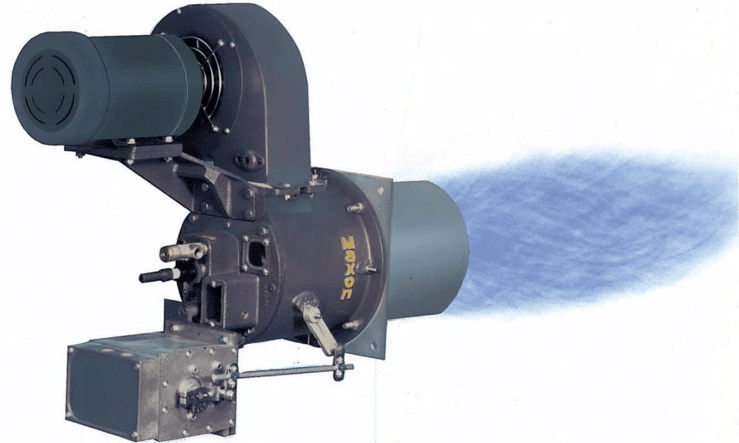

Details

- 40:1 turndown ratio.

- Flame Length: 3.5-5′.

- Fuel: Propane Gas.

- Backplate: ANSI Threaded.

- Spark Ignitor: Standard Ignitor.

- Adjustable Orifice: Standard Adjustable Orifice.

- Observation Glass: Standard Observation Glass.

- Flame Detection: No Flame Detection.

- Mixing Cone: Excess Air Mixing Cone.

- Discharge Sleeve: 4-8” 310SS.

- Oven Wall Gasket: No Wall Gasket.

- Connecting Base & Linkage: Honeywell Modutrol Electric CB&L.

- Control Motor: No Control Motor.

- Switch: No Switch.

- Filter, Silencer, Guard Position: No filter, or Silencer.

- Universal Joint Assembly: No Universal Joint.

- Manual Handle: No Manual Handle.

- Max Airstream Temp: 1000°F.

- Guide Tube: Carbon Steel.

- Carbon Steel Combustion Chamber.

Fuel Train Assembly for 3.5MBTU Burner:

- Honeywell double block and bleed fuel train with a capacity of 3.5 MBTU.

- Fuel is propane gas.

- Inlet fuel pressure not to exceed 10PSIG.

- Minimum fuel inlet pressure 5PSIG.

- Outdoor use.

- Pre-piped gas trains are designed to adhere to the NFPA 86.

- The fuel trains are to be mounted to a fabricated rack approximately 4.5’ long x 2’ wide x 3’ high.

Fuel Rack Construction

- Framing 3” square tubing.

- The four corners will have support legs with a 8’’sq x 3/4” thick floor plate drilled and tapped for leveling and mounting purposes.

- 2” x 2’’ x ¼” metal angle can be used for support between the framing.

- Welded construction and all surfaces to be ground smooth.

- Prior to painting all surfaces to be coated shall be clean, dry, and free from contamination.

- Painting color shall be industrial gray, follow manufacturer’s recommendations for surface preparation, application, and safety.

- BMS / Combustion control panel will be mounted to rack. The panel will need to be clear from obstructing view of fuel train hardware.

Fuel Train Assembly and Painting:

- All piping mounted to rack will be fastened with Hydec or equivalent weld on pipe mounts

- Welded construction and all surfaces to be ground smooth.

- Prior to painting all surfaces to be coated shall be clean, dry, and free from contamination.

- Painting color shall be industrial safety yellow, follow manufacturer’s recommendations for surface preparation, application, and safety.

Maxon Custom 1.5” NPT Fuel Pipe Train Assembly:

- Pipe train configuration: 1.5” NPT, double block arrangement.

- Fuel: Propane gas.

- Component enclosure rating: NEMA 4 – Indoor/outdoor with wash down.

- Pipe train voltage: 115V/1ph/60Hz.

- Ambient temperature rating: 20°F to 110°F.

- Fuel supply pressure: 10 psi.

- Main fuel flow: 3.5 MBTU.

- Pilot train: 1/2” NPT, double block arrangement.

- Pilot fuel flow: 800 scfh.

- Rack mounting: Included.

- Pre-wiring: Included

1.5” NPT Main Gas Train Items:

- Manual isolation inlet ball valve: Jomar 316 SS ball & stem, with lockable.

- Sediment trap: Included.

- Y-strainer: Mueller 351M, bronze, 2” NPT, with 40 mesh stainless steel screen.

- Inlet pressure gauge: 0-30 psig, with isolation valve.

- Gas pressure regulator: Sensus 243-12-2 with 1-2”psig Spring.

- Low gas pressure switch: UE, 2.5”-50”wc , auto reset, NEMA 4X.

- Low pressure switch gauge: 0-30” wc, with isolation valve.

- Shut-off & blocking valves: Honeywell V5055/V4055 1.5” NPT, Buna-N seals, cast iron body, trim package 1, 115V/60Hz, 13-second timing, VOS-2/VCS-2, NEMA 4, with leak test arrangement.

- Vent valve: ASCO N.O. solenoid, 1” NPT, 115V/60Hz, High gas pressure switch: UE, 10”-250”wc, manual reset, NEMA 4X.

- High pressure switch gauge: 0-30 psig, with isolation valve.

- Manual isolation outlet ball valve: Apollo 77-140, brass, 2.5” NPT, 316 SS ball and stem with lockable handle.

1/2” NPT Pilot Gas Train Items:

- Manual isolation ball valve: Apollo 77-140, brass, 2.5” NPT, 316 SS ball and stem with lockable handle.

- Gas pressure regulator: Sensus 496, 1/2” NPT, ¼” orifice, 6”-14” wc. Spring.

- Shut-off & blocking valves: ASCO N.C. solenoid, ½” NPT, 115V/60Hz, NEMA 4X, with leak test arrangement.

- Pressure gauge: 0-15” wc., with Apollo 77-140 isolation valve.

- Manual isolation ball valve: Apollo 77-140, brass, ½” NPT, 316 SS ball & stem, with lockable handle.

Honeywell 7800 Burner Control Panels (Mounted to Fuel Train Assembly):

- Requires 230VAC/60Hz/3 Phase Power.

- One Honeywell 7800 Series based flame safeguard with flame safety, UV flame amplifier, and flame safety wiring base (with necessary relays, terminal blocks, fusing, breakers, and wireway.

- Honeywell 7800 Series Display included a NEMA 4 cover assembly.

- Honeywell UDC high temperature limit.

- Below lamps, pushbuttons, and selector switches to be AB 800T series.

- Mounted on Panel Door:

- Control Power On White Pilot Light

- Combustion blower hand / off / auto Indicating green selector switch

- Burner Start 2 position selector switch

- Limits Complete Indicating green lamp

- Pilot Gas ON indicating yellow lamp

- Main Gas On indicating blue lamp

- Emergency Stop indicating red Pushbutton

- Alarm Horn and alarm silence pushbutton

- BMS and Combustion Loose and Unmounted Equipment:

- Honeywell UV flame scanner

- Combustion air pressure switch

- Burner Ignition Transformer J-Box

- Ignition wire 10’ and electrical ends

- Burner and Process Temperature 18” dual Type J thermocouples

- Thermocouple wire 200’