Food Processing Equipment Engineering

ABM Equipment provides complete engineering services for food processing equipment including mechanical engineering of custom equipment and process engineering for the flow of the system. ABM engineers use their extensive knowlege of products like yours to deliver quality equipment and systems you can count on. Each flow comes with equipment layouts that Operations Managers can click on and be taken to the appropriate manuals and parts lists, of course including custom equipment. All equipment sold is supported, 24/7/365.

Services

Equipment Design and Customization

Each food processing facility has its own unique layouts, methods, and requirements. Our team of skilled engineers design and customize processing and handling sytems to suit your SOPs and requirements. From concept development to design, we ensure that every piece of equipment aligns with your processes, specifications, and safety standards. We can help you creatively navigate State restrictions and satisfy buyer audits much more easily.

Equipment Installation and Integration

Our services go beyond just equipment design. We take care of the entire installation process, ensuring seamless integration with your existing production line. Our technicians work efficiently to minimize downtime and disruption to daily operations so you can maintain the highest level of production possible.

Equipment Upgrades and Retrofits

We provide comprehensive equipment upgrade and retrofit solutions, for most dry bulk solids handling, processing, packaging, and inspection equipment, including X-ray. This can be done on one-off bases or for a system as a whole.

Our process engineers are intimately familiar with available technologies and can audit your existing equipment or system to identify areas for improvement. We then develop customized upgrade and retrofit plans that address these areas, incorporating the latest technologies and industry advancements.

Equipment upgrades can include enhancements such as improved automation, increased capacity, energy efficiency improvements, or advanced control systems. Retrofits involve replacing outdated components with newer, more efficient ones. We can also design custom transitions to fit newer equipment with older.

Common Reasons Custom Equipment is Needed

Equipment engineering and customization is necessary in virtually every full-scale food processing line on the planet. No two systems are exactly the same, and each has specific operational challenges and requirements. Here are some common examples of situations where custom equipment is needed:

Unique Manufacturing Method

Industries with specialized manufacturing processes may require custom equipment to accommodate unique product specifications or production requirements. Custom equipment ensures optimal performance and efficiency in these specialized operations.

Non-Standard Product Sizes or Shapes

When manufacturing products with non-standard sizes or shapes, custom equipment is necessary to handle these variations. Customization allows for precise handling and processing, ensuring consistent quality and minimizing waste.

Limited Space or Building Constraints

In facilities with limited space, off-the-shelf equipment may not fit or operate efficiently. Custom equipment can be designed to maximize space utilization and fit seamlessly within existing layouts, optimizing production capacity.

Impractical Regulations

Certain industries, such as pharmaceutical or food processing, have strict regulatory requirements. And in smaller municipalities where the applicable restrains were never made with your product in mind, compliance can be clunky. Custom equipment ensures compliance with these regulations, incorporating necessary features and controls to meet industry standards. In these situations, our creative engineers are a large value-add.

Unique Product Handling Requirements

Products with specific handling requirements, such as delicate materials or hazardous substances, may require custom equipment to bring equipment with the other features you need into alignment.

Why ABM?

Expertise

Our team of engineers and technicians are highly skilled and experienced in the food processing industry. We understand the complexities and challenges you face and provide solutions that work seamlessly for your unique operations.

Custom Approach

We believe that one size does not fit all. Our approach is to understand your specific requirements and deliver tailor-made solutions that align perfectly with your business goals.

Thorough Approach

We can help you manage:

- Product variability

- Scale-up & scale down (pilot systems)

- Processing time & throughput

- Automation & integration

- Energy efficiency

Innovation

We stay at the forefront of technological advancements and continuously innovate to offer the most efficient and sustainable equipment solutions.

Customer-Centric

Customer satisfaction is our top priority. We work closely with you throughout the project to ensure your needs are met and expectations exceeded.

