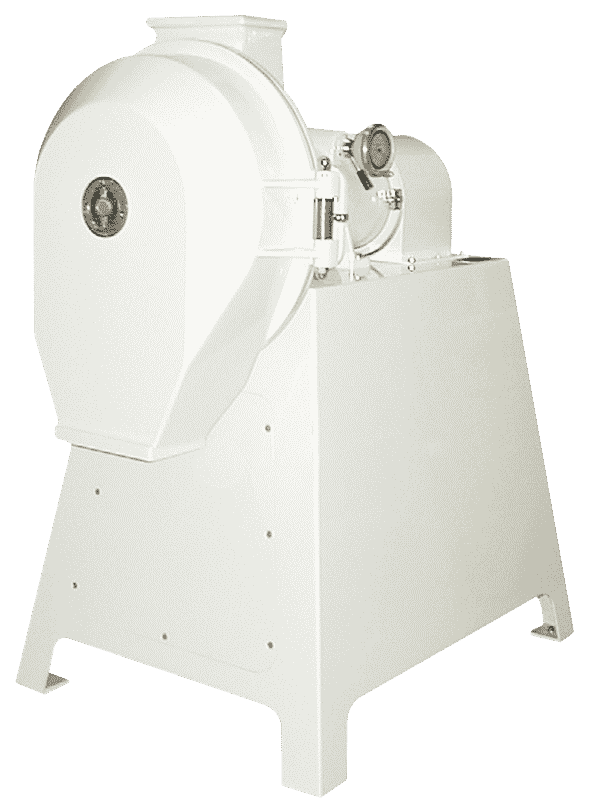

Cereal Grain Mill

Operating Principle

A consistent flow of product enters the inlet (as seen in the diagram at A) located at the top of the Cereal Grain Mill, and travels through the center of the stationary disc (B) into the milling chamber (C). The rotating disc (D), mounted on the center shaft (E), accelerates and distributes grains over the grinding surface of the two discs. The distance between the discs can be precisely adjusted for on-the-fly fine-tuning. No screen is necessary, and in many cases further sifting is also unnecessary. Disc speed is easily changed for different grains, as are the corrugation patterns via easily-changeable discs. The discs are made from a special wolfram carbide alloy, delivering the market-leading durability. The ground product is then discharged via the outlet (F). Note: we recommend using suction from either pneumatic conveying or an exhaust system to maintain slight negative pressure in the milling chamber to assist flow.

Advantages

- Compact, contained design minimizes footprint and installation cost.

- Easily-accessible, durable wearing parts reduce maintenance costs.

- Easy-change elements minimize down-time and operating costs.

- Exchangeable discs with multiple corrugation patterns suit many applications.

- Simple & accurate handwheel adjustment of the grinding gap helps achieve consistent and uniform products.

- Large, screenless grinding surfaces deliver high capacity and reduce power consumption.