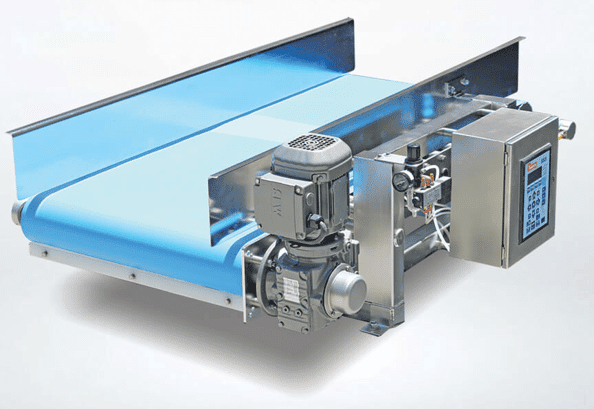

Used Weighbelt For Sale

Very lightly used Thayer MWF-OS weighbelt feeder with stainless frame and contact surfaces with 2B finish.

- Originally specified for undried cut hemp at 20,000lbs/hr at 35lbs/ft3 bulk density.

- Drive Motor: 460VAC/3 Phase/60 Hz; Instrumentation: 100-240VAC/1 Phase/50-60 Hz – (350W max).

- 82 inches centerline of head pulley to centerline of tail pulley length.

- 24 inch belt width.

- Left- or Right-hand belt removal.

- 304 stainless steel frame construction with mill (2B) finish.

- 304 stainless steel product contact surfaces with mill (2B) finish.

- 5-inch diameter “V” groove head pulley drum with FDA approved smooth Nitrile lagging.

- 5-inch diameter “V” groove, self-cleaning, caged tail pulley.

- Latch operated telescoping belt take-ups.

- FDA approved stainless steel bearings.

- Full length product containment skirts with fixed gap gradient.

- 24 inch wide FDA approved 2-ply cotton/polyester endless belt rated tensile strength of 28 PIW complete with white Buna-N top cover, friction bottom and “V” groove guide. Belt rated for material temperatures from 20º F to 212º F.

- Counter-weighted UHMW blade belt scraper.

- Blade style weigh bridge with electronic load cell.

- Weigh Bridge alignment tool.

- Hollow shaft velocity encoder.

- Tail pulley guards.

- Calibration test weight with onboard storage.

- 200 mm H x 150 mm W x 120 mm D Type-4 / IP66 polyester powder coated mild steel enclosed Universal Junction Box (UJB) factory mounted to weigh belt frame and pre-wired to load and speed transducers.

- 5 HP flange mount, right angle SEW Eurodrive helical-worm gearmotor with 6:1 constant torque speed range.

- Gear motor drip pan.

| Make | THAYER |

| Model | MWF-OS-24 |

| Throughput | Specified for 20,000 lbs./hr. |

| Power | 460VAC/3 Phase/60 Hz; Instrumentation: 100-240VAC/1 Phase/50-60 Hz – (350W max) |

| Width | 24″ |

| Made In | USA |

Notes

- When standing at inlet of weigh belt, watching material move away from you, drive can be installed on the left or right side of weigh belt frame.

- Provides an accuracy of ±½% of totalized weight based on a minimum sample of one (1) minute or two circuits of the belt, whichever is greater or ±¼% to ±1.0% of set rate at 2 sigma based on 30 consecutive one (1) minute samples. Accuracy may vary depending on material flow characteristics.

- THAYER Scale S52i Instrumentation System (Product Code IN-S52i) system complete with: 300 mm H x 250 mm W x 150 mm D Type-4 / IP66 painted mild steel enclosure with foot mounting kit and slotted screw enclosure latch.

- Embedded PC (EPC).

- Operator Interface (OI).

- Mass sensing processor.

- Velocity sensing processor.

- Belt Integrator Application Software.

- Native Ethernet/IP – Modbus/TCP (field wiring to RJ45) Device Level Interface.

Instrumentation Notes:

- S52i provides rate measurement and totalization. Rate control, if required, by user’s PLC.

- S52i must be mounted within 1,000 feet (total wire length) of belt scale.

- S52i provides the following discrete inputs and outputs:

- Analog Outputs: AO 1 (User Selectable)

- Digital Inputs: Drive Status (Factory Set)

- DI 1 (User Selectable)

- DI 2 (User Selectable)

- DI 3 (User Selectable)

- Digital Outputs: Totalizer (Factory Set)

- DO 1 (User Selectable)

- DO 2 (User Selectable)

- DO 3 (User Selectable)