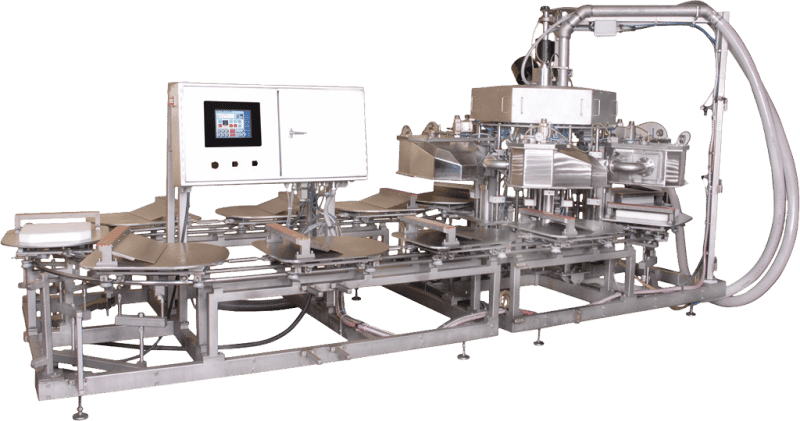

Rotary Thermoformer

Features:

Reduced Operation Cost:

- Patented sealing system

- Water-cooled hold down with continual temperature sealing component. Reduced “pulled in” edges and minimized replacement of sealing components (6-8 months replacement time based on average production schedule)

- Seals through all bag thickness, creases and contaminates

Reduced Maintenance Cost:

- 300 series stainless steel construction

- Designed for food packaging heavy wash-down environment

Reduced Downtime:

- Simple-to-maintain and repair (wear parts are designed for accessibility without complete disassembly)

- Advanced electronics

Faster Production:

- Averages 38 packages per minute

Simple Operation:

- PLC controlled using a 10” touch-screen display

Rotary Thermoformers include:

- Full programmable PLC with readable diagnostics

- Accessible USA parts

- 1 year or 1 million cycle warranty

- Additional optional hardware at hand every day at alike savings

- Commissioning by a factory technician

Rollstock die-lifting system – Stock 4-inch pneumatic cylinder with reliable, straightforward design.

In-stock parts – Rollstock keeps all parts in-stock, save for rare times when there’s a run on an item.

Rollstock service – No-charge techinical support on 800# (95% of service calls are resolved in less than 15 minutes over the phone).

ABM service – 24/7 support is provided for emergencies with technicians often able to dispatch within 24 hours.