Scaling Dry Bulk Solids Packaging Lines

Choosing Equipment

Equipment selection is a process you will likely want to outsource, as you will have to consider technical capabilities, labor requirements, worker safety, maintainability/serviceability, reliability, ability to work with which other equipment, capital cost, floor space, flexibility (replacement, materials, etc.), energy consumption, quality contribution or cost, qualifications/certifications based on your product and governing body, throughput, efficiency, productivity, and ergonomics/ease-of-use. But here are some steps to get you started.

Production Volume: Determine your daily throughput goals.

Product Characteristics: Whether you’re packaging liquids, powders, or solid items, ensure compatibility with equipment like form fill sealers, open-mouth baggers, or vacuum packagers.

Future Scalability: Choose modular systems like palletizers or bulk bag fillers that allow for future expansion.

Equipment Type: For instance, upgrading from a semi-automatic bagger to a fully-automatic bagger with integrated bag placers and sewers will become cheaper once you reach a certain volume.

Vacuum Packagers

Manual tabletop vacuum packagers are where most people will start. As demand grows, consider upgrading to automatic single or double-chamber vacuum packagers or fully automatic systems for high-volume operations. These machines cater to a range of product sizes and production needs.

Form Fill Sealers (FFS) and Thermoformers

Form fill sealers offer efficient packaging by forming bags from rolls of film, filling them, and sealing them in a single process. Thermoformers take this further by forming rigid or semi-rigid packaging trays, making them ideal for products requiring structured containment. Rotary thermoformers provide enhanced efficiency for large-scale operations.

Bagging Systems

Bagging systems cater to diverse product types and bag styles:

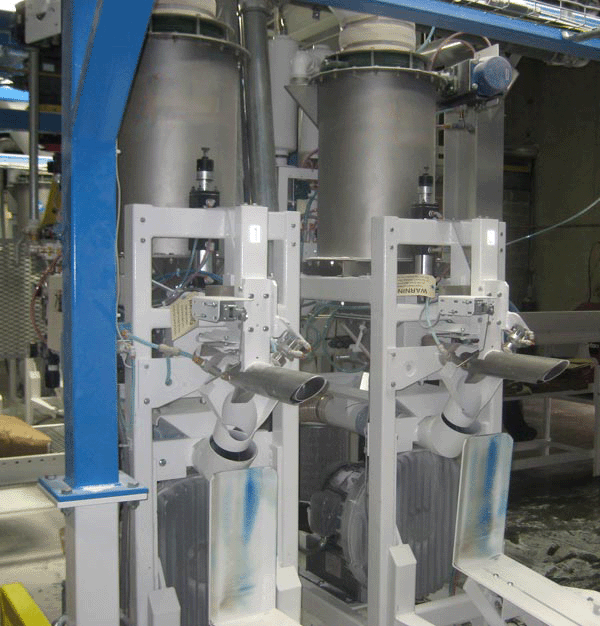

Valve Bag Fillers: Designed for powders and granular materials, these ensure efficient, dust-free filling.

Open-Mouth Baggers: Ideal for bulk products, these systems offer flexibility for different bag types.

Semi and Fully Automatic Baggers: As your operation grows, moving to fully automated baggers with integrated bag placers and sewers reduces labor and increases throughput.

Bulk Bag Fillers

For handling large volumes of bulk materials, bulk bag fillers provide an efficient solution. These systems are ideal for industries dealing with raw materials or high-capacity production, offering options for compact, adjustable, and standard designs.

Palletizers

Automating palletizing operations is a key step in scaling up packaging. Both robotic and conventional palletizers improve end-of-line efficiency by stacking bags or boxes precisely, reducing manual handling and associated costs.

