Cartridge Dust Collectors

Cartridge dust collectors use pleated filters, like those in your car and home, to filter small particulates out of the air of manufacturing facilities. The filters can be round or rectangular, and made of natural or synthetic materials depending on the application. Most cartridge dust collectors come with a pulsating jet function, which reverses the air in the system to self-clean the filters and improve efficiency and lifespan.

As compared to cyclones and baghouses, cartridge dust collectors take up less space, trap more dust, and are easier to maintain, but the filters cannot handle as much debris and are therefore not suitable for high-volume applications.

Below you will find a table with different popular models we carry in each tab, followed by more general information about cartridge dust collectors like components, benefits, considerations to make when choosing, and maintenance advice.

If this is too much information, don’t hesitate to reach out via the form below or give us a call. We can help.

The Mac2Flo is an efficient and cost-effective solution for the filtration of fine submicron dusts in large applications. Its unique design allows for dust-laden air to enter the top of the filter and flow downward, effectively settling even the finest and lightest dusts. With up to 23.5m² of media per filter cartridge, it offers significant filtration potential within a compact housing. Its modular design allows for easy expansion and reduced initial capital costs. The tool-free cartridge removal system also reduces ongoing maintenance costs.

Operating Principle

The Mac2Flo cartridge dust collector provides efficient filtration with a high volume of airflow, thanks to its large square footage of media per cartridge. The unique design of the filter allows for dust-laden air to enter from the top and flow downwards, resulting in more effective settling of fine, light dusts. The compact housing can hold up to 144 cartridges and its modular design allows for easy expansion as needed. The mini Mac2Flo is also available in smaller configurations of 1, 2, or 3 cartridges and includes an integrated fan.

Features

- Multiple inlet/outlet locations

- Tool-free cartridge removal

- Timer in Nema 4 enclosure

- Guaranteed outlet emission levels

- Ultra high efficiency MEGABond™ nanofiber cartridges

Options

- Explosion venting

- Abrasion resistant inlets

- Stainless steel construction

- Rotary valves

- Slide gate/drum cover kits

- Inlet collars

- Integral fan packages

- Bag-in/bag-out cartridge access

- Platform and ladder

- Electrical control panels

- Screw conveyors

Benefits

The Mac2Flo’s compact design and reduced compressed air requirements save energy and floor space. The Mac2Flo features the latest nanofiber technology, MEGABond filter cartridge media, which delivers HEPA efficiencies for a wide variety of dust collection applications, resulting in superior mechanical strength and extreme durability with increased surface dust loading, fractional efficiency, and better dust holding capacity. The Mac2Flo is available with 1-16 filtration units with a wide selection of media options.

The ProTura media maintains filtration efficiency on 2-micron material after 350 hours of testing. The modular design reduces initial capital cost and makes future expansion easy, tool-free cartridge removal reduces ongoing maintenance costs, reduced setup time lowers installation costs, reduced compressed air requirements save energy, and interchangeable components help lower inventory costs.

Applications

Typical applications include steel making fume/dust, MCC room filtration, pre-filters for large motors, weld fumes, and assay labs. The Mac2Flo is designed to handle light dust loads and high volume of air flow, such as collecting extremely fine particulate like weld smoke, laser cutting particles, and fumed silica, with an initial efficiency of 99.99% on 0.5 micron and larger particles.

The SpaceSaver Dust Collector is a compact and efficient filter designed for spaces with limited footprint or headroom. It is perfect for areas not easily connected to central dust collection systems. The SpaceSaver Dust Collector can handle a range of air volumes from 850 to 25,000 m³/hr, depending on the dust type and number of modules used. The cartridges are oval-shaped and have a narrow pleat design, allowing for a maximum of 10m² of media to be packed into a small cartridge, ensuring that the filter remains as compact as possible.

Features

- The patented cleaning mechanism of the dust collector uses directed airflow to thoroughly pulse the cartridges, saving energy and extending the cartridge life.

- Maintenance is made easy with the tool-free cartridge changing system and the unique blowpipe configuration reduces maintenance time even further.

- Quick release handles allow for fast and effortless removal of the entire pipe section.

