In-Line Magnets

Magnets are the first defense against stray metal particulates for every product line. They’re effective, low-cost, and can be fitted virtually anywhere. Most applications use ceramic, alnico, or rare-earth magnets; ceramic and alnico being less expensive and rare-earth being more effective.

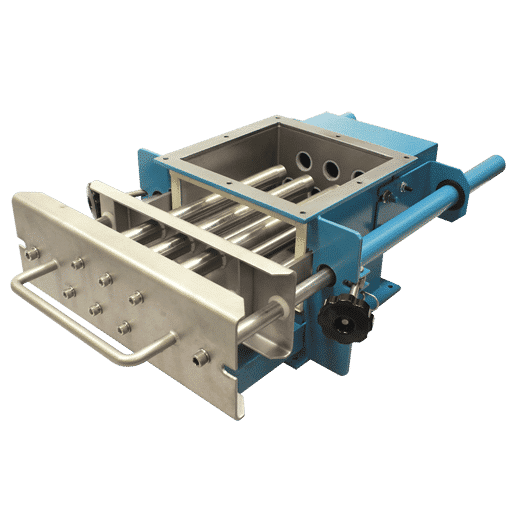

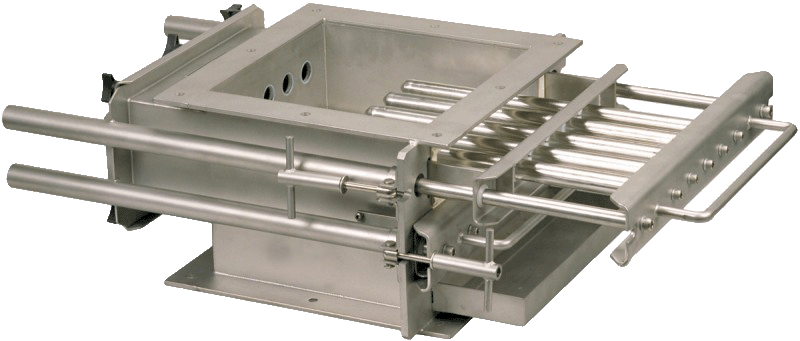

Drawer Magnets

Drawer magnets are so-called because the cylinders pull out like drawers. Pneumatic or manual describe the method by which the cylinders are discharged, and standard or self-cleaning refers to how they are cleared of contaminants. Standard cleaning means wiped by hand and self-cleaning systems allow contaminants to fall after leaving a magnetic field. These terms are used across applications of magnetic separation.

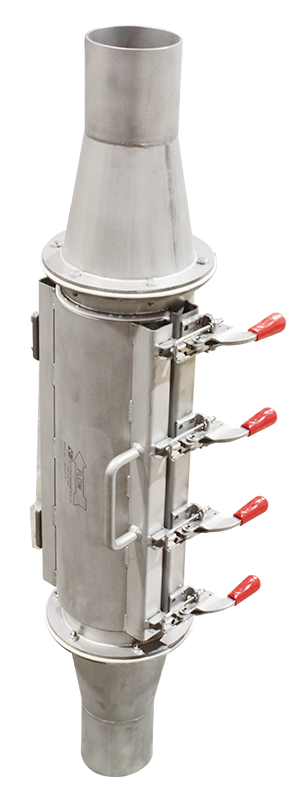

Drawer Magnets (Small)

The FF Series is designed for free-flowing product applications, excels in high temperatures, and can support 10,000 lb loads. It features single-motion cleaning magnets and comes with various options; an internal No-Spill™ slide gate and purge hopper for messless cleaning, a dump tube for load clearing, and a liquid port for easy resin coloration or temperature monitoring. There are low-profile models and others designed for fine-grained and dry resins.

Drawer Magnets (Large)

HF Drawer Magnets are larger versions of the FF Series. They flow bulk product over bar magnets and come in any style: manual standard cleaning, manual self-cleaning, pneumatic self-cleaning, and pneumatic self-cleaning.

Drum Magnets

Drum magnets allow high-volume removal and separation of ferrous and non-ferrous metals. They are self-cleaning, come in three different rare earth options, and allow high-volume throughput without the need for cleaning or interrupting product flow.