Designing the System

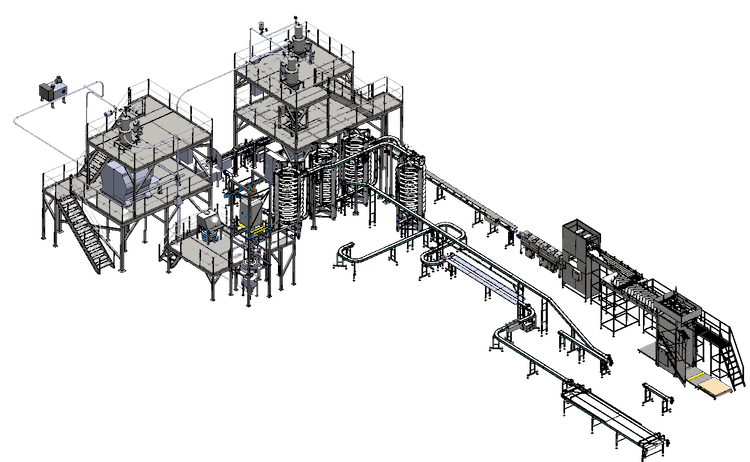

Effective system design integrates equipment into a cohesive workflow:

Layout Planning aka Process Engineering: Optimize the arrangement of equipment for material flow. Position bulk fillers, baggers, and palletizers to minimize transport time.

Automation Integration: Implement robotic systems for tasks like palletizing, ensuring a controls layout that is efficient and intuitive for workers.

Custom Features aka Mechanical Engineering: Engineers customize solutions for specific production needs; product has to make it from one piece of equipment to the other, often in the correct orientation or without being treated too roughly.

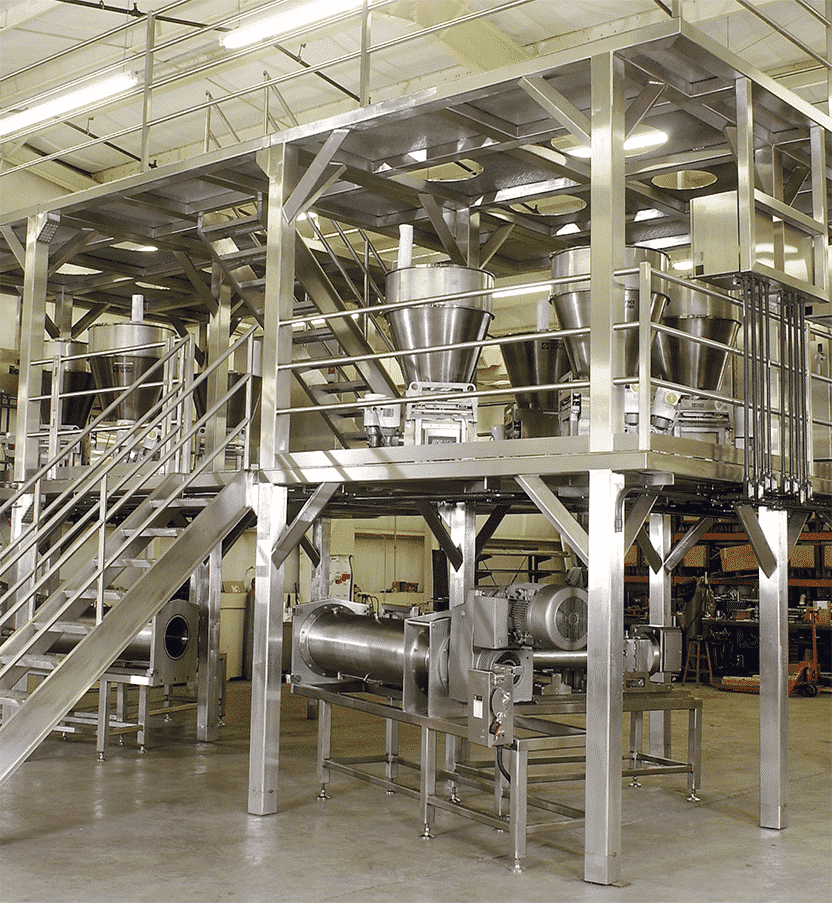

Fabrication

The custom structures to hold your equipment in the optimal position must be built, including walkways, railings, maintenance access areas, and transitions and hoppers.

Installation

A successful transition requires careful installation:

Pre-Installation Preparation: Ensure the production area is ready with adequate power, compressed air, and space.

Phased Rollout: Introduce automation in stages to test each component before full-scale implementation.

Training: Equip staff with the knowledge to operate, troubleshoot, and maintain new equipment.

Maintenance

Maintaining fully-automatic systems is critical for consistent performance:

Regular Servicing: Schedule routine maintenance for machines like valve bag fillers and thermoformers to prevent downtime.

Predictive Monitoring: Use sensors and software to identify potential issues before they escalate.

Spare Parts Management: Stock essential parts for quick replacements.