GRAIN-IN, GRAIN-OUT

We’ve got it handled

Ingredient handling for distillers, grain handling for maltsters, or malt handling for brewers, ABM Equipment is the leading provider of robust, efficient systems to the industry.

New 2-Roller Mill Coming Soon!

Borne from brewers’ requests for features, find out how this new mill is set to handle the problems typical of brewery mills!

Grain & Malt Handling

ABM Equipment takes your project from concept to production with collaborative AutoCAD design, turn-key integration, and 24/7 service. Every flange connection is designed to be practical, solid, and movable for future growth.

In-house engineers and fabricators work with your team to deliver custom, cohesive systems that save money and spare headaches.

Intake

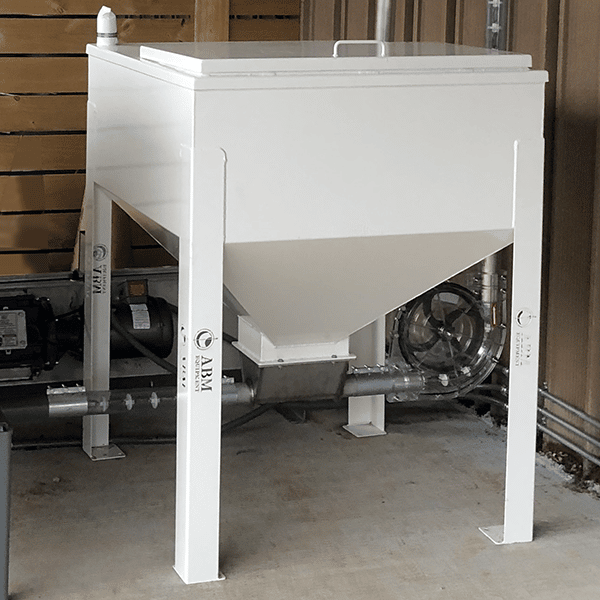

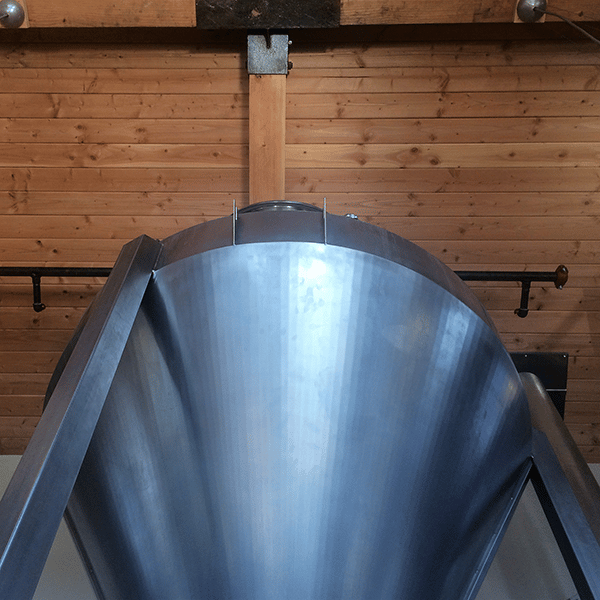

SPECIALTY HOPPERS

We make all varieties of hoppers with custom features, shapes, and colors. Used for specialty brews and small breweries, specialty hoppers allow smaller portions of malt to be staged before grinding.

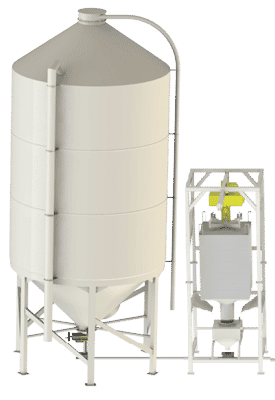

BULK BAG UNLOADERS

Our specialty BBUs are the best in the industry. They facilitate the most efficient use of supersacks and come in low-profile, hoist & trolley, stainless steel, and other options.

Conveying

AUGERS

An auger is a tube with a corkscrew-like shaft snaked through it. A motor rotates the shaft, progressing the grain. Flex augers use PVC tubing and a flexible shaft allowing angled sections. They are the cheaper conveying method but are hard on product and not modular.