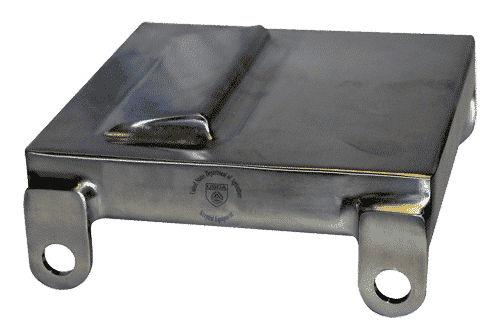

Plate Magnets

Plate magnets are general-use products that come in a variety of forms and can be placed numerous places along a line. Product flows freely over the magnetic surface, typically sloped 30-60°, with enough space that it doesn’t bridge. The tapered surface protects against contaminant wipe-off in rapid-flow applications.

Plate magnets

Where space is limited, isolated plate magnets can be integrated into existing equipment or placed above/below product as it’s conveyed.

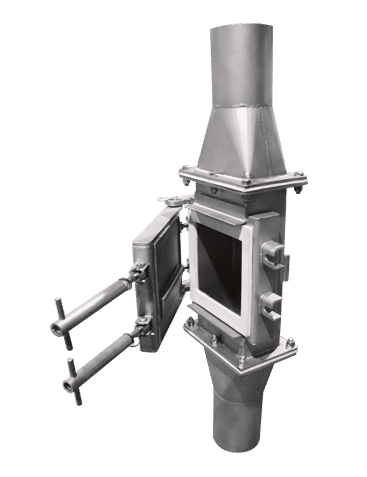

Hump magnets

Hump magnets are the standard solution for plate magnet applications. They come with optional self-cleaning features and metal-detectable gaskets and grommets.

Enclosed pipe magnets

Enclosed pipe magnets allow unobstructed dry product flow in gravity and pneumatically fed applications. Magnets for gravity-fed applications can be angled as much as 60°, and pneumatic conveying solutions are operable at up to 15 psi.

Magnetic liquid traps

Magnetic liquid traps remove ferrous tramp metal from liquid processing and conveying lines. The plate style is designed for viscous and fibrous liquids, but there is also a cartridge style designed for non-fibrous applications.

Specialty Magnets

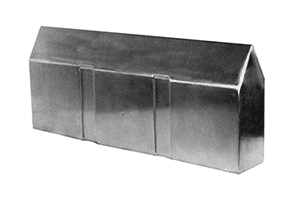

Wedge magnets

Wedge magnets are primarily for protecting pellet mills and particulate-processing equipment from damage from tramp metal. They’re placed in narrow, vertical, or steeply inclined chutes because they need to be cleaned manually and should be easily accessible.

Torpedo magnets

Torpedo magnets were designed to protect plastic molding machines and are suspended in the center of a JIT loader’s glass tube.

