Screw Feeders

| Throughputs | 0.007–1,137 ft³/h |

| Perfect for | Powders, granules, chips, flakes & fibers, organics and inorganics, other virgin & recycled materials |

| Made In | USA |

Models

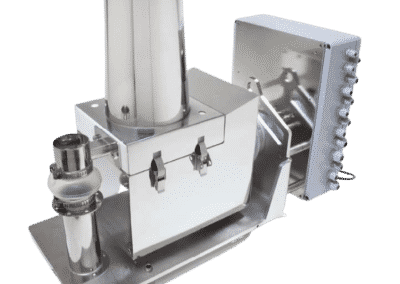

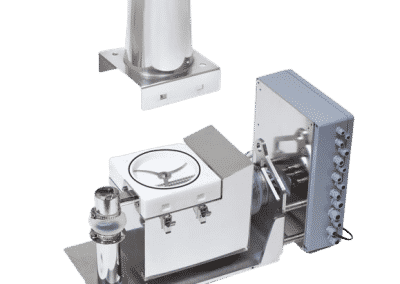

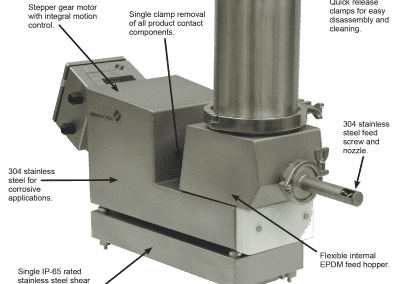

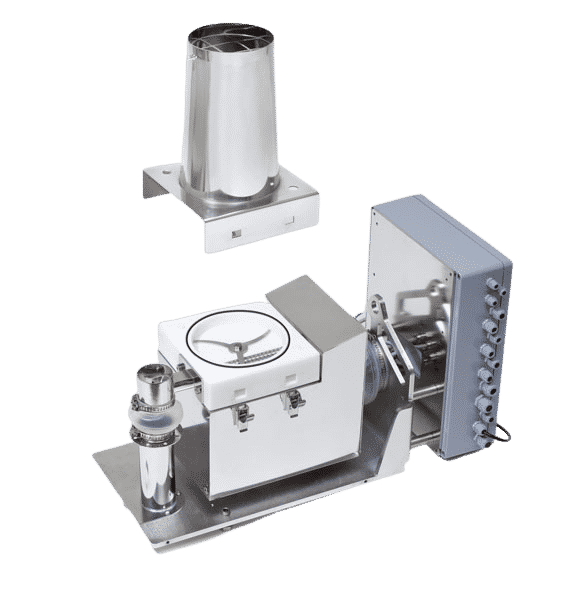

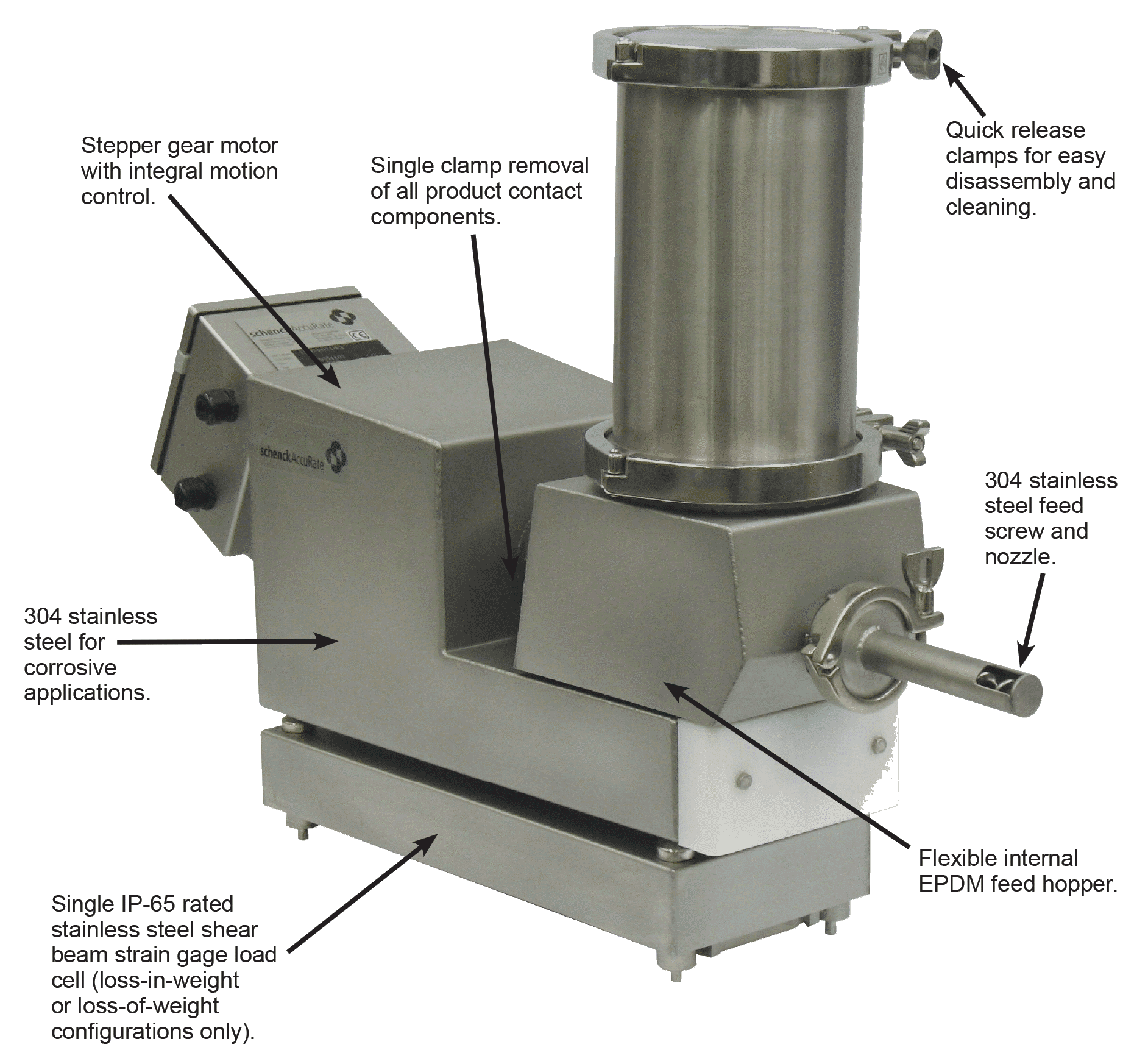

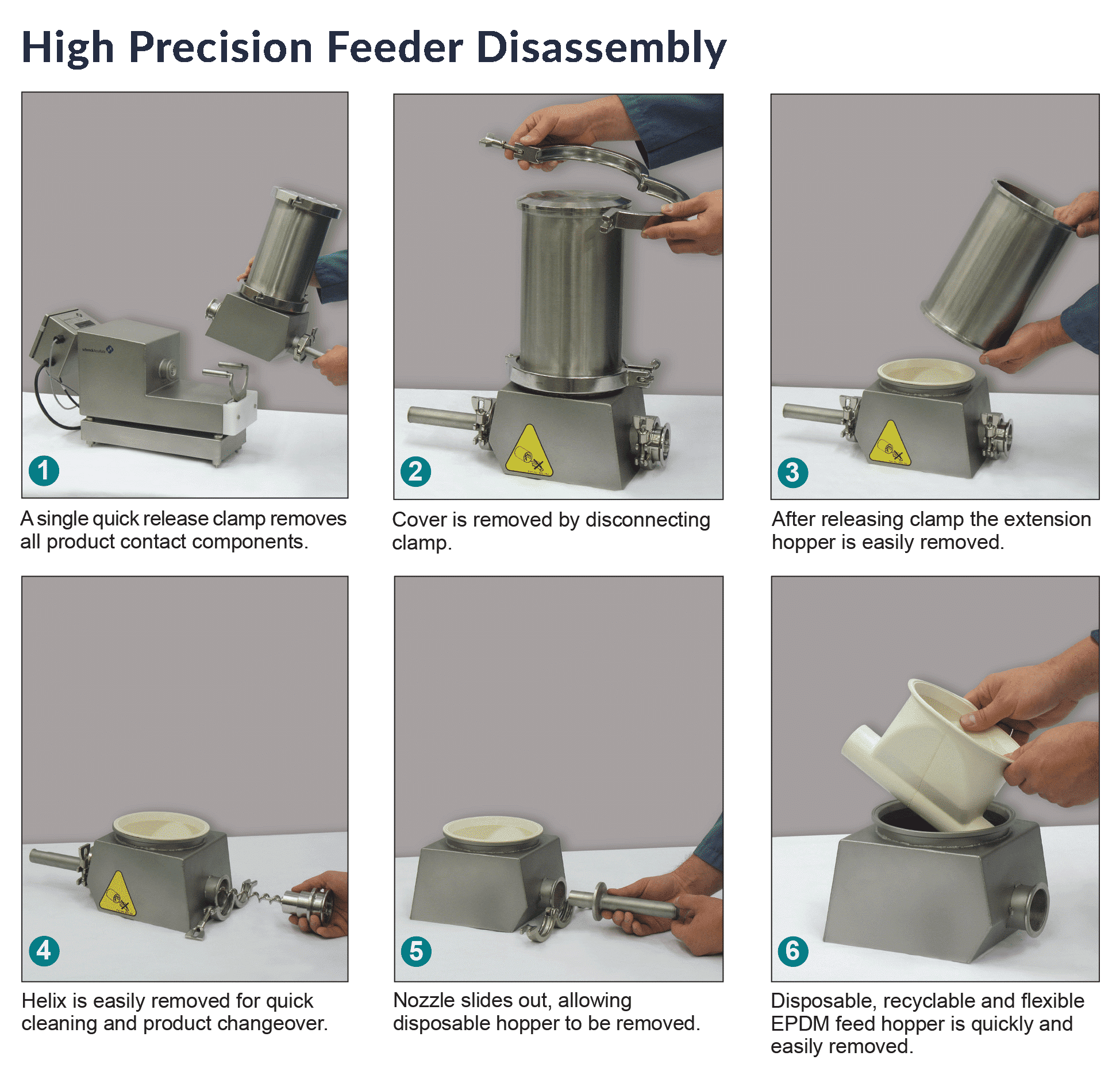

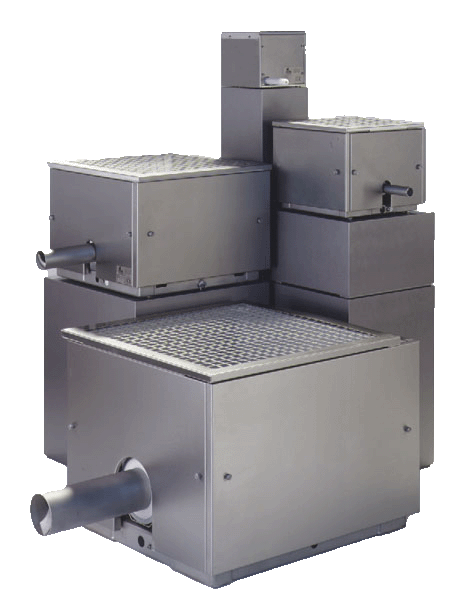

High Precision Feeders – 1.1 to 330 lbs./hr. (0.007–0.56ft³/hr, application-dependent)

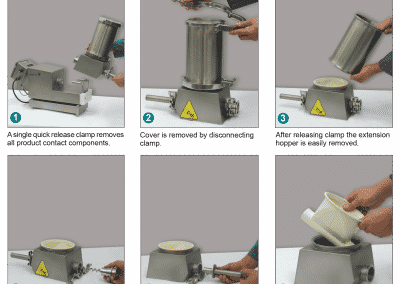

Ideal for volumetric or gravimetric low feed rate applications. This unit features a quick and easy disassembly dual arm external hopper agitation system for maximizing material handling versatility and simplified maintenance. Disposable or recyclable EPDM feed hoppers are also available.