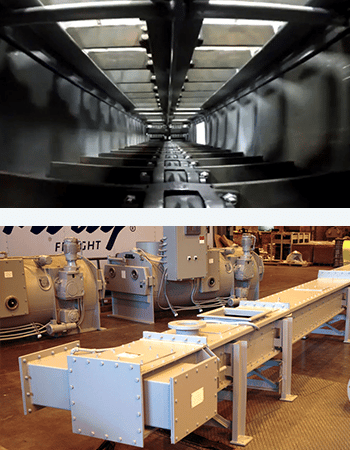

CHAIN DISKS

By pulling segmented disks through a tube, chain disk conveyors can transfer grain in special conditions like about consecutive tight corners. They can move grain more quickly than augers and are gentler on grain, improving yield.

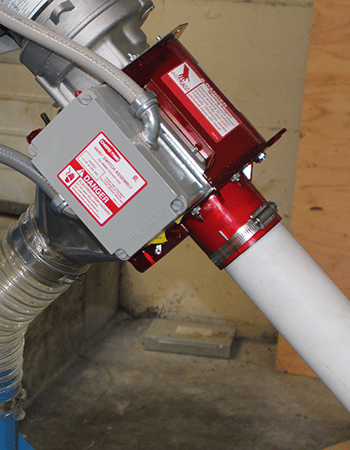

PNEUMATIC CONVEYORS

Using compressed air, pneumatic conveyors are for larger breweries or silo fill lines. They can move grain upwards of 4000 feet per minute but are expensive and very hard on product, especially malt. For this reason they’re typically used silo-mill or at low pressure between truck and silo.

CHAIN CONVEYORS

Chain conveyors are the fastest, gentlest method of conveying grain but are rarely used because they take up a lot of space and are expensive. But when possible, they deliver the highest yields and consistency possible. Numerous chain configurations are available, allowing them to go up steep inclines.

Milling & Weighing

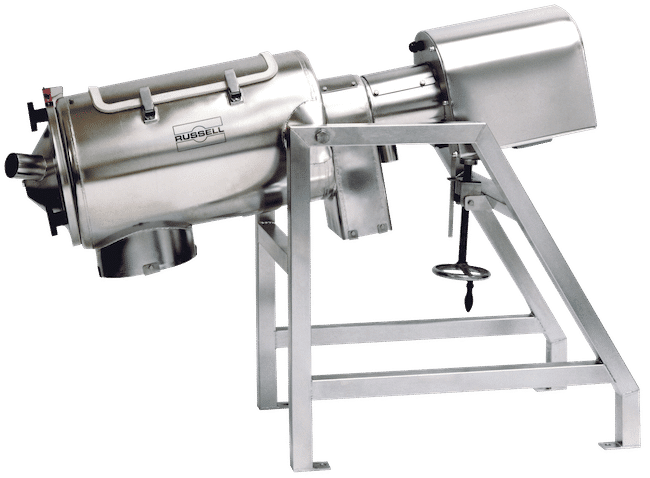

MILLS

The more finely malt is milled the greater the extract production but the more likely you will run into problems during wart separation and degradation during conveying. We carry up to quad-roller mills which grind up to 8,000 lbs./hr.

SCALE PACKAGES

Our sister company, A-1 Scales, designs and calibrates all of our systems. The most common method used for automated portioning is a scale hopper, but different applications can call for different solutions.

Spent Grain

SPENT GRAIN PUMPS

Spent grain is heavy and rich in bacteria as it was soaked but not boiled. Pumps are expensive but keep the workspace clean, save backs, reduce labor, and mitigiate liability. Dry runs and moisture inconsistencies make things difficult. but there are solutions.

SPENT GRAIN SILOS

Spent grain silos are smooth-walled stainless or powder-coated mild steel with steep (typically 60°) bottoms. Ideally they will be raised enough that trucks can get under them and will store 2 days’-worth of grain in case pick-ups are missed or there are unexpected increases in production.

Distiller’s Dewatering Centrifuges

The best-designed models on the market, these specially-configured models feature a number of convenient design considerations and reduce the moisture of spent grains to as low as 65%.

