Material Handling Equipment

Simple installations to complete system design and integration, we help move bulk dry solids, powders, and slurries efficiently. Whether food, pharma, or industrial, we identify and deliver the best solution for each product. Below you’ll find a far-from exhaustive list of popular equipment. If we seem like a fit but you don’t see the exact piece you’re looking for, fill out the form below; we can improve nearly any system.

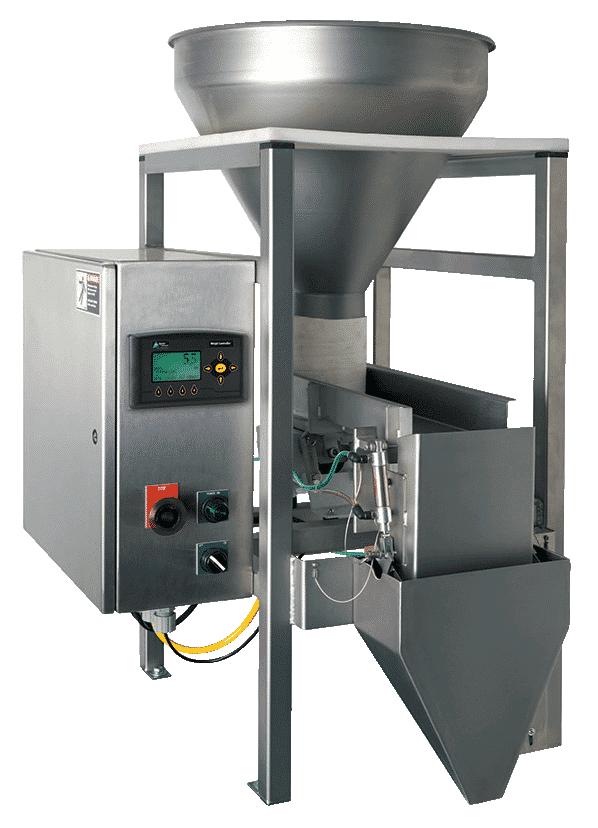

Screw Feeders

Screw feeders use rotating screws to move virtually any product which is not too stringy or abrasive in a controlled fashion, and can be volumetric or gravimetric.

Vibratory Feeders

Vibratory feeders use vibration to fluidize non-sticky, free-flowing materials and are available in multi-head configurations.

Flat Belt Conveyors

ABM provides flat belts of numerous makes and custom-builds them for special projects. They can be made of a wide range of materials and fitted with custom reject systems.

Trough Belt Conveyors

Trough belts use angled beds or rollers to prevent product rolloff due to uneven terrain or environmental factors. Numerous indoor and outdoor models are available.

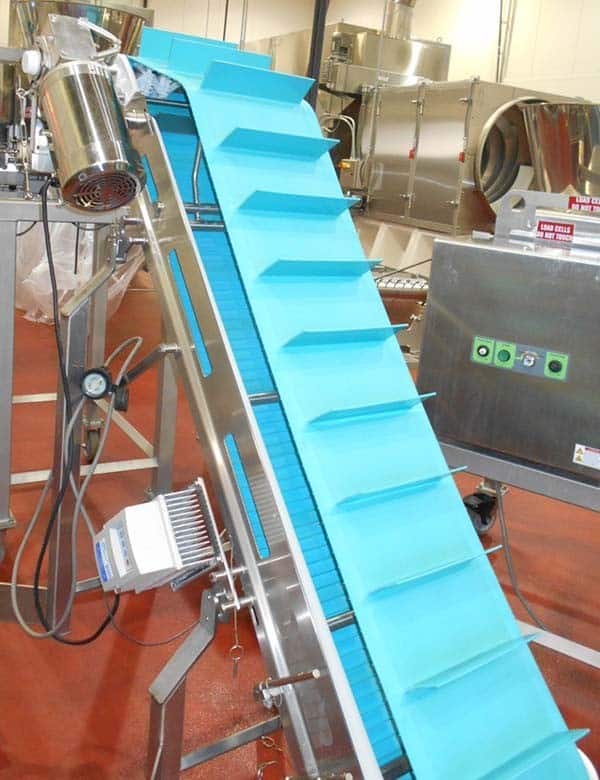

Cleated Belt Conveyors

Sometimes called crossbelts, cleated belts’ spines provide support up steep slopes. They often have open sides, allowing product to be rejected or sorted cross-wise.

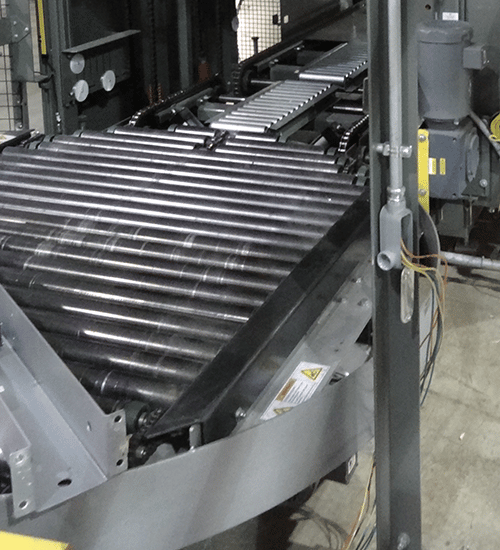

Roller Conveyors

Roller conveyors use in-line rollers which allow gravity or momentum to carry product to its destination. They are typically preceded and/or followed by traditional belt conveyors to control speed. We can source, customize, or fabricate roller conveyors for a wide range of applications. As with all conveyors we provide engineering and integration.

Screw Conveyors

Screw conveyors are a versatile catch-all solution for many products excluding the stringy, abrasive, or particularly fragile. Applications where a screw conveyor will provide advantages are those where multiple discharges along a single line are required, product needs to be carried up steep inclines, or it needs to be fed precisely. Shaft-less models are available for clumpy or uneven product, and closed-trough models are available, even vapor-tight.