Specs

- Accuracy:

– Gravimetric: ±0.25–1%

– Volumetric: ±1.5–2.5%

- Materials

– Contact: 304 SS (screws), EDPM, PTFE (Rulon 641)

– Non-contact: 316 SS, EDPM, PTFE, PET-P - IP65 washdown

- Dust-proof, quick-release clamps on all product-contact parts

Options

- 3-A Sanitary or Standard Configurations

- Electrical: 240V, 1-phase, 4A /or/ 120v, 1-phase, 8A

- Hopper:

– Sizes: 0 (no hopper for continuous operation), 4, 12, or 36 L

– Cover: manual or auto - Screw Diameters: 0.27, 0.5, 0.75, 1.25”

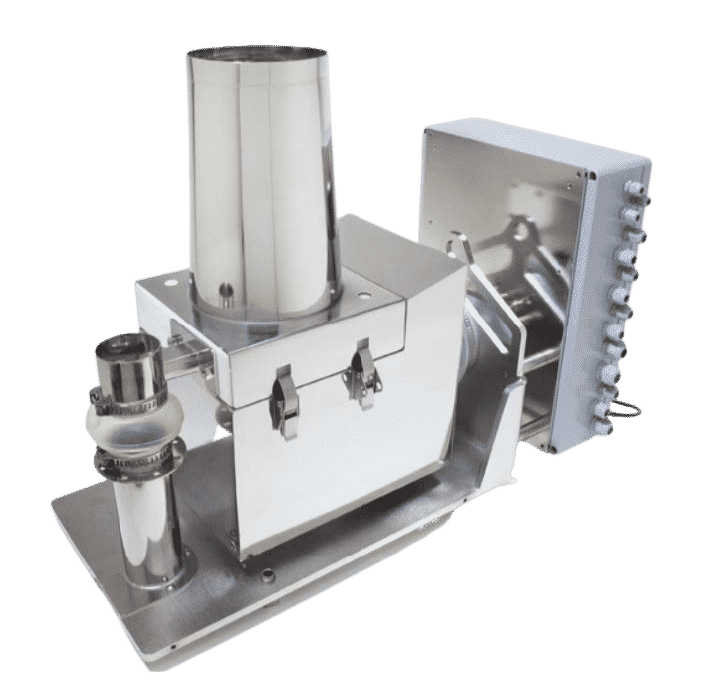

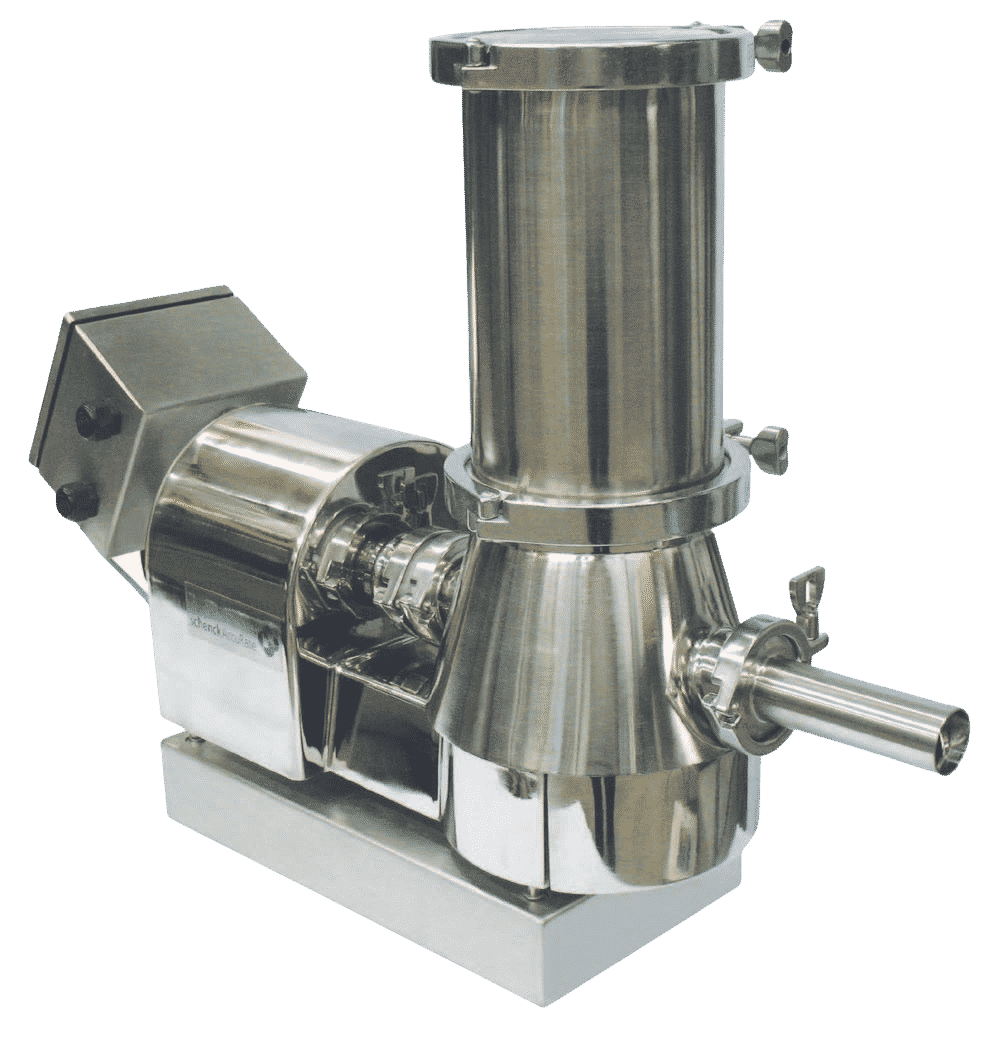

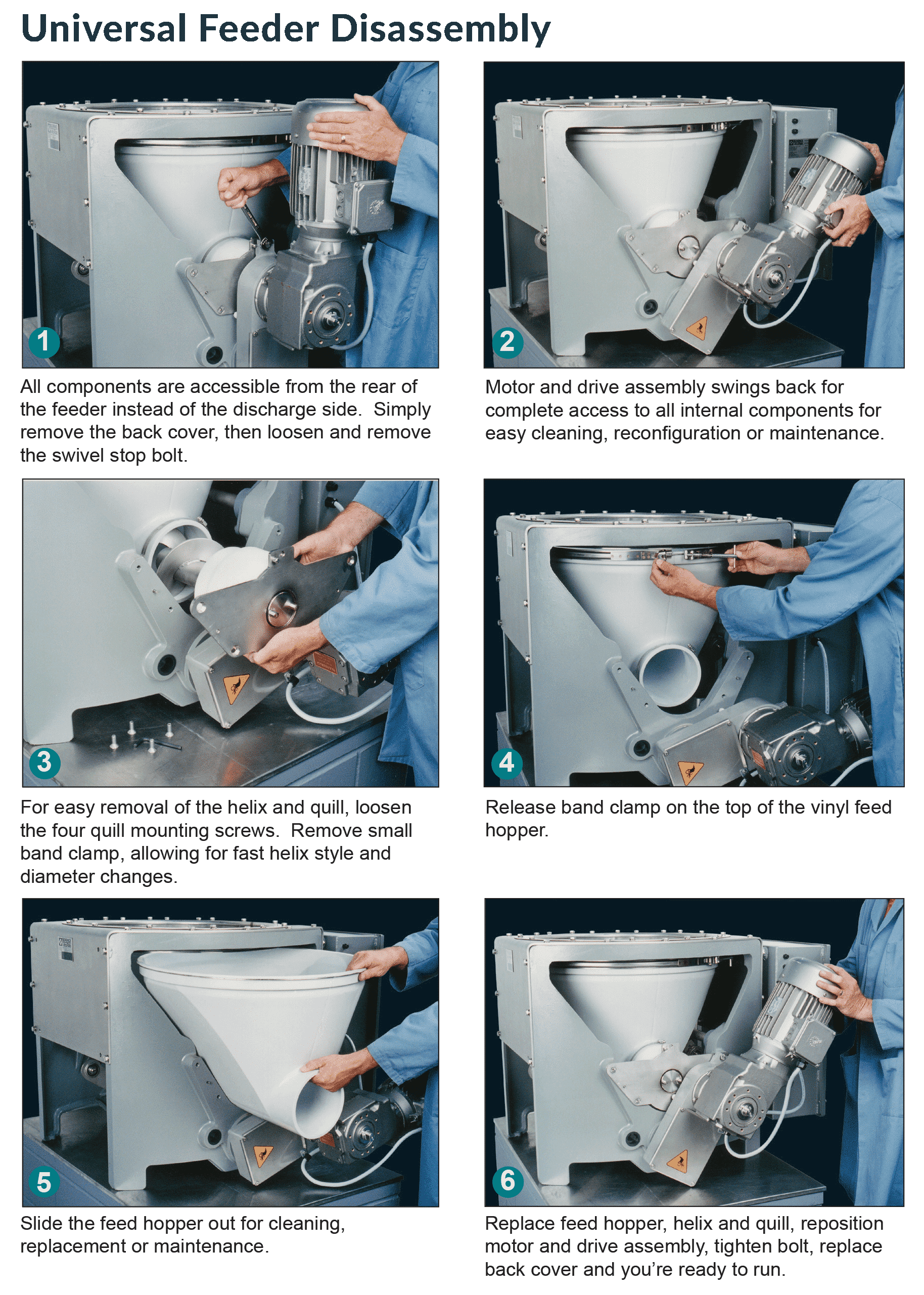

Universal Feeders – 3.4 to 1,137 ft³/hr