Ancillary Equipment

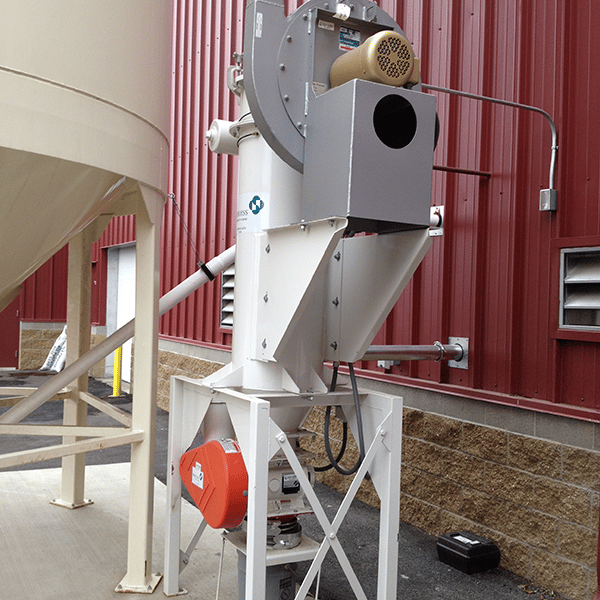

DUST COLLECTION

Small, contained mill rooms can get by with frequent cleaning, but excessive airborne debris is hard on the lungs and creates cleanliness and safety issues, particularly when wet. Our solutions reduce hazards and always satisfy the latest NFPA regulations.

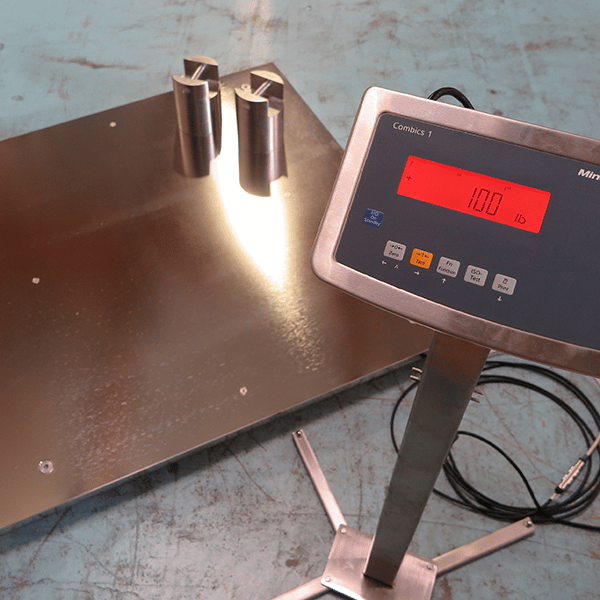

FLOOR SCALES

Simple floor scales are used for special batches, smaller quantities of ingredients added manually, and for small breweries. Bench scales and analyzers are also available.

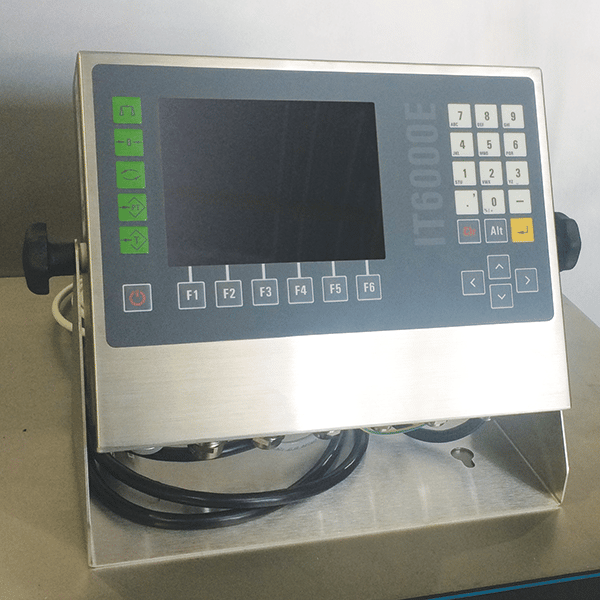

PROCESS CONTROLS

Controllers allow automation of various process functions. These controls can be as complex as needed and can dynamically auto-correct different stages of processes. Our standard solution comes with multiple inputs and pre-programmed recipes.