Operating Principle

The SpaceSaver Dust Collector is designed to meet the specific needs of customers with limited space, vertical clearance, and areas that are not easily connected to central dust collection systems. Its compact size eliminates the need for confined space entry. The self-contained dust collection system utilizes a patented cleaning mechanism that thoroughly pulses the cartridges using directed airflow, resulting in energy savings and longer cartridge life. The maintenance is completely tool-free for changing the cartridges and the unique blowpipe configuration also reduces maintenance time. With quick release handles, the entire pipe section can be easily removed. And of course, the SpaceSaver Dust Collector is engineered to meet NFPA compliance.

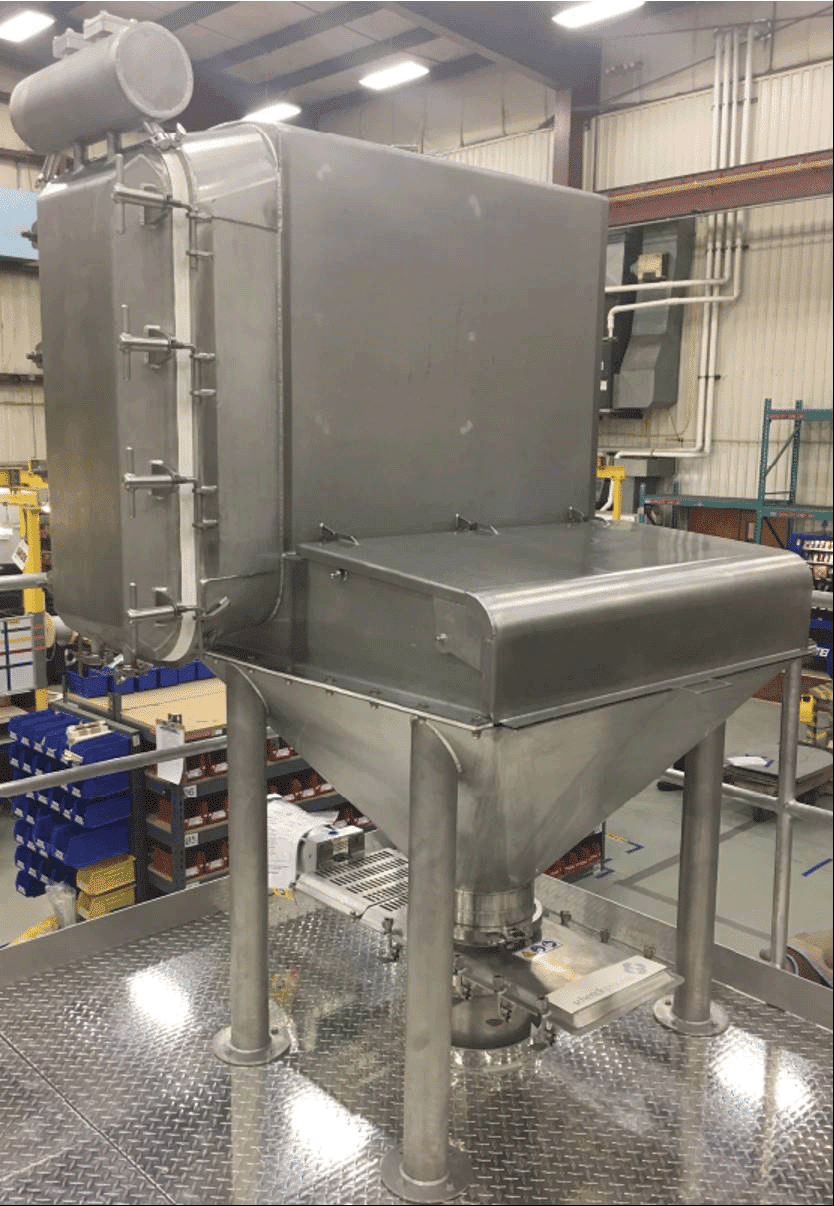

The VCF dust collector is a versatile and efficient solution for the collection of dust and other particulate matter from industrial processes. The VCF (Vertical Cartridge Filter) dust collector is designed to handle low to medium air volumes and can be used in a wide range of applications, including welding, grinding, and sanding.

One of the key features of the VCF dust collector from Schenck is its compact design. With a smaller footprint than traditional baghouse dust collectors, the VCF can be installed in tight spaces and areas with limited headroom. This makes it an ideal solution for retrofitting existing facilities and for new construction projects where space is a concern.