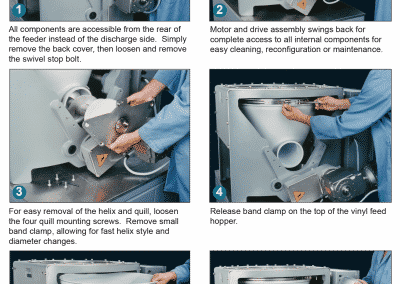

Accommodating the widest range of sizes and configurations, the Universal model (Mechatron) can operate Typical applications are found in the plastics, chemical, food, detergent pharmaceutical, building materials, and cement industries. And with components easily-accessed from the non-process side, it significantly reduces time needed for maintenance and cleaning.

Specs

- Accuracy:

– Volumetric: ±2 – 5%

– Gravimetric: to spec.

Options

- Controls: Local or remote

- Materials:

– Toner-resistant or static dissipative coating

– 304/316 SS & HDPE contact surfaces

– Standard or 3-A Sanitary configuration - Hopper

– Rigid or flexible interiors (for flow assist)

– Sizes: 0 (no hopper for continuous operation), numerous sizes from 2.9–100ft³

– Open, manual, or auto-covers - Screws

– 304 or 316 SS

– Single or dual feed - Motor

– 460 VAC, 3 PH, 50 or 60Hz

– Gear ratios: 14:45, 18:40, 24:36, or 26:32

– Explosion proof or wash down

Whereas vibratory feeders are better for irregular product and those that would damage or be damaged by feed screws, screw feeders can handle certain products better, such as liquids and viscous or sticky slurries. If your product fits in neither or both categories, reach out and we’ll identify the best solution.

