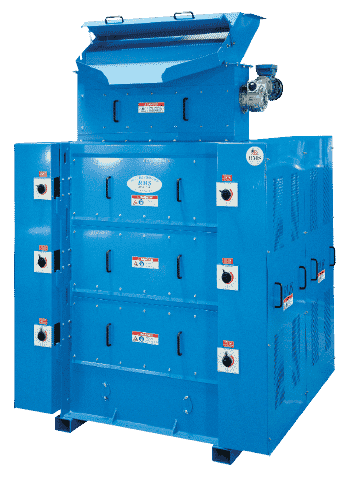

Roller Mills

Roller mills use cylindrical, opposing rollers to crush or grind material that is fed between them. They are used for medium to coarse grinding where control is key, and are capable of producing a wide range of particle sizes. Roller mills are suitable for grinding materials that are relatively soft and not too abrasive, such as grains, seeds, and certain types of food products. They are also useful for gentle, consistent applications like cracking grain. They are not used for extremely hard materials because they can knock the rollers out of tuning and cause loss of efficiency and constant adjustment.

Operating Principle

Roller mills consist of a series of rollers that are mounted on a frame, spinning on bearings. The material to be processed is fed into the roller mill, and as the rollers rotate, they crush or grind the material into smaller particles. If the particles are inconsistent or large and need to be made very small, a series of rollers are used to step down the material bit-by-bit.

The grind size is set by adjusting the gap between the rollers. This is done by turning a screw or lever that moves the rollers closer together or farther apart. By adjusting the gap, the roller mill can produce a wider range of particle sizes, from fine to coarse feed. More expensive models can have their rollers adjusted remotely.

The consistency of grind is determined by the manufacturing quality and the number of rollers the material passes by. Higher quality mills will be sturdier, making the roller position more consistent, thus a more consistent grind. And more rollers means more passes of the product, which always reduces variability. Though there is an exchange between these two strategies, increased rollers will be more effective and more expensive.

Types of roller mills

There are several types of roller mills including standard roll crushers, smooth roll crushers, and toothed roll crushers. Standard roll crushers have a simple design and are commonly used for primary crushing applications. Smooth roll crushers are usually more complex and are used for finer applications. Toothed roll crushers have serrated teeth on the rollers and are used for breaking down sticky materials.

Advantages

Roller mills have several advantages over other types of milling equipment.

- Produce minimal fines (useless particulates/dust)

- Versatile, able to crush a wide variety of materials.

- Easy to maintain and operate (relatively), making them a popular choice for many industrial and commercial applications with varying products.

- Gentle (able to crush to specific sizes and no more)

- Low heat (relatively)

Disadvantages

Roller mills are not able to process as much material as other types of mills per square foot of equipment.

Cheaper roller mills can seem to produce a lot of noise or dust, but will still probably be quieter than another type of mill would be. Even with a cheap mill, both can be mitigated by enclosing the mill in a “milling room” and using dust collection. This is typically the preferred solution by municipalities because they don’t understand that roller mills don’t produce dust fine enough to explode in many applications, but if they are open to reason, the dust can also be eliminated by using a dust-tight mill with dust-tight ports. This is an integrator-specific solution you should inquire about if interested.

Another potential disadvantage of roller mills is that they may not be as effective at grinding or crushing materials that are extremely hard or moist.

Finally, roller mills are not suitable for what are generally considered fine grinds.

Uses

Roller mills can be used in a variety of settings including flour mills, feed mills, chemical processing, mineral processing, and breweries. For applications with sticky material, rollers with teeth can be integrated.

Roller mills are often used in combination with other equipment to further process the material. For example, in a flour mill, the material produced by the roller mill may be passed through a sifter to separate the different types of flour. In a feed mill, the material produced by the roller mill may be mixed with other ingredients to create a complete feed for livestock.

In summary, roller mills have several advantages, including efficiency, versatility, easy maintenance, durability, and cost-effectiveness. These advantages make them a popular choice for many industrial and commercial applications.