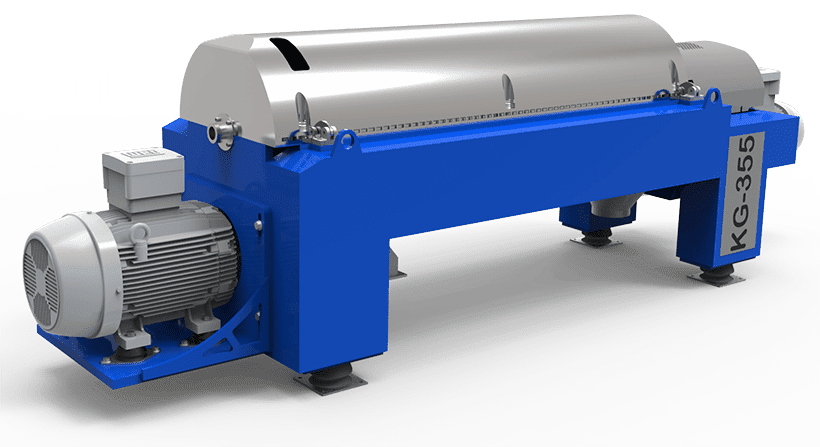

Decanter Centrifuges

Operational Advantages

Energy recovered from the internal conveyor offsets energy consumption of bowl motor

No screens or filters

CIP

Removes solids down to 20 microns

Does not crush cellular walls (extracts fewer waxes and lipids than screw presses)

98–99.5% solids recapture

Features

Auto-run & granular control PLC

CIP (Clean-In-Place)

Tungsten-carbide wear protection on scroll-conveyor

316 stainless contact surfaces

Painted mild steel frame and case

Custom vapor seals retrofitted to casing and feed pipe to assist with vapor tight design

Special scroll-conveyor design modification to help capture “floating” solids

Floaters disk addition to scroll-conveyor

Vibration switch

40 HP main-drive motor, rated Class 1. Div. 1, 1800 RPM, 460-480V/3/60

15 HP back-drive motor, rated Class 1. Div. 1, 1800 RPM, 460-480V/3/60

3rd party peer reviewed by PSI approved for ethanol, heptane, and isopropyl solvents

Rated for use to -60C

System Control Features

Automated drive and control system

PLC-coordinated drives & supervision for granular control, if needed

NEMA 4 freestanding enclosure

Auto-differential software

Optional Stand Features

Painted mild-steel construction

8’ clearance between solids discharge and ground

Collapsible safety rails

Stairwell with safety rails

Built to OSHA standards

| Bowl Size | 8.25” x 28.75” – 18” x 77” |

| Capacity | 270 dry #’s per hour – 3,275 dry #’s per hour |

| Contact Parts | 304/316 stainless steel with viton seals |

| Fittings | Sanitary tri-clamp |

| Max. Speed | 3,150 – 5,100 RPM |

| Max. G-Force | 2,395 – 3,051 |

| Weight | 2,596 – 7,623 lbs. |

| Dimensions | 93” L X 21” W x 30” H – 179” L X 43.25” W x 40” H |

| Made In | USA |