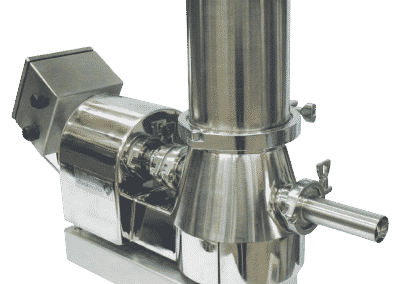

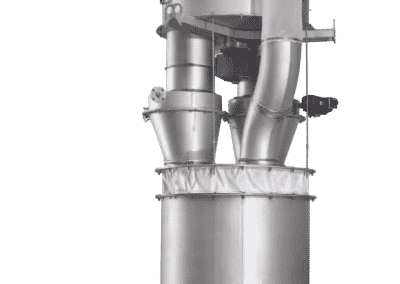

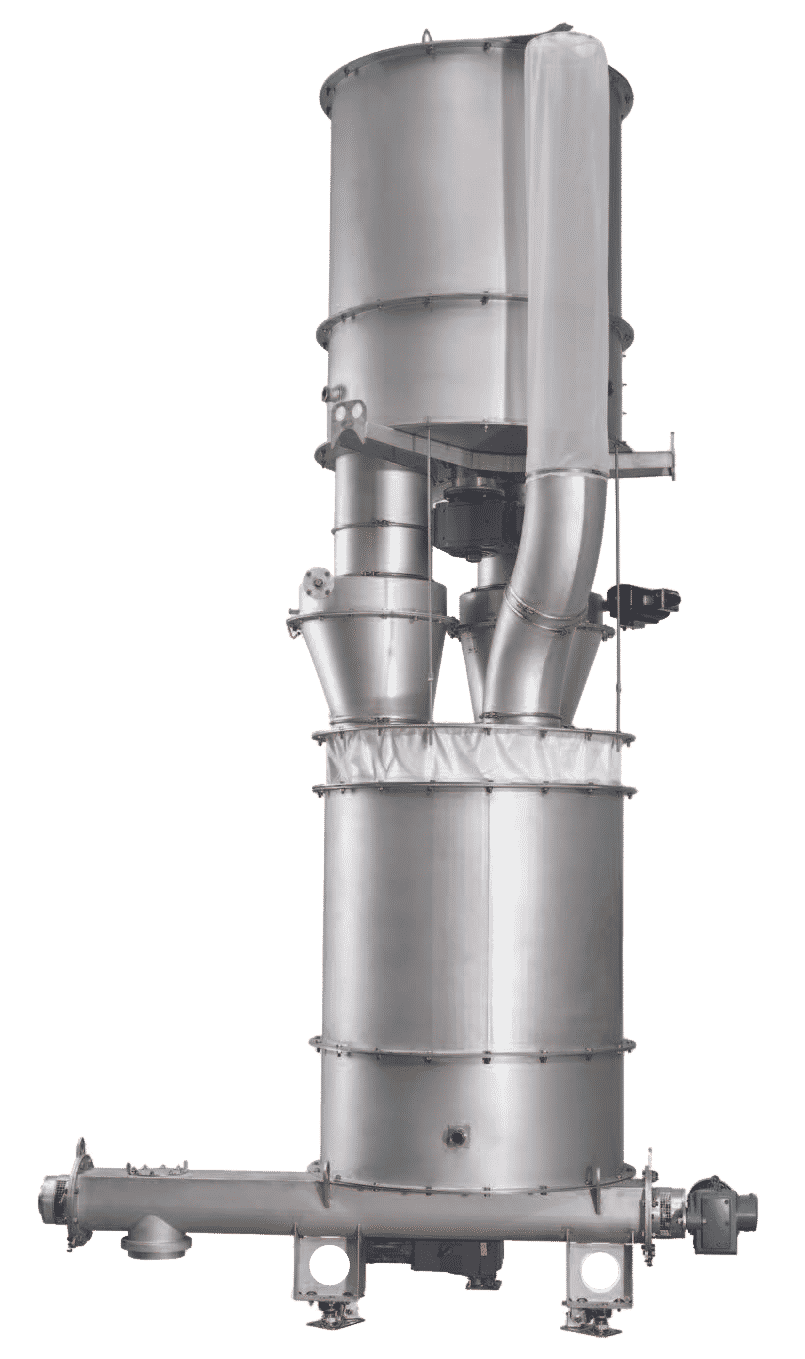

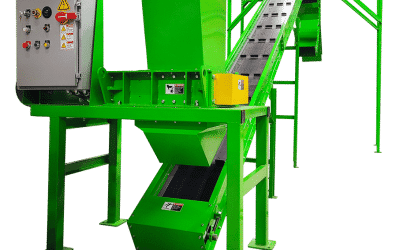

Bulk Feeders – 282 to 1,112 ft³/hr

The bulk feeder is ideal for lighter, more fluffy powdered products. Most popular for plastic film extrusion and compounding, it can directly fill large vessels or maintain load for smaller, downstream feeders. The system is designed to allow easy dismantling for cleaning and is available in steel for more abrasive applications.

Accuracy to spec.

Features:

- Internal Agitator (bottom-driven for balance)

- Double-wound helix feeder (maintains smooth feed at low speeds)

- Modular components (easily adaptable for different speeds and products)

- Tube-in-tube discharge minimizes wear

Options:

- Hoppers: 35, 53, 71, or 88ft³

- Screw Diameters; Feed Rates:

– 5.9”; 176–282ft³/hr

– 7.9”; 353–565ft³/hr

– 9.8”; 706–1,112ft³/hr

Whereas vibratory feeders are better for irregular product and those that would damage or be damaged by feed screws, screw feeders can handle certain products better, such as liquids and viscous or sticky slurries. If your product fits in neither or both categories, reach out and we’ll identify the best solution.

>40 Years’ Experience

From equipment sales to integration and service, ABM Equipment has scaled and optimized systems just like yours. Give us a call or fill out the form below to find out how we can scale your processes and reduce your operating costs.