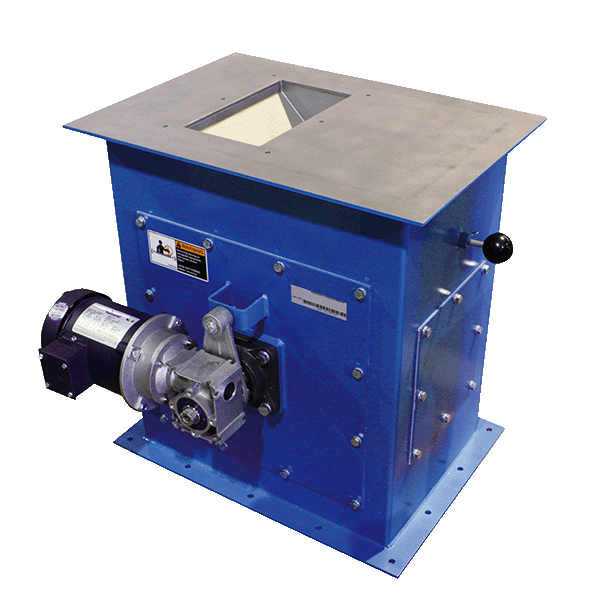

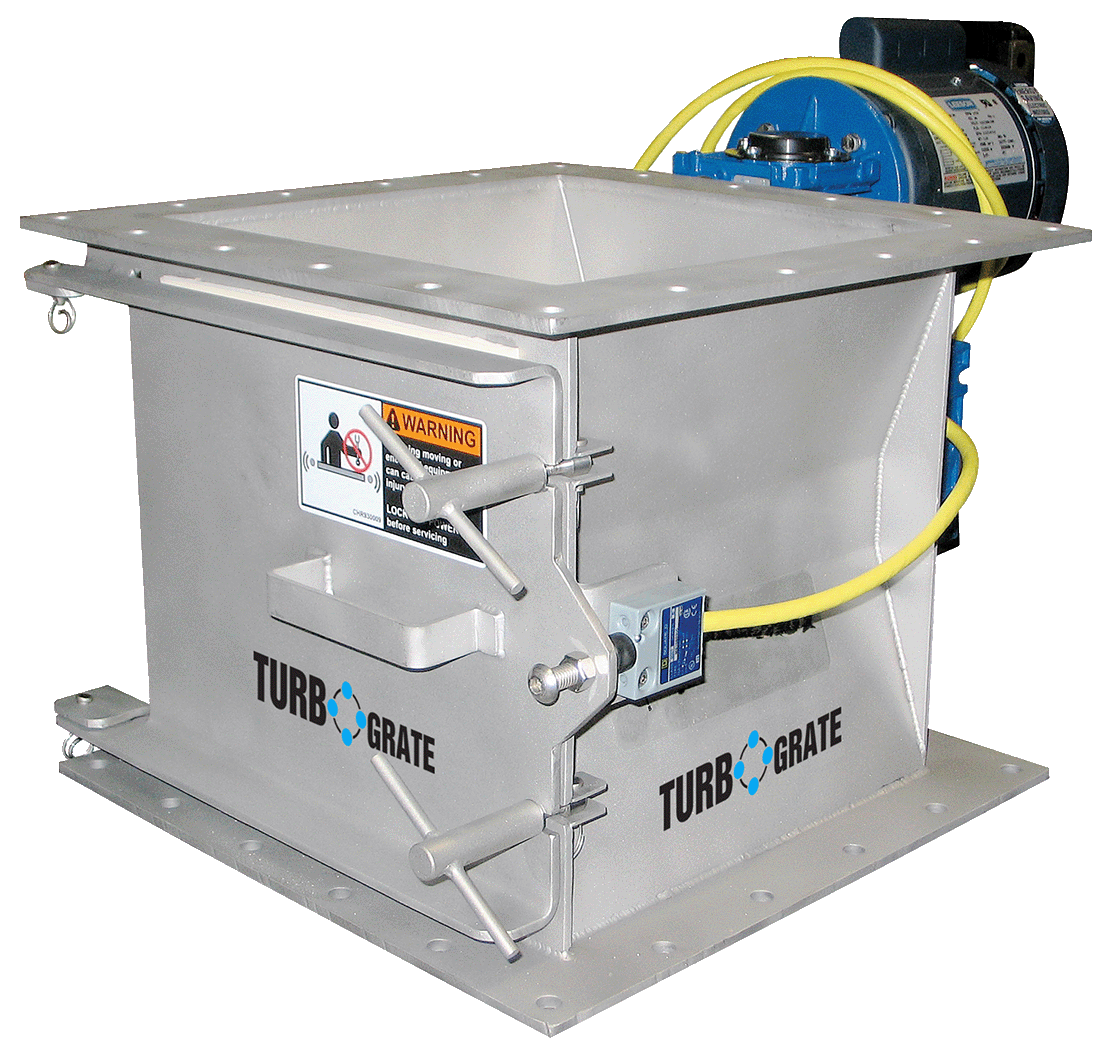

Turbogrates

The TurboGrate employs a rotating grate magnet and flow-assist features to separate metal from especially flow-resistant product. It can be customized to fit your application and is available in a self-cleaning option.