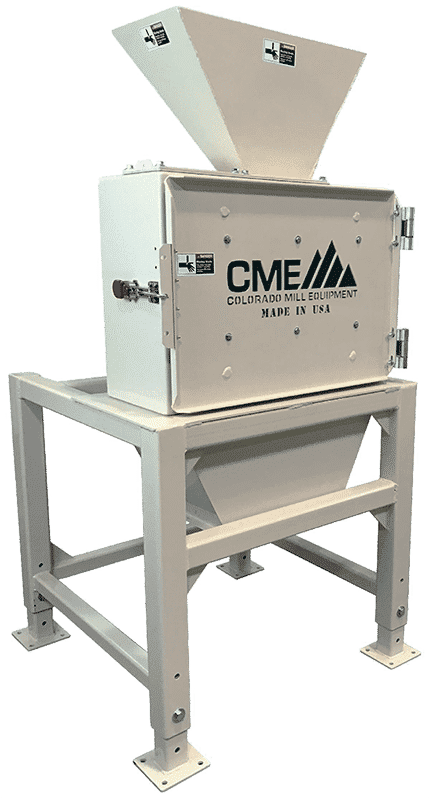

Herb Mills

If bud isn’t shredded finely enough for drying, mills are needed to reduce the particle size for primary extraction in order to achieve the best yields. (For particle size reduction before drying, see shredders instead). Because of bud’s tendency to clog screens when wet or particularly oil-laden, mills often need to be paired with forced air to clear the screens—and remove dust. This can be accomplished with a dedicated blower—added as an option—or by connecting an external pneumatic system, in which case the extra air can also be used to convey the herb from milling to extraction or storage. Either way the blower should have a way to collect trichomes, as a statistically significant portion is lost at this step. Hammer mills are far-and-away the most effective type of mills for pre-dried herb, and are available in a number of different configurations, detailed below.

Options

Light, standard, or heavy-duty

In-feed magnet

Telescoping legs

Single-phase motor

Isolation pads

Carbide motor

Carbon or stainless blower

Custom in-feeds and outlets

| Throughputs | Models for 100 – 10,000 lbs/hr available |

| Motor Sizes | 3 – 400 HP |

| Screen Sizes | 476 – 5,280″ |

| Screen Area | 700 lbs. per skid |

| No. of Hammers | 15 – 112 |

| Dimensions | 38L x 31W x 35H – 115L x 68W x 81H” |

| Weight | 500 – 10,000 lbs. |

| Made In | USA |