expertise, the processing umbrella includes equipment needed to mix, separate, and alter products: milling, blending/mixing, particle size reduction, filtration, sifting, dust collection, process controls, and volumetric and gravimetric weighers and feeders.

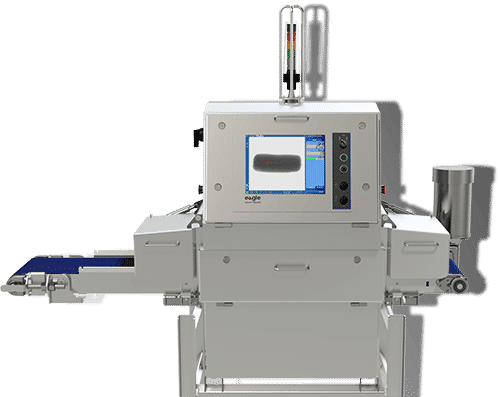

Inspection Equipment

X-Ray Machines, Checkweighers, and Metal Detectors

Product inspection receives the bulk of our R&D budget. We source, modify, and integrate metal detectors, checkweighers, samplers, magnetic systems, moisture analyzers, lipid analyzers, PH monitors, and x-ray machines. We have over 30 x-ray machines in stock for rentals, demonstrations, and training.

Packaging Equipment

Palletizers, Placers, and Fillers for Bags, Pouches, Drums, Boxes, & Totes.

We package various classes of product and can integrate nearly any system. We most commonly deal in bulk weighing automations; open-mouth and pouch bagging equipment, line accessories, and shaping, filling, and sealing.

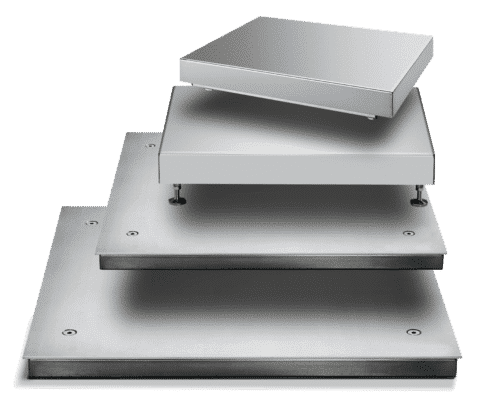

A-1 Scales

Lab scales to heavy industrial, sales to installation & repair

ABM Equipment’s weighing division, A-1 Scale, is the Portland Metro area’s primary scale and calibration provider for all types of professional scales, from nanograms to tons. A-1 Scale handles our complex weighing applications and ensures accuracy and precision of our weighing and batching systems.

Contact Us

Need Equipment?

Tell us about your product, where it’s coming from and where it’s going, and what you’re trying to accomplish; we’ll get you a quote in no time.

Need A System?

Tell us about your product, how you’re currently making it, and any unique challenges of your application. We’ll have a few more questions but will get you a quote all the same!

No Solicitations

If you have an offer, email us.

"*" indicates required fields

Address

13911 NW 3rd Ct.

Vancouver, WA 98685

Phone

SALES – (503) 248-0711

SERVICE – (360) 558-7156

Office

contact@abmequipment.com

M-F: 8am – 5pm