Equipment Specialties

- Silos

- Bulk bag unloaders

- Bulk bag fillers

- Packaging machinery and systems (automatic and semi-manual)

- Conveyor systems

- Mixing and blending equipment

- Dairy processing equipment

- Food drying and dehydration systems

- Food sorting and grading machines

- Meat processing equipment

- Snack food production machinery

- Filling and sealing machines

- Bulk handling equipment

- Dust collection systems

- Processing equipment and machinery

- Food inspection and detection systems

- Food packaging inspection systems

- Waste recycling systems

- Food grinding and milling machines

- Food mixing and proportioning systems

- Food portioning and weighing machines

- Food drying equipment

- Continuous food processing systems

- Mixers and blenders

- Conveyors

- Grinders

- Homogenizers

- Filling machines

- Wrapping machines

- Drying machines

- Cutting and mortioning machines

- Coating machines

- Packaging machines

- Dispensing machines

- Milling machines

- Extraction equipment

- Evaporation systems

- Mixing tanks

- Pneumatic conveying systems /air handling systems

- Dust collection systems

- Particle size reduction equipment

- Vacuum Packing Machines

- Bag dump stations

- Screening equipment

Product Specialties

- Cakes

- Patries

- Confectionary

- Gummies

- Hard Candies & Suckers

- Bars

- Chocolates (High-Capacity)

- Sausages

- Processed Meats

- Snack Foods

- Chips

- Pretzels

- Popcord

- Coffee

- Frozen Foods

- Cereal

- Prepared and Ready-to-Eat Meals

- Processed Seafood

- Canned Fruits and Vegetables

- Nut and Seed Products

- Baby Foods

- Bakery Mixes and Ingredients

- Grain and Flour Products

- Dried Fruits and Vegetables

- Grains

- Soups and Broths

- Almonds

- Fruit and Vegetable Juices

- Food Powders and Seasonings

- Plant-Based Alternatives (Plant-Based Meat, Milk Alternatives)

- Instant Foods (Instant Coffee, Instant Noodles)

- Egg Products

- Energy Bars, Candy Bars, & Protein Bars

- Meal Replacement Products

- Rice and Rice Products

Industry Specialties

- Bakery & Confectionary

- Dairy

- Baby Food

- Meat

- Beef

- Pork

- Poultry

- Seafood

- Fruits and Vegetables

- Snack Foods

- Nuts

- Nutraceuticals

- Pet Food

- Frozen Foods

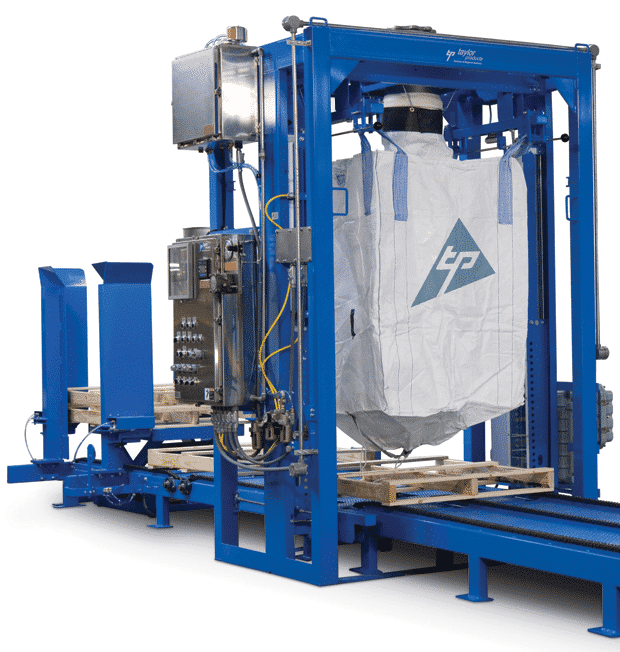

Bulk Bag Fillers

Bulk Bag Fillers, also known as super sack loaders, package product...

Paddle Mixers

Whereas ribbon blenders create opposing streams in a vessel, paddle...

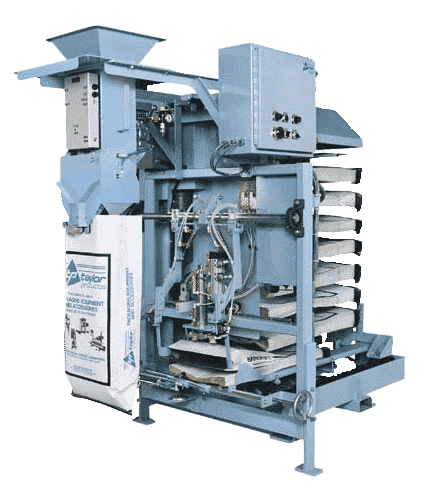

Bag Placers

Bag placers are standalone placing machines meant to be integrated...

Checkweighers

Checkweighers Checkweighers ensure product is not over or...