Equipment | Design | Integration | Service

Related Equipment

Bulk Bag Fillers

Bulk Bag Fillers, also known as super sack loaders, package product for sale or storage. Our Bulk Bag Fillers have numerous convenient features for longevity and ease-of-use, are backed with 24/7 emergency service, and can package up to 3,000 lbs....

Tabletop Flour Mill

Throughputs 66 fine lbs./hr., 165 course lbs./hr. Made In Denmark/EU

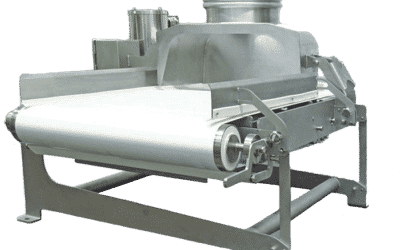

Weighbelts

Weighbelts are flat belt conveyors with weighbars beneath the belt to measure product flow. Knowing product weight and convey-rate, weigh-belts precisely meter product into the dryer by communicating with up-stream equipment and adjusting speed....

Spice Mill

Throughput 220–1,433 lbs./hr. depending on millstone size Motor 2-10 HP (Depending On Millstone Size) Dimensions 53.3" H, 40" W, 27.6" L Millstone Sizes 300, 400, and 500 mm Made In Denmark/EU

Herb Shredders

Shredders slice herb it into small, homogenized particle sizes in preparation for drying. Shredders are preferable over mills for wet product because mills crush instead of cut; crushing inflicts unnecessary damage, makes screens difficult to...

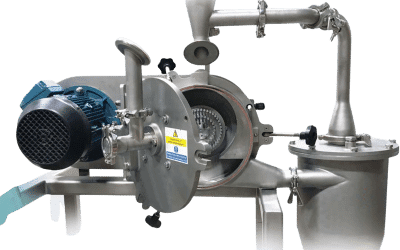

Universal Mills

Options The Universal Mill can either be located at high elevations or at ground level. It is linked to the milled-powder collector, which can be connected via hopper or external filler-receiver (see below). Cryogenic configuration (see below)...