Chain Conveyors

When space allows, chain conveyors move product more quickly and gently than other options. They can climb steep slopes and handle abrasive and high-temperature products with minimal wear. Depending on the type of flight or paddle configuration chosen, the product can be conveyed up slopes as steep as 90°.

U-Belt & Tube-Belt Conveyors

U-Belt & Tube-Belt conveyors use rollers to wrap partially or completely around product. This allows abrasive material to be conveyed securely over great distances and rough terrain. They are most commonly used in large-scale applications like aggregates and agriculture.

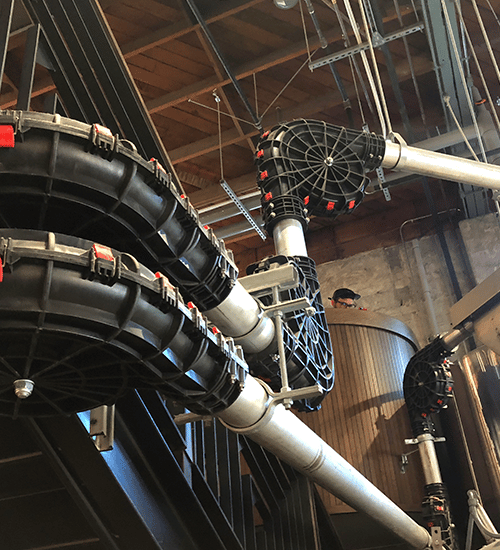

Tubular Drag

Also known as chain-and-puck, this method uses spaced-out pucks to drag product through a tube. Product is gravity-fed in, dropping between the pucks in the top, and gravity-fed out via cut-outs on the bottom. This method is effective, gentle on the product, and can go vertically and about tight corners. Chains are preferred over cables because they are cheaper and don’t wind up over time.

Augers

Auger conveyors, or screw conveyors, employ turning screw-shafts in tubes. Straight augers are like screws with disproportionately large threads, and flex augers are like screws with only threads. This allows transference about wider corners at the cost of efficiency when sloping too steeply. Augers are used for bulk dry solids such as animal feed and grains in brewing and distilling applications.

Pneumatic Conveyors

Pneumatic systems can move product upwards of 1000 ft/min, but are rough on product and require discharge gates out of silos and bins to allow for pressure differentials. The choice between dense and dilute phase will be determined by your product’s density, abrasiveness, consistency, and resiliency, so talk to one of our experts to discover which is best for your application.

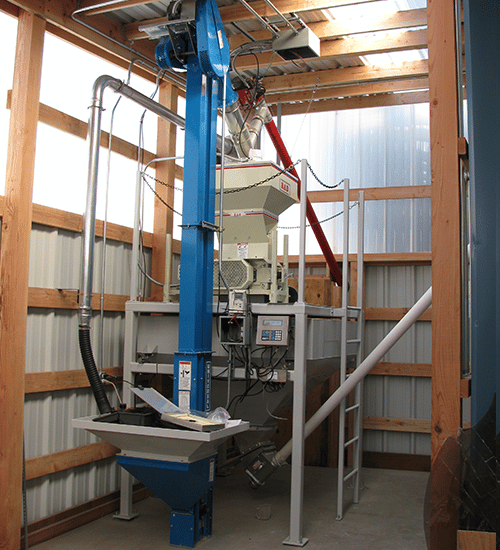

Bucket Elevators

Bucket elevators move product vertically without requiring large footprints. They’re most useful when multiple steps in a process are gravity-fed but share the same floor, and most popular in large-scale applications like agriculture and aggregates. Bucket elevators have been replaced by chain disks for many applications but are still viable for a number of them.

Vibratory Conveyors

Vibratory conveyors use vibrations to move bulk materials. These conveyors are commonly used in industries such as mining, pharmaceuticals, food processing, and agriculture, where the efficient handling of materials is critical to maintaining productivity.

Spiral Conveyors

Spiral conveyors move whole units of product vertically while conserving space. Spiral conveyors are available in single or multi-lane, with your choice of materials from stainless to plastic. They are also available in vibratory configurations to safe further space.

Magnetic Conveyors

Magnetic conveyors use magnetic fields to transport and manipulate bulk materials either by moving a magnetic belt or gripping ferrous materials through the belt for sorting. These conveyors are commonly used in industries such as mining, recycling, and manufacturing, where the efficient handling of materials is critical to profitability.

Work Bins

Work bins provide a convenient place to stage or work with product between processing steps. They are usually custom-made due to the wide range of dimensions and features that can be ideal for their uses. They can be stainless, carbon, or poly.

Bulk Bag Unloaders

Bulk bag unloaders stage product by the 2,000 lb super-sack. Our proprietary designs allow them to fit in tight spaces and deliver the product efficiently and simply. For specialty applications, hoist & trolleys and stainless construction is also an option.

Silos & Grain Bins

Silos are available in many standard shapes, sizes, and materials, but can also be made-to-order with custom discharge gates. When silos are needed but space is an issue, we can help with zoning permissions and creative workarounds.

Level Indicators

From simple models employing a weight on a cable to more complex models utilizing radar, sonar, laser, or other methods, there is a level indicator perfect for any product or application. BinMaster’s level indicators conveniently interface with a variety of controls and remote displays.

Contact Us

Reach out for a quote, more information, or just to talk about your process. We love discussing new ideas and want to hear about your application.

"*" indicates required fields

Visit Us

13911 NW 3rd Ct.

Vancouver, WA 98685

Contact us

(503) 248-0711

frontdesk@abmequipment.com

Office Hours

M-F: 8am – 5pm