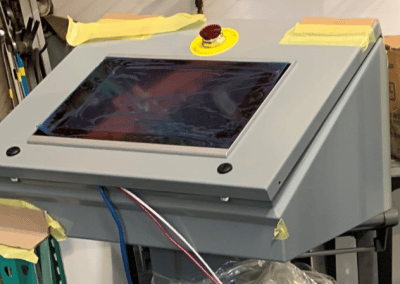

Process Controls

Process control is a critical aspect of modern manufacturing and production operations. It involves the use of technology and software to manage and monitor production processes, ensuring that they run smoothly, efficiently, and according to specifications. Process control offers numerous benefits to companies, including recipe programming, remote access, analytics, and IOT integration.

Recipe Programming

Recipe programming allows manufacturers to automate their production processes by creating step-by-step instructions for the production process. This helps to standardize production, minimize variability, and reduce the risk of human error. Recipe programming can also be customized to meet specific production requirements, making it easier to adapt to changing market conditions.

Remote Access

Remote access to process control systems is a valuable tool for manufacturers, allowing them to monitor and control production processes from anywhere in the world. This helps to increase productivity, reduce downtime, and improve overall production efficiency. Remote access also enables manufacturers to respond quickly to issues and make real-time decisions, helping to improve overall production quality.

Analytics

Process control systems equipped with advanced analytics capabilities allow manufacturers to track and analyze production data in real-time. This data can be used to identify trends, optimize production processes, and make data-driven decisions. Analytics also helps to identify areas for improvement and make predictions about future production performance, allowing manufacturers to proactively address potential issues before they become problems.

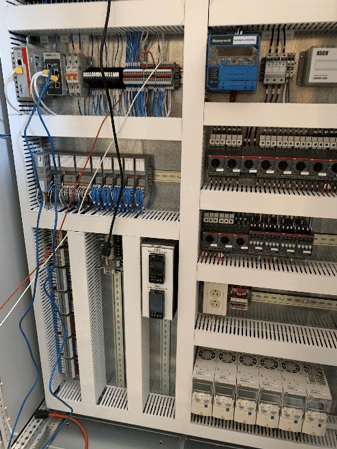

IOT Integration

The Internet of Things (IoT) has revolutionized the way that manufacturers approach production, enabling them to connect their process control systems to a wide range of devices and sensors. This integration allows for real-time monitoring of production processes and the collection of data from multiple sources, helping to improve production efficiency and quality. IoT integration also enables manufacturers to respond quickly to changes in the production environment, allowing them to make real-time decisions that improve production performance.

Go to DSOSentinel.com to learn about our new analytics software that can compile data from any equipment with outputs and generate complete system reports.

Benefits of the right process controls

- Increased Efficiency: Process control helps automate and streamline production processes, reducing the risk of human error and increasing efficiency. This can lead to faster production times, lower costs, and improved production accuracy.

- Improved Product Quality: Process control allows food processing companies to monitor production processes in real-time, ensuring that products are produced to industry standards and customer specifications. This helps to minimize variability and improve the overall quality of the final product.

- Enhanced Food Safety: Process control helps to monitor production processes and identify potential food safety issues, allowing companies to quickly address any concerns and maintain the safety of their products.

- Real-time Monitoring: Process control enables food processing companies to monitor production processes in real-time, providing up-to-date information on the status of production. This helps to quickly identify any issues and make informed decisions that improve production efficiency and quality.

- Traceability: Process control helps to track the production of food products from start to finish, providing a complete and detailed record of production history. This helps to ensure product traceability, enabling food processing companies to quickly recall products in case of a food safety issue.