Microwave Dryers

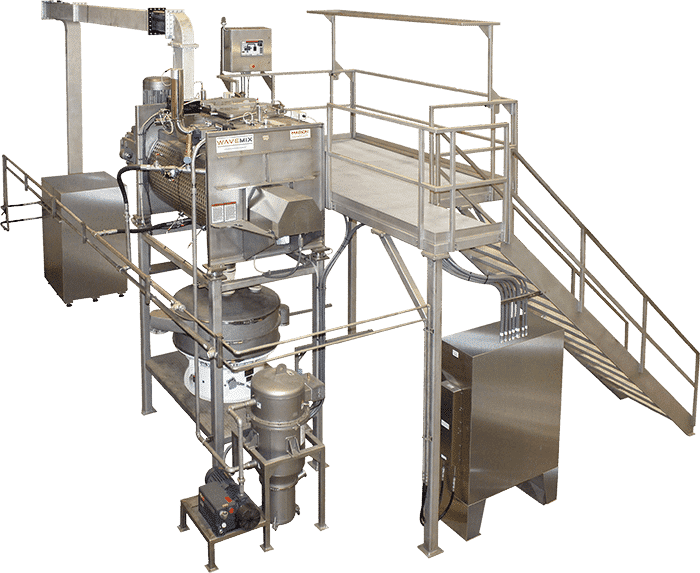

When most people think of microwaves they think of indiscriminate radiation blasting, uneven heating, and hot bowls with cold food. But comparing consumer to commercial microwaves is like comparing a nuke to a nuclear reactor. The Marion WaveMixe uses vacuum to reduce the moisture’s boiling point and tightly controlled microwaves to hold product, to the exact desired temperature within less than 1°F variance. This has the primary benefit of allowing us to ensure virtually no loss of herb extract, and the secondary benefit of being able to decarboxylate pellets.

Because these mixers retains over 99% of herb extract content and the specially-designed mixing paddles are gentle on product, this method poses valuable advantages for all forms of bud. Various system sizes are available from 60 to 400 cubic foot volumes.

| Capacity | 60cf | 100cf | 200cf | 400cf |

| Material Temperature Degree F | 145-165 | 145-165 | 145-165 | 145-165 |

| Maximum Machine Temp Degree F | 350 | 350 | 350 | 350 |

| Temperature Sensor | Infrared & RTD | Infrared & RTD | Infrared & RTD | Infrared & RTD Measurement |

| Machine Materials | T304 Stainless Steel | T304 Stainless Steel | T304 Stainless Steel | T304 Stainless Steel |

| Electrical Requirements | 3PH 480V 50/60Hz | 3PH 480V 50/60Hz | 3PH 480V 50/60Hz | 3PH 480V 50/60Hz |

| Initial Wet Material Weight (75% moisture) | 600 | 1,000 | 2,000 | 3,000 |

| Rate of Water Removal (lbs/hr) | 188.0 | 187.5 | 375.0 | 749.7 |

| Final Dry Material Weight (10% moisture) | 167 | 278 | 556 | 833 |

| Total Dry Time (hrs) | 2.3 | 3.85 | 3.85 | 2.89 |

| Average Applied Power (kW) | 80 | 80 | 160 | 320 |

| Dried Material Rate (lbs/hr) | 72.5 | 72.2 | 144.3 | 288.3 |

| Power Density (W/lb) | 133.3 | 80.0 | 80.0 | 106.7 |