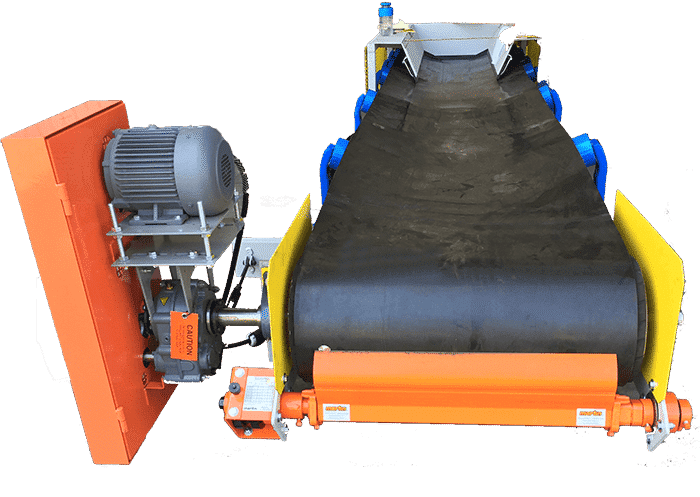

Trough Belt Conveyors

Trough conveyors are belt conveyors where the bed or idle pulleys are shaped to bend the belt and cup the product. This improves the belt’s carrying capacity by helping the product mound and provides a degree of protection from elements and jostling. Trough conveyors are used in practically endless applications, but most often in bulk and/or outdoor industries such as mining & agriculture.

Details

Ideal Applications

Trough conveyors are great all-around solutions for short runs where product may not be in perfectly consistent conditions. They’re also ideal for applications where product needs to be contained but walled beds can’t be used because of their contact with product or cleanability issues:

- Abrasive Products – Stone, minerals, and metals will eat through walled conveyors and screw augers.

- Delicate Products – Walled conveyors or screw conveyors can bruise and cause crushing of some fruits, vegetables, etc.

- Sanitary Applications – Hard angles and crevices require a lot of man-power to clean thoroughly.

Trough conveyors have significant advantages in many uses but they require more maintenance in the long-run than walled flat belt conveyors. First, with extra moving parts comes extra wear-and-tear between the belt and the rollers and within the rollers themselves. Second, trough conveyors typically rely on negative drive (tensioned belt around the drive) which means 3 things: more wear on the belt, tension must be monitored and adjusted, and there is a lower maximum weight threshold when compared to flat, positive drive conveyors.

Materials

Like flat beds, trough conveyors’ belts are available in a wide range of materials depending on the application. The exclusions are belts that can’t handle flexing or tension such as PVC or modular configurations. Paper filter belts are often used to allow liquid to drain through solids, such as oil through potato chips.

Color

For many applications it’s important to ensure your belt’s color contrasts the product’s as much as possible. This is to allow your quality control staff or color sorters to more easily catch belt shavings that may come off during a mishap. Having a white belt with a black product, for example, will make even dust visible should a belt start to wear prematurely.

Supports

Open Frames

Open walls have no sides and often come with belt lifts, both features making cleaning much easier. For this reason open frames are popular in very dirty and very clean applications.

Closed Frames

Closed frames are used for many standard applications because first, though it’s harder to get dirt out, it’s usually harder for dirt to get in. But the big selling point is it’s much cheaper to bend a side rail and weld it in than construct the pipes and supports needed for open frames.

Trough Belts Vs. U-Belts Vs. Tube Belts

Trough belt conveyors are similar to but different from U-belts in that they don’t have exceptionally high walls. The chief goal of trough conveyors is to maintain or improve product capacity, u-belts are designed to balance security and capacity, and tube belts maximize security alone. When slope becomes a determining factor between the three, trough conveyors can use cleated belts

Security

Tube Belts > U-Belts > Trough Belts > Flat Belts

Capacity

Trough Belts > Flat Belts = U-Belts > Tube Belts