The VCF dust collector is also known for its easy maintenance. The filter cartridges are easy to remove and replace, and the unit is designed to minimize downtime. The filter cartridges can be replaced without the need for tools, which makes the process faster and more efficient. Additionally, the filter cartridges are designed to last longer, which reduces the need for frequent replacement and lowers overall maintenance costs.

One of the main benefits of the Schenck VCF dust collector is its high efficiency. The vertical design of the filter cartridges allows for maximum use of the filter media, and the pulse-jet cleaning system ensures that the filter remains clean and efficient at all times. The dust collector is also designed to minimize pressure drop, which helps to reduce energy consumption and lower operating costs.

The Schenck VCF dust collector is available in a range of sizes, making it suitable for a wide range of air volumes. The unit can be configured with multiple filter cartridges to increase filtration area and provide even greater efficiency. The dust collector can also be customized to meet specific application requirements, such as high temperatures or corrosive environments.

The Schenck VCF dust collector is also known for its safety features. The unit is designed to be explosion-proof, which makes it suitable for use in potentially explosive environments. Additionally, the dust collector is designed to minimize the risk of fire and has been tested to ensure compliance with relevant safety standards.

About Cartridge Dust Collectors

Components

The main components of a cartridge dust collection system include the blower, the filter housing, and the cartridges themselves. The blower creates the suction that pulls dirty air into the system, while the filter housing contains the cartridges and controls the flow of air through them. The cartridges are made of a porous material, such as polyester or fiberglass, that captures dust and other particles as air flows through them.

Common Filter Materials & Their Applications

- Cellulose: Cellulose filters are made from natural fibers such as cotton or wood pulp. They are inexpensive and have a good dust holding capacity, making them well suited for removing coarse particles. They are commonly used in woodworking and other industries where the dust particles are large and visible.

- Synthetic: Synthetic filters are made from synthetic fibers such as polypropylene or polyester. They are more durable than cellulose filters and can withstand higher temperatures and humidity. They are also resistant to chemicals, making them suitable for use in chemical processing and other industries where the dust particles are small and fine.

- Nanofiber: Nanofiber filters are made from ultra-fine fibers, which are smaller than 1 micron in diameter. They have a very high dust holding capacity, making them well suited for removing fine particles. They are commonly used in pharmaceuticals, food processing, and other industries where the dust particles are very small and can be harmful if inhaled.

- Activated Carbon: Activated carbon filters are made from carbon that has been treated with oxygen to open up millions of tiny pores between the carbon atoms. These filters are used to remove odors, volatile organic compounds (VOCs), and other gases. They are commonly used in industries where the dust particles contain harmful chemicals or gases.

Benefits

One of the major benefits of cartridge dust collection systems is their high efficiency in removing dust and other particulate matter from the air. Because the cartridges are made of a porous material, they are able to trap and remove a wide range of particle sizes, from fine dust to larger particles. This makes them well-suited for use in a variety of industrial and commercial environments, including woodworking shops, metalworking shops, and food processing facilities.

Another benefit of cartridge dust collection systems is their relatively low maintenance requirements. Unlike other types of dust collection systems, such as baghouses, cartridges are easy to replace and clean. This can help to minimize downtime and keep the system running smoothly.

Maintenance

To ensure that your cartridge dust collection system is operating at its best, it is important to properly maintain the cartridges. This includes regularly inspecting the cartridges for signs of wear or damage, and replacing them as needed. It is also important to clean the cartridges on a regular basis, using a vacuum or compressed air to remove any dust or debris that has accumulated on the surface of the cartridges.

In addition to maintaining the cartridges, it is also important to keep the blower and filter housing clean. This can be done by using a vacuum or compressed air to remove any dust or debris that has accumulated in these components. It is also important to check the filter housing for any signs of damage or wear, and to replace any worn or damaged parts as needed.

Considerations

When choosing a cartridge dust collection system, there are several factors to consider. One important consideration is the size of the system, which will depend on the size of the area that needs to be cleaned and the type and volume of dust or particles that are being removed. It is also important to choose a system with a high air flow rate and filter area, which will help to ensure that the system is able to effectively remove dust and other particulate matter from the air.

Another important consideration is the type of cartridges that are used in the system. Different types of cartridges, such as polyester or fiberglass, are better suited for different types of dust or particles.